So it turned out that in the garage next door to the car stored anything: a bicycle, summer or winter tires for the car, tools and even conservation. Drills, hammers, spare parts, bolts, nuts, power tools - All this is necessary for each owner of the car. Immediately found shelter and old chairs, lockers, broken technique and even outdated refrigerator model. All this trash could have been sent to the garbage, but each self-respecting owner simply did not rise to get rid of many years of history and part with a part of his life. Calling into the garage without problems - the task is not from the lungs. Sometimes you have to unload something to get off freely and do nothing to hook. Agree, the picture is familiar. In almost every garage, all these things are adjacent to the car. To drive out your "iron horse" without any problems, it is necessary to think about losing all the tools and other things in the garage, as they say - on the shelves. In order to do not look for the desired screw, a screwdriver or part during repair, we offer to make a metal shelf metal rack.

Content

Have you evened to look at a huge curiosity in the garage where the perfect order reigns? Someone will say that it is impossible, and someone will give a good advice, how to use free space in the garage at the maximum.

Types of racks in the garage

What is a rack? This is a vertical metal frame design, on which horizontally installed shelves are placed. If we are talking about warehouse metal racks, the design is intended to withstand heavy loads. We can store heavy and oversized goods on such racks. In general, everything that can fit on this shelf.

The width and height of the shelf varies and depends on the size of the room.

Collapsible metal racks - the most optimal garage option. On the market a wide range of racks with different height and width of the shelf. They differ from the fixed structure so that at any moment it is possible to make out the shelf and the whole rack to rearrange to another location. This is particularly advantageous when the scheduled major repairs in the garage.

How are collapsible metal shelves: made of perforated reinforced metal brackets on stable legs. Gather such racks in place, the elements are joined corners. Shelves can be placed at any level, depending on the filling rack. For example, if you need to organize the storage of old tires, for these purposes it is best to allocate 2 shelves, and all the rest: oil and other technical fluids - to place on another shelf.

An example of a metal rack with a photograph:

Also on offer can be seen and mobile design, equipped with wheels. Just such a model of the rack most in demand because unload shelves do not have to if you want to move it from one place to another. Simply move the entire shelf and go about their business. The only caveat - note the weight that can withstand such a design.

Metal shelving box for a warehouse is designed to store small fasteners and spare parts. Such racks are very convenient because they rotate and something resemble a rack for selling CDs or printed products in supermarkets. To find the desired tool or bolt, you need to scroll through the multi-tiered shelf clockwise. Such an option is very convenient for storing small things, it is only important to systematize the entire tool so as not to look for, in which drawer it lies.

Even for the organization and storage of instruments and materials in the garage, you can find inexpensive metal racks for sale, which, most likely, cannot be called racks. This is a mounted shelf, which can be attached almost under the ceiling throughout the perimeter of the room. Just need to take into account the dimensions of the vehicle to drive and leaving the garage, do not hook the shelf with the tool.

Suppose such shelves with low weight than metal racks, so heavy items on such shelves are not placed.

Thinking on how to organize order in the garage, we recommend making metal racks yourself. It turns out very cheap, as you have to spend only on materials. And the tool is in the garage for each owner.

How to make a metal shelving for storing tools and spare parts

Before you begin to acquire all the necessary, it will not hurt everything thoroughly: what load should withstand the homemade rack, how many items and what volume will be placed on the shelf. It is also necessary to take into account the free space that can be allocated to the installation of the rack. Therefore, you need to start with measurements and drawings. And for this you have to visit the garage to make measurements.

What to do if there is no place in the garage in the garage? We have to roll the sleeves and throw away what is really no need. Otherwise, no rack will fit. Make measurements with a construction tape measure: you need to know the height of the metal design and width. An ideal solution is to free the central wall in the garage to place several racks in the width of the room. As for the height of each shelf, it is individually and depends on what is planned to be placed on each shelf.

Tip: The lower shelf is desirable to make high to store oven and heavy items: rubber, spare parts, canisters for gasoline, tanks with technical fluids. All that is hard to raise to put on the upper shelf.

How to calculate the amount of material:

- Measure the height of the rack and width.

- Now you need to decide on the design depth and make a drawing on paper.

- From the obtained figures you need to take 15 cm on each side to make it convenient to collect the rack in place.

- The height of the rack is any, but it is best to take all the free space to the ceiling. Shelf height: lower up to 1 m, all subsequent from 20 cm to 60-80.

- The width of the shelf is standard 1 m, but one can decide on 1.5 m, provided that it will not be stored too heavy load on such shelves. But it is better to stay on a width of 1 m.

- The depth of the shelving and shelves, respectively, is 60 cm. No longer needed, because it will be very uncomfortable to get something with a deep upper shelf. And vice versa, if you make a small shelf in depth, then you will not place a lot on such a rack. Therefore, the optimal option is a rack with a depth of 50 or 60 cm. You can make a separate rack, with a depth of a 30 cm shelf to store fasteners and a hand tool.

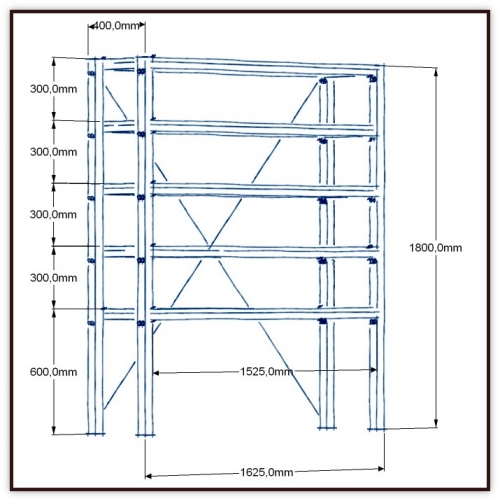

Approximate drawing of a metal shelving:

How to make a metal wired rack

The most optimal option is to make a metal frame, and the shelves are from wooden boards.

What instruments can come in handy in work:

- roulette;

- pencil or marker;

- building level;

- hoven: for metal and wood;

- bulgarian;

- screwdriver and drill.

As well as a metal corner, fastening material and wooden planks for shelves.

What should be considered primarily in the manufacture of the rack: so that the shelves are not in contact with the sockets. Observe safety equipment!

Procedure for work:

- In order to collect racks, use the metal corner. Also suitable material for racks is a cross section of a "rectangle" or a channel.

- Corner is suitable for transverse racks. It is possible to manufacture a rack from corrugated metal. But this option is too time-consuming.

- Metal or metal corner need to cut into segments, according to the drawing, collect the rack right on the spot. If the design is collected on the fastening element, then the assembly is made near the wall. If you plan to work with welding, then all parts are collected on the floor, and then the design must be raised to install on a permanent place.

- The prefabricated metal rack does not require refund, that is, it is not necessary to paint a metal corner. You need to make a rack and install wooden shelves. If the design is welded, then you need to handle the finished rack with the primer liquid, paint in the desired color.

Important: After assembly, check your job: the rack must be durable and stable. If the floor is uneven, then this problem needs to be eliminated, and the rack itself for its own safety, fasten to the wall.

This may be the rack in your garage:

Advantages of homemade metal rack

If we consider the advantages and disadvantages of the racks of our own manufacture, then we can say that this is an excellent savings of the family budget and the ability to make the width, height and depth of the design according to individual measurements.

What are the pluses of metal racks:

- Strength. Such a rack will last several decades, and if you cook the shelves from the sheet metal, then and your great-grandcomnces can be enough.

- Temperature differences, fungus and mold, moisture, technical fluids (gasoline, oil, solvents, etc.) - all this will not spoil and will not affect the functionality of the rack.

- It is known that the metal is not lit, so we can say that with metal racks made by your own hands, a long service life.

And disadvantages? It turns out that they also have, but not significant - will have to make maximum effort and how to try to make a high-quality rack with their own hands.

And how to make a metal rack, we suggest to refresh your knowledge and see this video tutorial: