The lack of sound insulation of the premises in a modern panel house causes a lot of inconvenience to the residents. The audibility of what is happening in a neighboring apartment sometimes makes you doubt its isolation from what is happening. There are few options to create comfortable living conditions: go to a private house or make Zuvukoisolation of the ceiling, walls and floor. Let's talk about how to fulfill the first paragraph of the plan.

Content

Sound insulation of the ceiling in the apartment. The cost of work in contractors

The easiest way to call professional installers and order and order soundproofing. Pay work and enjoy silence and comfort.

How much work will cost the owner depends on the material and the method of sound insulation:

- The use of perforated gypsum or zeolite plates costs an average of $ 7 to $ 40 per m 2.

- The use of mineral wool costs an average of $ 15.5 - $ 30 per 1 m.

- The use of thermal insulating non -woven material for a hinged ceiling costs an average of $ 50 to $ 240.

- Installation of a company acoustic ceiling from $ 180 to $ 300 per linear meter.

The work on improving the ceiling is not complicated, most of the amount is deducted for the material, but 30-40 % of the price set by the customer goes to pay for the labor of the employee.

For an economic and artisan person, it will not be difficult to do all the work on the sound insulation of the apartment on their own.

Types of sound insulation

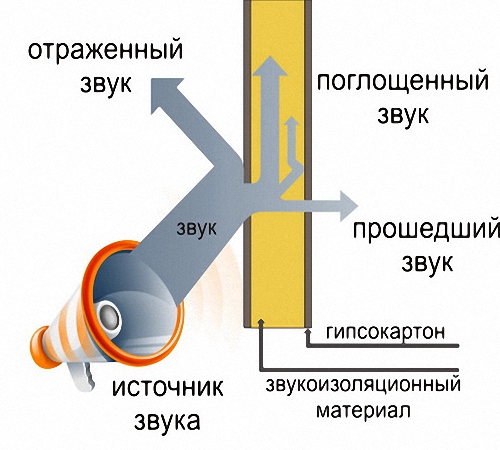

The essence of sound insulation is to create an obscuring barrier for the sound waves coming from the source, weaken or completely neutralize them. The thickness of the barrier and the technical characteristics of the material for catching will affect the effectiveness of sound absorption. Experts guarantee a decrease in noise by more than 40% when using modern noise -absorbers.

Isolation materials produced by modern manufacturers are divided into such groups:

- Organic insulators. These are polystyrene foam, fuel and fifth, chipboard, ecovata. They are used for soundproofing utility rooms: garages, sheds, hangars, temporary households. Advantage: The cost of 1 m2 of $ 1, constant availability, ease of installation. Flaw: Easily burning material.

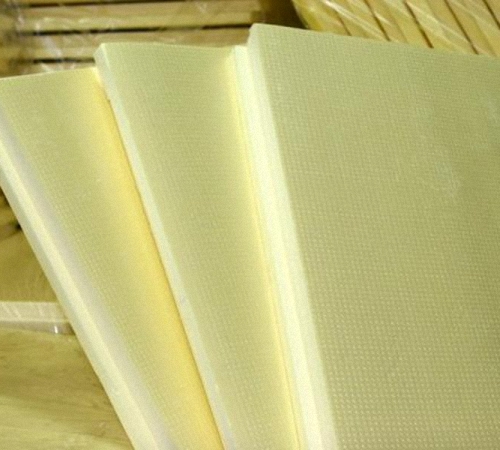

- Extruded polyethylene foam. Advantages: It creates high soundproofing, resistant to chemically aggressive environments, is not deceived, well captures shock noise. Antipyrene enrichment increases refractory properties. For effective noise absorption, there is enough plate with a thickness of 2-3 cm. The average price is from $ 1.5 to $ 2.5 per 1 m 2.

- Inorganic insulators. Are produced with the addition of components that increase the protective properties of the material to fire, moisture, rot. These are well -known glass wool and stone wool products. Advantages: durability, environmental friendliness, low cost, average price per 1 m 3 is $ 1.2 - $ 30, a large temperature range from - 60 0 up to + 400 0, which is much higher than the indicators provided for in the norms for the dwelling. This quality allows you to use inorganic insulation for industrial premises, hot workshops, bakery, culinary workshops. Mineral insulators are inert to aggressive substances and environments.

- A buttonatic self -adhesive tape. Advantages: Environmental friendliness, high soundproofing characteristic, elasticity, high water -repellent characteristic, long service life.

The choice of material is made independently, taking into account the budget, the characteristics of the material and its safety for health.

Preparatory work. General description of the process of laying a hinged layer on guide profiles

Consider the sound insulation of the ceiling in the house according to a single -layer structure.

Start preparing the ceiling surface:

- Remove the old wallpapers, rinse to the base of the overlap of the old whitewash, remove the putty with a sharp edge with a sharp edge.

- Check the strength of the adhesion of the putty with the base of the ceiling with a light tapping along the old layer. Remove the sprinkling seal.

- Cracks, gaps, seizures that appear are masked by a special sealant, and not alabastr or starting putty. The sealant additionally isolates vibration and noise effects.

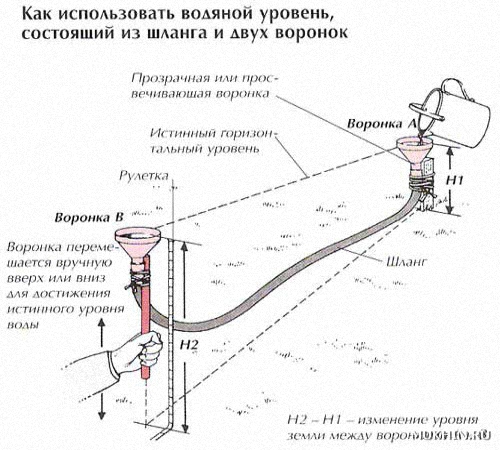

- Measure the corners and check the area of \u200b\u200bthe ceiling for evenness. For these purposes, the most reliable tool will be a water level. It is filled with water to the mark. It leans against one corner, an indicator is noted, then a similar procedure is done in the second corner. The difference in readings is noted on the wall. Each angle is checked, marks are affixed.

Measurements:

The length and width of the ceiling are measured. The length of T-shaped wide profiles and narrow rails is calculated. An important point for building a hinged ceiling design. Isolation materials have their sizes, which will have to be taken into account when buying. First, the number of panels or elements for the suspended ceiling is calculated on the total area, and then the amount of insulating material is calculated. The dimensions of the finishing material determine the placement method: across or along the room.

Having selected the material, they prepare tools and connecting elements according to the general list:

- Screws, suspensions, self -tapping screws.

- The guide strips - the amount determined after measurement.

- Adhesive drug.

- Drill, punch, manual drill, screwdriver.

- Hammer, pliers, scissors for metal.

- Scab, knife, rail, rubbish.

- Legist for construction goats.

- Selected noise insulator. Volume, meter or quantity determined after measurements.

- Finishing material. The quantity is determined after measurements.

- Leveling, level, roulette, pencil or coloring lace.

- Spatula for sealing joints, screws, corners.

- A roller or brush for priming.

- A mixture for putty.

- The container for the preparation of a wet mixture.

- Grouting with sandpaper.

All of these tools can be replaced with improvised households.

Installation of the frame:

- The guide profile is installed. It is attached along the perimeter of the ceiling to the base of the dowel or a long self -tapping screw around the perimeter.

- From the attached rail, the indentation is made along the width of the sheet of drywall or other finishing material, a mark is placed. This marks a place for a narrow profile, additionally strengthening the sheet.

- The procedure is done to the opposite wall. The reliability of the fastening of the rails and profiles is checked manually. The main thing is to correctly fix the corners in accordance with the verification of the ceiling with a level.

- The mounting profile is attached to the profile with self -tapping screws. The transverse rails are aligned and attached with straight suspensions or suspensions of the “butterfly”.

Puffing sheets of drywall:

- The length, the width of the sheet is sustained, the excess part is cut.

- The sheet is applied to the stuffed frame and a screwdriver or self -tapping screws are attached to the profile and rails.

Advice: The mounting hats are slightly shed into the sheet, the metizes are selected with an oxidized coating. The stuffing process is fast and simple.

Settling sheets of a hinged ceiling:

- The first putty layer is applied with a starting, rough mixture. After drying, the grout with sandpaper is taken and the places of roughness are smeared.

- The second grouting layer is applied with a finish building mixture. The dried layer is treated with grouting with an emery until smooth.

Painting the ceiling:

- Starting to color, decide on the color of a hinged ceiling.

- A properly selected color scheme has a positive effect on the well -being of the residents, decorates the interior, creates the appearance of volume and spaciousness in the room.

- The choice of dye should be stopped on acrylic paints. They are designed without adding organics, solvents, inexpensive in price, have a wide range of shades, are easily applied with a roller or a spray gun.

Video lessons will help to visually imagine work, more closely consider obscure moments:

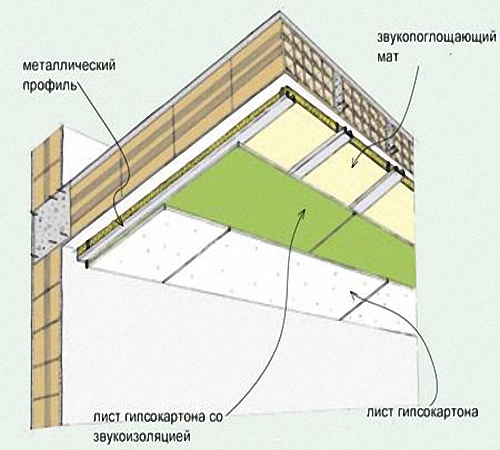

Multi -level insulation of the ceiling

With multi -level sound insulation, work is not carried out on perfectly aligning the surface of the ceiling. Sound insulation disguises minor defects. The main attention is paid to the exact installation of the profile.

To work, prepare tools:

- Reiki guiding profile strips.

- Glue for soundproofing material. A primer under the basis.

- Drill, manual drill.

- Screws, self -tapping screws.

- Working construction goats or staircase.

- Pliers.

- Scissors for metal.

- Working gloves.

- Protective glasses.

- The container for the solution.

- Suspensions.

- A roller with foam rubber, 150-180 mm long.

Working process:

- Wash off the old whitewash from the ceiling, clean the paint. Dry the surface. Set the microcracks.

- Install the guides with the anti -vibration system on the ceiling.

- Dilute the adhesive according to the attached instructions.

- Pour part of the solution into the container, apply a roller to the ceiling. Prepare the insulating material, cut off the piece along the ceiling length.

- Press the insulator to the surface and immediately clamp it with suspensions. Distribute the material with a margin of 1-2 centimeters per wall. Drink the material on the ceiling, make sure that there are no air bubbles between the ceiling and mineral wool. The edges of the next roll are brought up to the glued.

- Net with dowels or fasten the wide T-shaped profiles with self-tapping screws, withstanding the distance between the slats equal to the width of the sheet of the finishing material.

- Fix narrow rails to support sheets of finishes.

- Put drywall. Flow to the profile rails with a screwdriver.

- Lower the joints with a sealant. Spread in 2 layers sheets. Color.

This noise insulation provides protection 20-25% higher than the single-level.

How to make a stretch ceiling yourself

The sound insulation of the stretch ceiling is carried out by pulling a special canvas, tissue material based on polyester on profiles. Visually, the design is simple, which means that it is easier than from drywall. But each process has its own characteristics and subtleties.

Installation of a simple stretch ceiling. Pipe, communications, a room of strictly geometric shape, without niches or protrusions do not pass along the surface. What needs to be prepared for work:

- Material: PVC film or fabric.

- Baget-profile.

- Centimeter, roulette.

- Pencil.

- Water level.

- Folding transport.

- Scabbard or scissors for metal.

- Thermalcenerator, calorifier.

- Scurgery.

- Self -tapping or dowels.

Installation of a simple stretch ceiling:

1. Find the lower corner of the room by water level, retreating 1-2 cm, make marks.

2. Find the zero level around the perimeter of the walls, make a mark.

3. Make the angles measured the folding transport for a flat conjunction of the profile.

4. Prepare a profile rail. Two options are possible:

- the length of the baguette is greater than the width of the room. The edge of the rail is cut at an angle equal to half the corner of the room;

- the length of the baguette is less than the width of the room. One end of the rail is cut at half the corner of the room, and the second is recorded by 90 0 For an accurate fit to the second rail. The missing piece of baguette is taken and the same operation is done with its endings, with a bevel for the opposite angle. Parts of the baguette are glued.

5. Fix the baguette around the perimeter of the wall, verify the level. Perform fasteners with self -tapping screws or dowels.

6. Turn on the calorifer and warm the room to a temperature of 40 and above degrees. Close the windows and doors to the room. Only after installing the required temperature, unwind the insulating material on the PVX basis for a hinged ceiling. Avoid close contact of the insulator with the caloriece. Warm up the film up to 60 0.

7. Start pulling the panel. A basic angle is marked on the film. Start installation with it, then fasten the angle diagonally. Similarly fasten the two remaining corners. Start consolidating the sidewalls. The tissue material also warms up, but another attachment procedure is used: first of all, the sidewalls are attached, the corners are secondly.

Video lesson for consolidating knowledge: