Explosion -proof lamps are special lighting devices that are designed to work in explosive zones. Like other explosion -proof equipment, such lamps differ from the usual specific structure - a strong sealed housing, protective mesh, heat -resistant glass and other things. Why are these lamps are needed, what types and features of their application are we will tell in this article.

Content

Characteristics

Explosion -proof lamps are designed specifically in order to ensure the proper level of lighting in potentially explosive rooms. So, they are used at gas stations, mines, oil platforms, laboratories, storage facilities. The use of any other lighting devices in such places is considered a violation of safety standards.

Their main distinguishing feature from ordinary lighting devices is a very dense connection of parts made, in turn, from high -strength fireproof materials. The shell of such lamps is able to withstand the colossal temperature and pressure, the design provides a lower gasoling temperature, the thermal regime of explosion -proof lamps proceeds in such a way that the temperature of the external parts never exceeds the permissible value (does not heat up). Thus, such lighting elements can not provoke the occurrence of a fire hazardous situation.

Scope

At objects with increased explosion, the use of explosion -proof lamps is mandatory, otherwise safety requirements are violated. Such zones and facilities include all enterprises of the oil processing industry, including gas stations, as well as the places of subversive work, military training grounds, factories producing combustible substances or any paint and varnishes.

If you plan to buy explosion -proof lamps, the choice must be approached extremely carefully, given the specifics of the room and the design of the device itself. It is lighting that gives people not only safety and comfort of movement, but also a sense of safety. This is laid down on a subconscious level, since a person will always go from darkness to light, believing that there is heat and protection. Explosion -proof lamps can provide just such protection and comfort, and even save life in an extreme situation.

It must be understood that these are not just elements of lighting, but the most important factors on which not only the productivity of workers can depend, but their life and fate of production as a whole.

Peculiarities

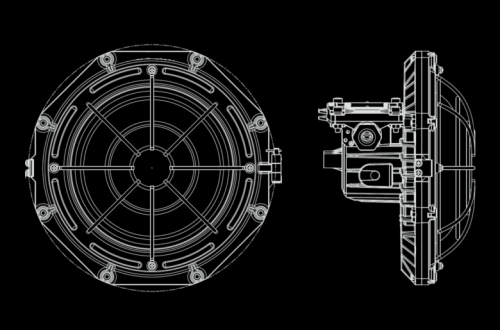

What factors allow explosion -proof lamps to work uninterruptedly in the most extreme situations, when ordinary industrial lamps completely fail? The fact is that, unlike ordinary devices, these lamps are made of incredibly durable materials fastened in a special way. The case, for example, is made of polycarbonate, and reflectors from sheet steel, which helps to maximize the safety of people working at the enterprise.

Protection against mechanical damage is ensured by a hardened case. As a rule, most of these lamps are made of heat -resistant glass. All their parts are connected very tightly, so during an explosion or fire they can withstand colossally high pressure and temperature. It is a sharp increase in pressure that disables the lighting element, and the design of the lamp reduces the risk to zero.

Also, the merit of the structure is to ensure a smaller heat of gas fire and a special thermal regime, in which the external details of the lamp are heated. This excludes the risk of fire hazardous situation. Plus, the wiring is also placed in a special way - it is protected by a special casing, so even if a short circuit occurs, the occurrence of the explosion is practically excluded.

How to choose

Today, the nomenclature of explosion and fireproof lamps is increasing and replenished with new specimens every day. Specialists are constantly modernizing lamps and studying innovative ways of illuminating explosive zones. That is why it is very difficult for an inexperienced person to understand the incredible variety of models.

What to be guided by when choosing such specific lighting:

- First of all, the choice should be determined by the classes of zones in which lamps will be used. It is on the correctness of this choice that the optimal cost, efficiency and reliability of lighting will depend.

- The complexity of the design is all kinds of protective devices (nets, glass, gratings, etc.) and their strength directly affects the efficiency of lighting devices and their lighting indicators. Before buying, carefully study and evaluate the factors that determine the efficiency and quality of electric lighting. For example, if a bright light is needed in the warehouse, then buy a lamp “packed” in thick glass and a lot of gratings will be inappropriate. If a little light is enough for normal functioning, for example, to make out the path in the corridor or mine, then here you can use the lamps described above.

- For the B-PA and VP class, it is better to use lamps for explosive zones, as well as containing a mixture of fibers, air and combustible dust.

- For zones of class B-1, analogues of explosion-proof lamps can be used, which are used to work in rooms with unstable mixtures of gas, vapors and air.

- For zones of the V-PA class, it is permissible to use general-purpose lamps, if a special protective shell is provided for them that does not pass dust into the housing.

- Regardless of the zone class, the degree of protection of the lamps should be no less than PR54.

When buying any lamp, a certificate must be provided in which operational and constructive characteristics should be given. The price of explosion -proof lamps directly depends on the specifics of use.

Classification and types

Explosion -proof lamps are characterized by two safety indicators, which are displayed on the housing or packaging:

- Type “D” - deciphered as “explosion permeability of the shell”.

- Type “S” - deciphered as “special type of explosion protection” and is used for the introductory box of the device. This species shows the degree of execution of the protection of the type “E” and the requirements for protection against the influence of the external environment IP67.

With a similar type of protection, the cable cannot get into the explosion -proper shell, which is a significant advantage for the consumer, because it provides at the same time real protection of life and the maximum of positive operational characteristics. If the cable is inserted directly into the shell of the housing or the introductory box of the lamp, then almost all the responsibility lies on the shoulders of the consumer.

Marking separation

There are the following types of areas of use of explosion -proof lamps by marking:

- 1st level (1EX ...)-are used where you can use second-level lamps (2EX ...).

- Category IIC - are used where you can use lamps of category IIB.

- Lamps of high temperature class - are used where the simultaneous use of lighting devices of a smaller temperature class is permissible. So, T6 lamps can be used where there are lamps T5, T4, T3, T2 and T1, and so on. T2 lamps can only be used in conjunction with T1.

There is also a certain marking according to GOST 15150, denoting the possibility of using explosion -proof lighting devices in macroclimatic zones with sea climate (on the coast, rivers or lakes):

- Y - moderate;

- HL - cold;

- UHL - moderate cold;

- T - tropical dry and humid;

- TV - tropical moist;

- TS - tropical dry;

- TM - tropical marine;

- O - general climate performance (all macroclimatic zones on land, except for very cold);

- M-moderate-cold sea;

- OM-moderately cold and tropical marine sea (used on ships of an unlimited voyage area);

- B - suitable for all zones on land and at sea, except for very cold.

Separation of the OP type of light source

Also, explosion -proof lamps can be divided by type of light source:

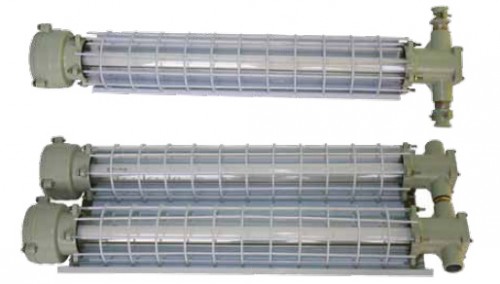

- Luminescent - the main advantage of such lamps is their economy, safety and durability. In the process of manufacturing such devices, a special “explosive resistant shell” is used, which is an explosion -protective electrical part (lamp), isolated from the possibly adverse effects of the external environment. Thus, the possibility of destabilizing the work of the fluorescent explosion -proof lamp from the outside is excluded.

- The incandescent lamp - explosion -proof lamps for incandescent lamp consist of a durable aluminum case, have a built -in cartridge and heat -resistant shock -resistant borosilicate glass cap. The protective cap is attached to the case with a thread.

- LEDs - differ in special protection from blows and mechanical loads, voltage changes and adverse climatic effects. Since special requirements are imposed on such lighting devices, their design should be adapted to work in rooms with hazardous or harmful production. Also, LED explosion -proof lamps are used to illuminate buildings or for street lighting. This type is most common and is used not only in industrial enterprises, but also in offices, on the streets, etc. The price of LED explosion -proof lamps depends on the sphere of their use.

Separation by type of installation

And the last classification involves the separation of lighting models according to the type of installation. For example, there are suspended lamps that can be broadcast on a hook, ceiling or mounting pipe.

So, the following types of lamps are distinguished by the installation method:

- Suspended - the ability to install on a hook, ceiling or mounting pipe on special suspended structures. Used in warehouses and in large rooms with high ceilings.

- Wall - installed on a vertical surface, like indoor sconces.

- Portable - devices whose location can be changed if necessary. A portable explosion -proof lamp is used if the work is carried out far from the main light source.