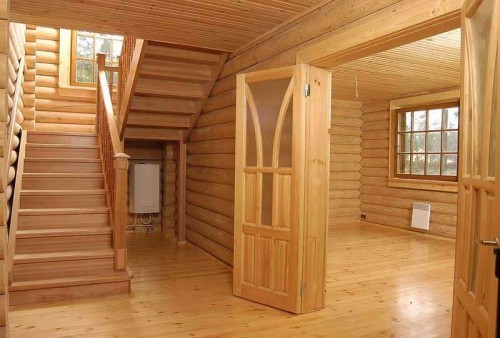

After the construction of a wooden house, the next step is to carry out work on its interior decoration. The quality of their implementation should be paid to special attention, since the comfort of the person’s stay, heat and sound insulation characteristics of the room, as well as the aesthetic attractiveness of the house, will depend on the quality of the work.

Content

Features of the decoration of a wooden log house

The need for interior decoration is due to the following reasons:

- as a result of finishing work, the house takes on a more attractive appearance;

- the lack of finishing significantly reduces the period of operation of the structure. In the presence of isolation on the main material from which the house was erected, is significantly less than the load, which as a result contributes to the safety of the structure;

- the finish improves the thermal insulation properties of the house, so the performance of these work will contribute not only to the creation of a comfortable temperature indoor, but will also significantly save money on heating.

The decoration of the log house cannot be proceeded immediately at the end of construction. It is necessary to wait for a certain period of time - from 1 to 1.5 years while there is a shrinkage of the house. Upon completion of this process, the construction will be ready for indoor work.

However, among the options for decoration, there is a method to reduce expectations and perform appropriate work after the completion of construction. This method consists in the processing of a polished log house with paint and vanicular products. This makes it possible to significantly save time. Performing the finish in this way is advisable if the log house is warm enough and there is no need for additional isolation, as well as in the presence of even walls.

The advantages of this process are as follows:

- there is an opportunity to start work immediately after building a house;

- simplicity of work;

- lack of significant expenses.

The disadvantages include:

- the inability to hide communication;

- complexity in the process of finishing an absolutely flat wall surface;

- the fragmentation of the coating.

Such a finish needs to be updated every 5 years. By this time, other materials can be used, since the shrinkage of the log house will be finally completed. Consider all the available materials with which you can finish.

Features of working with lining

This type of material is boards up to 220 mm thick, which are produced on the basis of deciduous and pine woods. Installation of the lining can be performed by a horizontal and vertical method. To determine the most suitable way to proceed from the size of the structure:

- For small houses, a suitable option will be a vertical styling.

- If the construction has large parameters in this case, it is better to dwell on horizontal installation. This condition is explained by the size of the material. The length of the lining is 2.5 m. With an inappropriate styling method, joints form.

The factors should also include the following factors:

- Before starting work, it is recommended to treat the lining with special drugs protecting the material from fire, as well as the negative effects of insects and moisture.

- The lining is recommended to be attached to the crate. Thus, laying will turn out as flat as possible, in addition, the communications can be hidden behind the crate frame. The presence of a crate is not mandatory if the house is built of glued or profiled timber, since such walls themselves are quite smooth.

- For crate, bars are used, which are located along the entire perimeter in a horizontal way, while observing a distance of 50 cm.

The interior decoration of the log house should start from the corner of the room. Thanks to the clutch of the “spike-paz”, styling will be done smoothly and will not require large labor costs. There are three methods for attaching boards to the docks:

- The highest quality method is considered to be fixed by means of a special clamp called Kleimer. One part of this product is fixed inside the groove, the second part must be connected by a self -tapping screw to the rail.

- The mount is also carried out using galvanized nails. Under the corresponding inclination of 45 °, the nail is inserted into the “groove” and clogged.

- The last third way involves the use of a sumoresis screw. In the board it is necessary to make a hole, the diameter of which should correspond to the screw hat, and the depth should be equal to half the thickness of the board. Then, screw the screws into this hole and closed with a font. After that, it is necessary to align the font with the board by grinding.

The use of the lining has both advantages and disadvantages. This material is characterized by ease of installation, environmental safety, creates additional insulation and has a natural appearance. But at the same time, the lining is quite expensive and the boards before work should be treated with special drugs.

Front finish. Photo:

Rules for the finish using rope

This option can be used only for a log house erected from a rounded log. The presented decoration method is performed using a jute decorative rope and requires compliance with some rules:

- You should start work only after processing the beam with antiseptic agents.

- The rope is laid in the crowns of the structure. Such a decoration helps to keep the heat indoors, and also prevents the intake of the structure of wind and moisture inside.

- The rope is attached in several ways:

- through brackets;

- with glue;

- due to special nails.

The process of internal cladding occurs in the following sequence of actions:

- Before installation, the rope should be treated with an antiseptic drug. Next, you need to cut off a fragment of the required length.

- The edges should be wrapped with threads and treated with varnish or glue in order to avoid their dissolution.

- For fastening, a special thermal glue is used, which is applied using a pistol. Glue should be applied to the bars in the places of fastening of the rope.

- After you need to lay the rope on the glue.

- In parallel, it is necessary to drive small nails into it - 15 cm - 20 cm.

- After the work is completed, the rope and logs need to be covered with varnish.

The rope has such advantages as:

- acceptable cost;

- reliable protection of the seams of the log house from the penetration of the cold;

- originality and decorativeness.

However, the disadvantages of this material are the following factors:

- labor -intensive installation process;

- the inability to hide communication;

- difficulties in warming with other materials.

Features of the application of the House block

The installation of this material is similar to laying the lining and involves the following sequence of actions:

- The decoration of the log house inside is carried out on the dozen frame.

- You need to start work from below and move in the upper direction.

- The last board will need to be cut, in the upper part of the wall it will be less striking.

- It is worth noting that the House block is laid exclusively with a horizontal way.

The advantages of this material are features such as:

- reliable imitation of this hut;

- simplicity of laying;

- the ability to insulate the walls and hide communications.

The disadvantages of the House block include:

- high cost;

- unnatural appearance with improper styling.

Method of finishing by putty

Despite the fact that this option is used in most cases for walls made of brick, this method can also be used for decoration of buildings from a log house. In this case, the plaster composition on a mineral or acrylic basis should be used. The putty creates a coating that protects the log house from exposure to destructive factors. Also, using special components, the composition can be given the desired color.

The decoration process is simplicity: first, by means of screws, you need to attach a net to the log house, and plaster should be applied to it. This method makes it possible to align the surface of the walls.

The obvious advantages of putty are low cost, a large selection of colors. The process of applying the composition does not require special skills and knowledge, non -professional, in the shortest possible time, may well cope with work. But such a decoration will not last relatively for long - about 5 years. Also, it will not be possible to completely hide the pipes, and the decoration in general will not have a pronounced aesthetic species.

The use of drywall

This material is quite rare as a trim for a log house, since in this case a characteristic impression of a wooden house disappears. But in some cases, this move justifies itself. The cladding process has the following features:

- Gypsum cardboard is mounted on a crate made in the form of a P-shaped profile.

- Between the log house and drywall, it is recommended to lay the insulation, for example, glass wool.

- Then the material is attached to the profile by means of screws.

- After completing the installation work, the joints must be subsided, this will provide an even surface.

As the advantages of drywall material, the following factors can be distinguished:

- the possibility of fulfilling the recesses and protrusions in the wall. This will make it possible to hide pipes and wires and embody any design solutions;

- this material is also characterized by low cost and ease of installation process.

Among the shortcomings, comparative fragility should be distinguished, because The material will last from 15 to 20 years. In addition, the need to use additional insulation materials, instability to damage and eliminating a characteristic atmosphere inherent in wood houses.

Plastic trim

This material is suitable for the decoration of individual zones of the log house, however, not for its full cladding. Plastic is mounted horizontal and vertical. The last option is the most common:

- At the initial stage of the work, you need to assemble the frame. Panel products will be attached to it.

- In the upper and lower part of the frame it is necessary to attach profiles.

- Installation should start from the corner. The panel should first be brought into the profile, after which the clutch occurs.

- The panels are attached to the profile using self -tapping screws and nails. To improve the connection of plastic panels, liquid nails or glue are used.

The advantage of plastic as finishing material is the following features:

- ease of installation;

- affordable cost;

- the ability to hide communications;

- sufficient choice of color gama.

But at the same time, the plastic material also has disadvantages:

- mild ignorance;

- insufficient resistance to mechanical influences.

Conclusion

The interior decoration is essential for the subsequent operation of the log house. First of all, with the help of finishing materials, you can solve aesthetic problems and arrange a house in accordance with your preferences. In addition, the decoration is also of practical importance for the log house. It will create an additional insulation layer and will contribute to maintaining a comfortable temperature in the room.

Interior decoration of the log house. Video: