Often the bathroom is the only cold room in the apartment. The causes of an uncomfortable microclimate can be very different. It can be the wall of the bathroom that goes outside or into a technical room that does not work a coil of a heated towel rail, problems with ventilation ducts, etc.

Content

- The choice of material for insulation of the bathroom from the inside

- Materials and tools for internal bathroom insulation

- Preparation of the premises for the installation of insulation

- Installation of polystyrene insulation inside the bathroom

- The final stage of the bathroom insulation from the inside

There is not always a real opportunity to produce external insulation. For example, behind the wall there is a deformation seam, an elevator shaft, entrance or other unheated room in which it is impossible to mount insulation. It is not difficult to do internal wall insulation in the bathroom.

The choice of material for insulation of the bathroom from the inside

The insulation material for the bathroom should have low heat production, not absorb moisture, be durable and durable. Mineral wool, due to its peculiarity, absorb moisture, is not suitable for insulation of the bathroom.

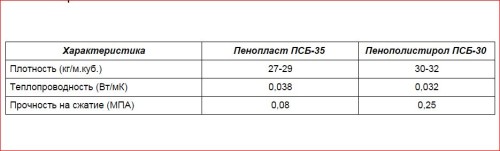

- The easiest and cheaper to insulate the internal walls with foam and with your own hands. Foam is inexpensive and practical material. A low price, lightness in processing and low heat -conductivity favorably secrete it among similar types of insulation material. Foam has an extremely low vapor permeability coefficient. He does not pass steam, but does not absorb it and is suitable for insulation of any type of walls. When choosing the material for insulation of the walls inside the bathroom, keep in mind that its price depends on the density and thickness of the insulation.

- You can insulate the internal walls and polystyrene foam. Extruded polystyrene foam has similar properties. The high density of polystyrene foam allows you to maintain high thermal insulation properties with less thickness. This is of great importance when warming a small bathroom. In addition, it is stronger, and the methods of its installation are no different from insulation with foam.

The process of insulation of internal walls with a foam with your own hands is on the video at the end of the article.

Materials and tools for internal bathroom insulation

Measure the area of \u200b\u200beach wall separately. On a sheet of paper, draw a bathroom circuit in a detailed form. According to the scheme, the required number of sheets of insulation is calculated. Foam and polystyrene foam are produced in sheets of 1x1 and 1x0.5 m. In the drawing, consider the procedure for laying insulation with a minimum number of joints and waste.

- In the event that the interior decoration is planned from drywall, it is necessary to take into account the tolerances on the crate from the galvanized profile, which is attached to the walls of the bathroom before the installation of the insulation. In this case, it is economical to take a step of profile planks 1x0.5 meters, and the insulation purchase the corresponding size and thickness.

- To arrange the crate, purchase a rack profile (PS) or (CW) and the guide profile (PN) or (UW). The standard profile depth is 40 mm, and 50 mm is enough in width for the bathroom.

You will need glue for foam, glue consumption in accordance with the area is indicated on the package. Plastic dowels, reinforcing plastic grid, primer and putty.

Tool:

- A turbocharging machine and a drill with a mixer.

- A hammer, a chisel, a roulette and a mounting knife.

- Spatula 50 and 200 mm and one gear for glue.

Preparation of the premises for the installation of insulation

Before starting work, it is necessary to dismantle all removable items in the bathroom. Bath, shower, shell, cabinets, etc. For internal wiring pipes and sewage, it is best to build a gypsum plasterboard box or moisture -resistant OSB.

- The walls are cleaned of paint, whitewashing or ceramic tiles and are aligned. The paint and whitewash are removed with a spatula and a brush with a metal bristle, and then the walls are washed with a soap solution and water. The tile is knocked down by a chisel and a hammer. The remnants of the glue are trimmed with a turbocharging machine. Pits and hollows are covered with glue for insulation or cement mortar. The surface of the walls should be even and hygroscopic.

- For the installation of foam, followed by gypsum plasters, a valve crate is mounted. In order to avoid the occurrence of cold bridges, empty profile openings should be filled with foam strips. The profile is attached to the walls with dowels in such a way that vertical cells are formed 1x0.5 meters.

The surfaces inside the cells are treated with deeply penetrating primer and antiseptic drugs.

Installation of polystyrene insulation inside the bathroom

- Take a bucket and fill it to half with a dry adhesive mixture for foam. Having added a little water, mix the mixture with a spatula, and then a drill with a mixer. Alternately adding water or dry glue, get the consistency of dense cream. The adhesive mixture should not slide from a spatula or foam.

- On a sheet of foam 1x0.5 meters, 16 - 18 strokes of glue are applied. Smopes are evenly distributed along the plane of a foam sheet and trimmed with a gear spatula.

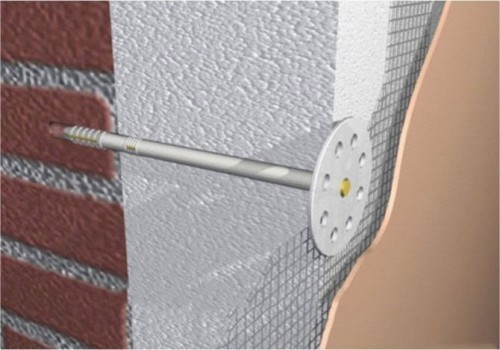

- The foam sheet is installed in the cell, tightly pressed against the wall and is knocked out by the palm over the entire plane. In the middle of the sheet in the upper and lower quarters, plastic dowels are installed for fixing the foam. The holes are drilled through the foam along the diameter of the dowel.

- The tip of the dowel is broken down with an mounting knife along the factory mark and inserted into the hole until the stop. The fixing plastic nail is inserted into the dowel hole and clogged with a hammer. Nothing terrible will happen if during the installation process the dowel hat is deepened into the foam of 3 - 4 mm. This place is simply covered with glue for insulation.

- After the installation of entire sheets, measure and cut the remaining incomplete places. All four sides are measured roulette. Using a ruler or flat rail, the sizes are transferred to a foam sheet. The blanks are cut out with an mounting knife and installed in their cells in the method described above.

The final stage of the bathroom insulation from the inside

When decorating insulated walls with drywall, sheets are screwed with self -tapping screws to the crate, treated with deep penetrating primers and put up. Gypsum cardboard can be covered with ceramic tiles or painted with water -based paint.

The insulated walls of the bathroom without installing the frame under the drywall are plastered and putty. During the plaster, a reinforcing mesh is used to give strength, and after putting the walls are treated with a soil mixture for waterproofing and an antiseptic.