Venetian plaster is a special finishing material for the decor of the surfaces of the walls, columns, partitions, etc., giving them a specific and spectacular look. In addition, the plane, thus processed, has unique physical and technical properties.

Venetian plaster on your own? Our master class will make this idea a reality. But, for starters, a little theory.

What is Venetian decorative plaster?

This type of building material is used to finish wall structures and obtained from the waste processing waste of various breeds of natural stone.

Such a special bases can be obtained from:

- Granite.

- Marble.

- Quartz, etc.

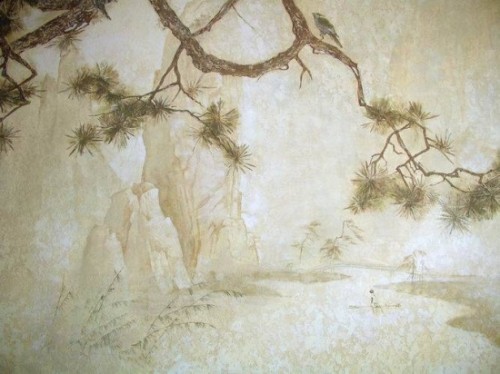

What does the interior look like using Venetian plaster, will clearly demonstrate the photo:

Compound

The proportions of the compositions, the sizes of stone particles and complementary components can vary, but the basic components of modern Venetian plaster are unchanged:

- Baby made of stone raw materials. The smaller the diameter of the stone particles, the better the material lies, and the easier it is to apply it.

- Binder. Initially, gashnee lime was used as such a component. Today is acrylic.

- Coloring component. Mineral -based natural dyes are considered an ideal option. However, today they were almost replaced by artificial analogues. Dyes should be introduced into the suspension shortly before application.

- Water.

Consistency

After mixing all the components, a cream -shaped substance should form.

What surface can be finished with Venetian plaster?

- Concrete.

- Wooden.

- Brick.

But, definitely, this surface should be clean, even and smooth.

The properties that stand out the Venetian plaster for wall decoration

- Transparency.

- Moisture resistance.

- Strength.

- Air permeability.

"Pros"

- A stunning visual effect imitating natural textures.

- Durability (service life is approximately 15 years).

- A hard breathing protective layer is not destroyed under the influence of moisture.

- The ability to create a decor of any color and texture, taking into account your personal tastes and preferences.

- Environmental friendliness and fire safety.

- The possibility of restoration of the coating.

"Cons"

- The need for a particularly thorough preparation of the plane for the decoration (due to the transparent texture of the created coating).

- The complexity of the application.

- High cost.

True, if you still decide to apply Venetian plaster yourself, then the cost of decoration will be reduced at times.

Venetian plaster technology

This process, of course, is not for complete profiles in the field of construction and decoration. The presence of elementary knowledge, imagination and basic skills is welcome. In order not to start fulfilling the task blindly, we offer to view the selection of videos on the topic “Venetian plaster. Video lessons for application ":

What needs to be prepared by starting work?

- Wide spatula (200 mm).

- Narrow spatula (60 mm).

- Trowel.

- Sponge or suede fabric.

- Dishes for mixing components.

- Vetosh.

- Construction mixer or drill.

- Eskaric paper or grinding machine.

- Stone baby.

- Binder.

- Color.

- Putty.

- A primer with quartz filler.

- Wax.

Nuance! The edges of the spatula must be rounded and thoroughly polished so as not to create unnecessary defects on the decorated surface.

Preliminary processing of the plane of the wall before applying the plaster

This stage for this decoration technology is very significant, because The layer of the coating of a small thickness and any failed defects will be visible. Therefore, you are treated with all responsibility.

- Clean the surface of garbage and the remains of the previous coating.

- Inspect it for possible cracks and chips.

- Bend all defects and bumps.

- Let it dry.

- Pull out, leveling and smoothing the surface.

- Grind. You can add to the primer the color that you are going to enter into decorative plaster later.

Creating a decorative mixture

- Mix all components (crumbs, binder and dye).

- Pour water slowly with a thin stream, mixing all the time to the consistency of sour cream.

- You can experiment with proportions using small volumes of materials. By the way, the process of application itself is also better to rehearse on a small plank.

Another option:

- Buy a ready -made dry mixture.

- Dilute it with water.

- Stir well by wielding a construction mixer.

- Let it brew for a while.

- Mix again.

- Enter the dye, stirring.

Nuance! To create a more homogeneous mass, use water, not colder than 10 ° C.

Application process

- Apply plaster with several thin layers about 3 mm thick.

- After creating each layer, thoroughly dry it and grind it.

- The first layer is the main one, which sets the tone for the entire coating, the rest of the layers are decorative.

Final processing

Using Venetian plaster, you can get a glossy surface or matte. In the first case, to achieve the desired visual effect, wax processing is used, in the second - smoothing the applied material with a special spatula. As a result of friction under the influence of heat, a strong polymer crust is formed.

There are many different ways to apply Venetian plaster. The final result will depend on what you choose. Describing this process is in vain. This is exactly the case when it is better to see than to hear a hundred times. Look for videos on the network, watch and learn! And remember, you will succeed!