If you want to turn the balcony into a cozy recreation area, where you can spend time in summer and winter, you should think not only about the interior decoration of the walls, but also about the insulation of the floor. In this article, we will tell you how to properly insulate the floor on the balcony and what materials can be used for this.

Content

Types of materials for thermal insulation of the floor

If you do not know how it is better to insulate the floor on the balcony, we suggest that you consider several types of materials that are well suited for such a purpose.

Foamed polyethylene

The insulation, created on the basis of foamed polyethylene, is often presented on sale in the form of rolls. The thickness of the sheets is several millimeters, and the thermal insulation properties of such a material are not the highest, which is why it is used in combination with other means.

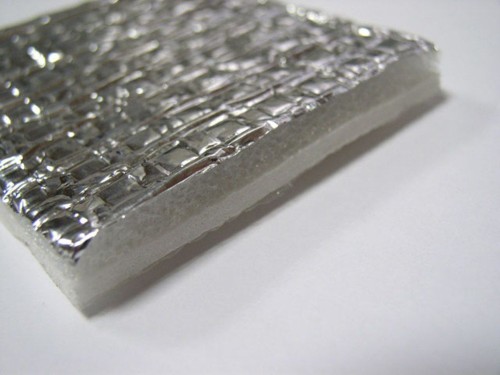

One of the popular heater based on foamed polyethylene is a foam, one side of which is covered with foil. Rolls should be laid so that the reflecting layer is at the top - so there will be more heat in the room. In addition to thermal insulating properties, Penophol also has water -repellent qualities. Its minus is that it has poor vapor permeability.

On the sale of Penofol is represented by three main types:

- penophol “A” has a reflective coating on one side of the sheet;

- penophol "B" is characterized in that it is covered with foil on both sides;

- penophol “C” on one side is covered with foil, and a protective substrate is glued to its second side.

Foam polystyrene

For insulation of flooring in rooms, polystyrene foam is often used. It has a number of advantages, the main of which are considered small weight, good heat -insulating ability, ease of installation, as well as low cost. Polistyle foam is available in price and is sold in almost any construction store.

One of the varieties of polystyrene foam is a foam - foamed material with low thermal conductivity, high density, good water -repellent properties and a small mass. This type of insulation has excellent operational characteristics and a long service life, but before insulation of the floor on the balcony with a foam, it will not hurt to familiarize yourself with its shortcomings:

- the material has poor vapor permeability;

- low -quality polystyrene foam emits toxic substances into the external environment, the same applies to the combustion process;

- many foam stamps do not differ in high strength.

Mineral wool

Many consider mineral wool the most acceptable option for insulation of residential premises. Firstly, its thermal insulation qualities are on top, and secondly, it is completely safe in terms of combustion, environmentally friendly and harmless. Mineral wool is easy to work, its light weight and elasticity allow you to easily warm any spaces and even the most inaccessible places.

The disadvantages of the material include that it must be mounted in overalls, goggles, respirator and gloves. Vata fibers are easily crumble and can damage the skin, mucous membranes, eyes. Among other things, low -quality cheap wool is made with the addition of formaldehyde, and it is very dangerous to health.

Before insulation of the floor on the balcony with this material, you should get acquainted with its varieties:

- There is mineral wool, which is made of domain slag, but it is practically not used to warm up residential buildings and premises.

- Glass wort is another subspecies of mineral wool. It is environmentally friendly, light, but its fibers are too brittle. This means that it is necessary to work with her, observing caution, and the outer layers of the insulation cake should completely protect the room from the glass of glass microcress entering it.

- Basalt cotton wool is the best option for insulation for residential premises. It is more expensive than glass wools, but in its operational characteristics it exceeds the previous analogue.

Ceramzit

Expanded clay is used to warm the balcony floor not so terrible, since it has worst thermo -insulating properties than a foam, foam or mineral wool. Nevertheless, this material is distinguished by environmental purity and non -combustibility. Expanded clay is relatively light in weight, although heavier than the above analogues.

Before insulation of the floor on the balcony by expanded clay, you should choose the appropriate option. This material differs in fractions. The smallest elements are from 0.1 to 5 mm, there are larger fractions, which reach a length of 4-5 cm. In some cases, expanded clay is interfered in a concrete solution and applied to the floor with a layer of screed, and sometimes arranged on the floor, space Between which they fall asleep with insulation.

If you do not know how to insulate the floor on the balcony under the screed, think about the option of using expanded clay. Today, the so -called “dry screed” technology becomes more popular. In the process of its execution, the floor is first covered with a layer of fine -fractional expanded clay, on top of which plate of gypsum fiber is laid.

Floor preparation work for insulation

Before the direct process of thermal insulation of the balcony floor, its surface must be prepared. This includes the following actions:

- The working base is aligned. The protrusions are cut or cut, the cracks are covered with a solution. Before embarrassing the cracks, the surface is thoroughly cleaned of debris and dust.

- Then the floor is covered with a deep penetration with a primer, after which they begin to light the problem areas.

- To close the cracks is the most qualitatively and reliable, it is recommended to expand them to a depth of 10 mm, and then fill in the suitable repair composition. As such a composition, concrete solution, putty, sealants are used.

- After solidifying the product, its excess is cut off and polished the surface to one level.

Before insulated the floor on the balcony under the tile or other finish, it must be waterproofed. Sometimes for waterproofing it will be enough to simply cover the base with a layer of primer, but in some cases it is worth performing more complex work. With poor waterproofing, moisture can fall into the insulation layer, which, sometimes, is detrimental to the material.

The waterproofing of the floor on the balcony can be carried out by several methods:

- Apply a layer of penetrating material to the working base, for example, hydrotect e or “penetron”. This method can be used for concrete floor.

- Cover the floor with a layer of coating waterproofing made on bitumen or on a polymer basis.

- Install a layer of gluing roll insulation on the floor. At the same time, it is important to make sure that the sheets of the material are very tight and adjacent to the surface throughout the area.

Floor insulation using P-shaped racks

One of the simple ways of insulation of the floor on the balcony with your own hands is to create a frame from the P-shaped racks-kronsteins. Under such a frame, an additional space remains where you can lay a layer of heat -insulating material. We describe the process in the form of a sequence of actions:

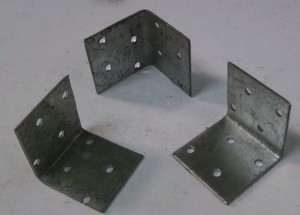

- First you need to calculate the right number of racks. They are installed every 50 cm on each longitudinal lag, as well as 1 piece on all transverse jumpers. On the balcony, as a rule, 3 longitudinal lags are enough. Rumors are based on the P-shaped racks and attached to the lags of metal corners. When installing jumpers, it is important to consider the location of the joints of the plywood, which will become the upper layer of the insulation cake. It is advisable to draw on paper the location of all elements on paper before the installation.

- Before starting the installation of the frame, the floor must be cleaned of garbage. Then, markings are applied to the working base by the marker. Noting the location of the lag, it is worth taking into account that the bars are mounted not close to the wall, but with a gap of 5 cm. The “zero line” should also be noted on the wall using the building level.

- Having inflicted the line of the future position of the lag, you can also indicate the installation sites of the jumpers. At those points where the brackets will be attached, you also need to apply the appropriate markers. If you do not mount whole lags, but join individual fragments of bars, then in the places of their connection you must definitely put at the P-shaped rack.

- Through the holes in the brackets on the floor, you should outline the location of the dowels. Subsequently, holes under the fasteners are drilled there.

- Then, when the holes are made, the P-shaped racks are fixed on the floor. Without twisting the dowels to the end, check the evenness of the location of the elements. If everything is in order, the dowels are screwed to the stop.

- Installation of the insulation and installation of the lag must be carried out simultaneously so that there are no gaps and pockets left anywhere, through which the cold will penetrate the room. In the process of creating the frame, the insulation should be cut into elements suitable in size. In these details they make slots where vertical brackets will enter. After that, the insulation is mounted on the balcony floor, putting on the sheets on the racks.

- Between the halves of the P-shaped rack, a wooden lag is inserted, its equal along the “zero line” marked on the wall. The beam is fixed slightly using only 1 fasteners. After that, the lag is aligned from the opposite side. The construction level is checked by the accuracy of installation, after which the beam is finally fixed with self -tapping screws.

- At the opposite wall of the rack, insulation and lags are fixed in a similar way. In the process, it is important to check so that all the bars are in the same horizontal plane.

- The third longitudinal part of the frame is laid in the middle between two extreme ones. The work is carried out in the same way: first, the P-shaped brackets are attached to the floor, a strip of insulation is put on them, and a wooden beam is mounted on top. The level of lags is checked by two extreme rails.

- In order for the frame to be strong and stable, between the longitudinal lags, it is necessary to lay the crossbars. They are attached to the same P-shaped racks that are installed one in the middle between the lags. As in previous cases, a heater is first put on the brackets, and then a wooden beam is screwed.

- The jumper is cut off such a length that it is freely placed between the longitudinal lags. When installing it, it is not attached to the beams immediately, but only after a thorough check of the level.

- When all the lags and crossbars are mounted, the frame can be considered ready. At this stage, you can proceed to the final insulation of the balcony floor.

- Between the parts of the frame there were incomplete zones. To lay a heater there, you need to cut out fragments of a suitable size. They are installed in the “windows”, and then the second layer of the heat -insulating material is mounted, which should be located flush with the lags.

- The last layer of insulation cake will be plywood. Parts of the required size are cut from it, which are subsequently laid on a wooden frame and fixed with self -tapping screws. A gap of several millimeters is necessarily left between the plywood and the walls, which will compensate for the linear expansion of materials under the influence of temperatures.

- Under the plywood you can lay a vapor -permeable membrane, and only then mount the sheets. Self -tapping screws in the plywood need to be twisted very tightly, literally scoring them into the wood.

- The finished floor can be finished in any convenient way.

Floor insulation with a heating system

On the balcony, you can make the so -called “warm floor”, walking along which will be comfortable even in the coldest weather. This option is especially successful if you decide to use tiles as a decorative decoration. You can learn in detail about how to properly insulate the floor on the balcony, from the video on the Internet, we would like to give a description of this process:

- First, on the floor, it is necessary to mount the frame. To do this, crosses on the floor, on top of which three longitudinal lags are installed. The crosses are cut such a length that they are freely placed between the wall of the house and the outer wall of the balcony, and at the same time there are gaps of 5 cm on each side.

- The transverse supports are mounted at a distance of 50 cm from each other.

- Lags are laid on top of the transverse beams. Two at each wall and one in the middle. As in the previous case, the lags should be located at a distance of 5 cm from the wall. The bars are attached to the crossbars with the help of self -tapping screws.

- After that, openings are drilled through the lower crossbars in the floor, where the spacer questionnaires are inserted. Beams are fixed with anchor mounts on both sides.

- On the assembled frame you can mount a heater. In this case, the foam will be the heater. Parts of the desired size are cut out of it and laid between the lags on top of the crossbars. The foam can do not fit the frame too tightly, the presence of gaps up to 7 mm is allowed.

- When the insulation is fully installed, the formed gaps should be filled with mounting foam and wait for its solidification. After that, the excess must be cut off.

- Plywood sheets are laid on top of the foam, after cutting out fragments of the desired size. They are attached to wood with self -tapping screws, which are screwed in a step of 15 cm and recovered into sheets to a depth of 1 mm.

- On the finished plywood coating, you can lay the infrared "warm floor" system. To do this, at first, a layer of foam is laid on the working base, placing it with a foil side up. At the edges of the foam are glued to a bilateral tape, the same is done with the joints of the sheets.

- Infrared film heaters are laid on top of the substrate. Like Penophol, they are fixed on the edges with bilateral tape. If several segments of the material are used, it is forbidden to apply them on each other.

- After that, the free ends of the wires are isolated, all conductive tires are connected to the thermal attachment, then, according to the scheme, the cable part is swept. The wires are switched on the terminals of the block, which is placed in a place convenient for use.

- Upon completion of all work, the floor is checked for performance. If everything is in order, the power is disconnected and the installation of the finish coating continues. To begin with, infrared wires are covered with film waterproofing in order to protect them from accidental water. The film in all places should ensure complete tightness. Fragments are overlapping, all seams are glued with waterproof tape.

- The next step in insulation of the balcony with warm floors is the laying of decorative finishing material. Trying not to damage the film, a finish layer, for example, laminate, is mounted on top of it.

- The final step will be the installation of the skirting board after the walls of the balcony.