Since ancient times, wooden houses and buildings from a log log have had special value. They are beautiful and durable, and most importantly - absolutely safe for the environment. Recently, more and more often the owners of cottages have been chosen for the construction of country houses.

Content

Most of us dreams of resting far from the bustle of the city not only in the summer, but also in the cold season. It is unlikely that it will be possible to relax in a wooden house in winter, because in such houses there is no centralized heating. That is why insulation of the walls of a wooden house is considered very relevant.

Many believe that if the house is built of natural wood, then it should not be insulated. On the contrary, it, like brick, requires wall insulation, because wood cannot provide a good level of thermal protection.

When warming the walls outside the wooden house, the hosts will receive a maximum of comfort. And if the house is protected by temperature changes, then its operational period will be much higher.

With a positive solution to warming the house, many people have questions - starting with what kind of insulation to give preference, which materials to choose and how to do the work on the insulation of a wooden house.

On the advantages and disadvantages of insulation

Often, when it is about warming wooden residential buildings, experts advise to warm the house outside.

This is due to a number of reasons:

- the internal area of \u200b\u200bthe house does not decrease;

- a wooden beam is protected from the effects of atmospheric precipitation, as well as from temperature changes;

- through a layer of insulating material, moisture can circulate freely and go out;

- inside the house, a unique aroma and texture of natural building material will remain.

Of the shortcomings of insulation of the internal walls of wooden houses, experts note the following:

- the area of \u200b\u200bthe premises inside the house becomes smaller;

- between the insulation and the wooden wall in cool times, condensate often accumulates;

- if the insulation is located incorrectly, then the wall will be in a cold atmosphere - which means that later it will begin to crack, and the tree will split.

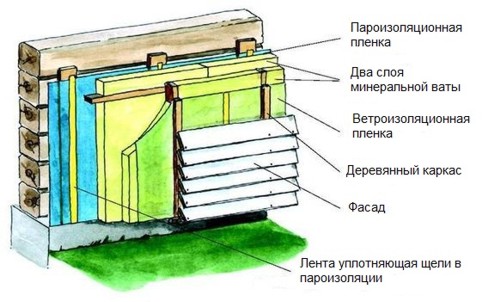

In addition, it is necessary to insulate wooden houses according to a certain technology. So, insulating materials should be located according to this principle - "display moisture from the inside - outside." Therefore, the first layer of insulation should be vapor barrier so that a stream of wet air does not fall into the room.

After laying the first layer, the second one should be installed - thermal insulation. It will help maintain warm air inside the house. The third layer - waterproofing, will allow you to hold moisture and will pass steam.

Insulation from the inside or outside?

Before starting work, it is necessary to decide how to insulate the house - from the inside or outside. It is recommended that insulation of the walls of a wooden house from the inside are performed if the owner of a wooden house does not want the walls to lose his natural appearance. But with this method, it is necessary to remember that the main wall that is located under the insulation will remain in the low temperature zone. At the same time, it is highly likely that condensate will appear between the heater and the wall, which can contribute to the propagation of molds.

In addition, it is worth paying attention to how the wooden beam is laid indoors. If round floors do not closely adjoin the wall, then in these places it is impossible to install insulation. The language of builders is called this term as "cold bridges." In these places, heat will be lost very quickly, and heat loss coefficient often exceeds heat indicators along the entire perimeter of the wall.

With external insulation of a wooden house, you can get a uniform distribution of temperature over the area of \u200b\u200bthe entire wall. The selection of thermal insulation materials affects the temperature regime and moisture accumulation. So, dense materials will not let water steam in the room. Light and porous must be installed outside. If the wall is insulated outside and high -quality materials, then this will obtain high thermal insulation properties.

Types of insulation

Popular types of heater of wooden houses:

- Mineral wool.

- Ecowata.

- Foam.

- Penophol.

Minvata is light, fast and relatively inexpensive insulation.

Advantages of mineral wool:

- does not burn;

- well "holds" heat;

- soft;

- elastic;

- just lay;

- it withstands large temperature changes.

For insulation of wooden houses outside, owners often use mineral wool. It is produced in several versions: mats, plates and rolls.

This material fills all the voids well. First, a frame is formed, which is filled with roll wool. Additionally, it is not necessary to fix the mineral wool to the carrier, it will hold well.

On top of the insulation you can lay a new board and, if desired, perform the lining of the house with siding.

Ecowata consists of antiseptic and natural fiber - cellulose. She successfully withstands the test of severe frosts and strong winds.

Among the advantages of this insulation are noted:

- environmental friendliness;

- prevents mold;

- this material will not bite mice and other rodents;

- used to warm the room outside;

- the wall under the insulation "breathes";

- the material does not burn, but only smolders, while it does not emit toxins.

The internal walls of the houses are sheathed with foam. Specialists do not recommend warming wooden walls outside the house with this material, because the foam does not pass air. Therefore, when warming the walls inside a wooden house, condensate, mold mushrooms may appear, and the tree will be rotted. When warming the walls of a wooden house with a foam, a frame is first installed from the rails to provide an air gap, and then foam plates are fixed (the thickness of one slab is five centimeters) using special solutions or fasteners.

Ways of wall insulation

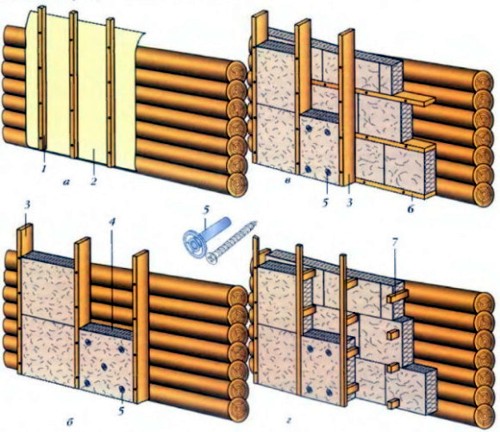

In this photo you can see the order of insulation of the walls of the house outside:

The sequence of work is as follows:

- Vapor barrier. This layer will provide ventilation under the film. If the facade of the house is composed of a round log, then you can fix the material immediately on a tree, but at the same time large gaps will form. If the surface is smooth, then the rails are nailed (the thickness of a wooden rail - two and a half centimeters). The distance between each rail should be about one meter. For vapor barrier, it is necessary to prepare roofing material, foil and special film. Materials are attached to wooden rails, providing holes at the top and bottom for free air flow. The diameter of the holes is two centimeters. Attention! In places of fastening of nails or brackets, additional sealing is necessary.

- For the arrangement of a wooden frame, a wooden board ten centimeters wide and a thickness of not more than five centimeters is used. The boards should be beaten vertically at a distance of one or two centimeters from each other. So you can prevent the formation of voids and cracks.

- Laying the heat -insulating layer. If you have chosen an ecovat as a heater, then an additional use of a blowing machine is necessary, which will allow the material to the wall with an even layer. Remember that in this case, laying a vapor barrier film will not be needed. When using plates, they should be tightly laid in a wooden frame. To achieve this, you should choose semi -rigid plates, the density of which is one hundred twenty kilograms per cubic meter. To ensure the density of the fit of the material, it is necessary to lay the plates in the "chess" order.

- Laying a waterproofing layer. To do this, it is necessary to purchase a steam -permeable film that will pass steam, but at the same time prevent it from getting it on the insulation. The film is installed in the same way as installing a vapor barrier layer. After the work is completed, the boards should be installed, which will make it possible to evaporate the condensate that falls on the waterproofing layer. In this case, you can use wooden rails with a thickness of two to three centimeters, five centimeters wide.

In order to provide additional protection against insects and rodents, it is necessary to install a fine -mesh metal mesh. And in the case of laying mineral wool, this condition should be fulfilled.

After performing work on external insulation of a wooden house, you should decide on the outer skin. You can pour wooden boards, a lining of pine or oak on top. In this case, natural building materials must be treated and opened with varnish.

Interventive insulation method of the house

Intervented insulation improves thermal insulation of the house, protects against damage, and also extends the life of a wooden house. A distinctive feature of this type of insulation is that it must be laid between wooden bars during the construction of a new house.

For insulation, strip insulation is used. It consists of natural material - flax that goes well with a tree, and at low temperatures does not lose its properties.

Among the advantages of this type of insulation is the fact that natural material is able to fill in the uneven logs. If the voids are large, then in this case you can put two layers of insulation. You can also fill in the gaps that appear when installing windows and doors.

Advantages of the material:

- has soundproofing properties;

- resistant to moisture;

- does not rot;

- it does not form mold;

- elastic;

- it has high strength.

Among the shortcomings, the high cost of insulation was noted. In addition, if the house is located in an area with a harsh climate, in this case one natural insulation will not be enough and it is necessary to additionally insulate the internal walls with foam or foam.

Warming of the walls of a wooden house with a foam

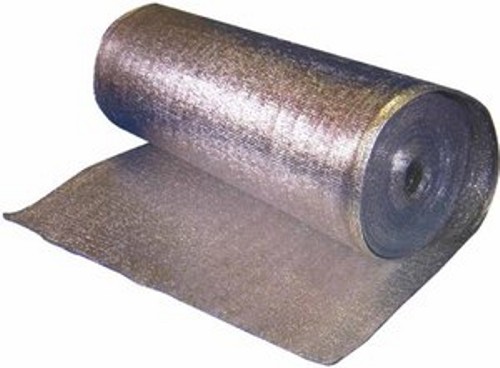

Penophol is a multilayer material that refers to the reflective insulation class. It consists of polished foil (up to ninety -seven percent of reflection) and foundations. The base can be of different densities and structures.

The thickness of the standard material can vary from two to ten millimeters. In harsh climatic conditions, it is necessary to use foam 40 mm thick.

The principle of operation of the insulation is similar to the work of the thermos. In winter, it will be warm in it, and in the summer it will be cool. Moreover, the material will not delay the heat located indoors, but will reflect it.

Advantages of insulation:

- environmentally friendly material;

- the material is thin, so additional space will not climb when warming the walls from the inside;

- no additional laying of vapor barrier materials is required;

- does not absorb moisture;

- has noise -insulating properties;

- conveniently transported;

- "Not interesting" to rodents;

- it has certification - the conclusion of the sanitary and epidemiological station.

Of the shortcomings, experts note the softness of the material, so it cannot be laid under plaster or attached to wallpaper. It is very difficult to fix the usual foam (exception - material with a self -adhesive film) directly to the wall itself.

The material is attached to the wooden frame using a furniture stapler. If the sheets are laid, then you can get the opposite effect and additional accumulation of steam on the walls of the room.

When laying the insulation outside the wooden house, it is necessary to prepare an air cushion consisting of a wooden frame and a metal. After laying the foam to the surface, you should perform the cladding of the building with siding or other suitable material.

How to make insulation of the walls of a wooden house, watch this video: