A flat roof is an inexpensive and practical way to arrange any structure. Often it is erected over multi -storey residential buildings, industrial facilities, garages and extensions (verandas, terraces). In the case of residential buildings, a flat roof must be insulated, otherwise the sense of it will be slightly. This is what we talk about in today's article - with our own hands, insulation of a flat roof.

Content

Features of insulation

The need to warm the roof, including flat, is obvious - any person who is familiar with the concept of convection from the school course of physics must understand that the air, heated, rushes upward. If at the top he does not meet a worthy obstacle, he will freely leave the room. In other words, all efforts to warm the house under a flat roof will come to naught.

However, the beneficial aspects of the roof insulation do not end there. In addition to the fact that thermal insulation retains warm air, it prevents the occurrence of sharp temperature differences inside the roof pie. Let us turn all the same school physics course. When cold street air encounters heated streams rising from the house, the reaction gives rise to condensate - the smallest droplets of water. When accumulating, condensate impregnates layers of a roof pie and wooden elements, provoking their rapid wear. For this reason, laying only insulation under the roof lining can not do - it is necessary to protect it with a vapor barrier membrane, which will remove condensate from thermal insulation and contribute to its rapid evaporation.

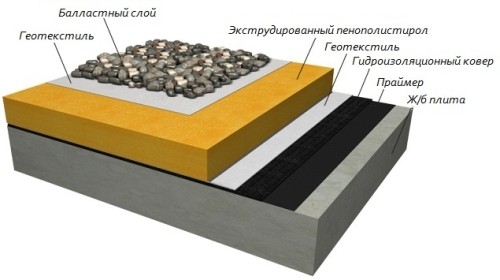

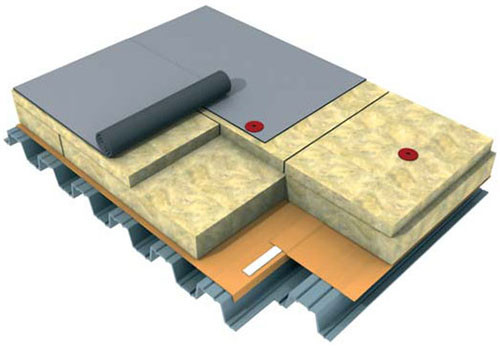

It turns out that the device of insulation of a flat roof involves the use of not only thermal insulation material, but also vapor barrier. The sequence of styling depends on the type of roof. Flat roofs are classic and inversion. In the first case, the supporting plate is based on, on which vapor barrier is laid, and then insulation. It, in turn, is closed with roll waterproofing based on bitumen. It simultaneously protects the insulation from moisture and is a finish coating. Such roofs can be found on multi -storey buildings in any city. It is also worth mentioning that the classic roof can be operated and unexplosive. As the name implies, the operated roof can be used, that is, to have equipment, furniture there, make superstructures, in general, use it to the full as an additional surface. The coating of an unexplosable roof is not adapted to increased loads, but the insulation of both species passes according to the same scenarios.

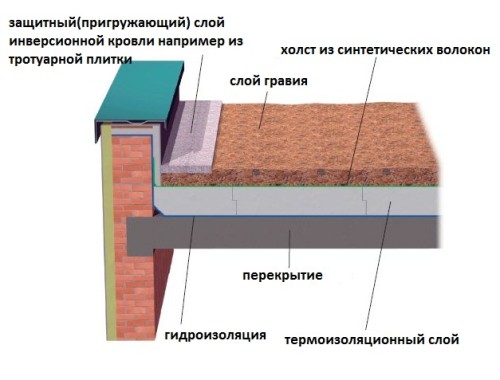

Inversion roofing in technical design is much more perfect than traditional. First, a layer of gravel, expanded clay or gravel is poured onto the bearing plate. The thickness of the powder should be at least 5 cm. Waterproofing is placed on such a drainage pillow, then the insulation, everything is poured with concrete and the screed is covered with finish material. The main difference in laying the insulation above the waterproofing, which allows you to protect the hydrophobic layer from destructive ultraviolet rays, temperature differences and mechanical damage. As a result, the inversional flat roof serves much longer than traditional and automatically becomes operated - a strong concrete screed (especially if it is reinforced) allows you to arrange sites for rest and sports in the open.

It should be borne in mind that various types of loads will be provided on the insulation, as well as on all other layers of the roof pie: snow, wind strength, mass of overlying materials, etc. Therefore, increased physico-mechanical requirements are presented with heater for flat roofs. In addition, experts strongly recommend choosing the most hydrophobic material as possible, since it is impossible to guarantee 100% protection from moisture. We will talk more about the choice of insulation a little later.

Ways to insulate flat roofs

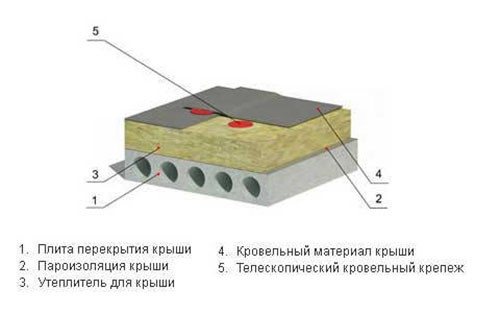

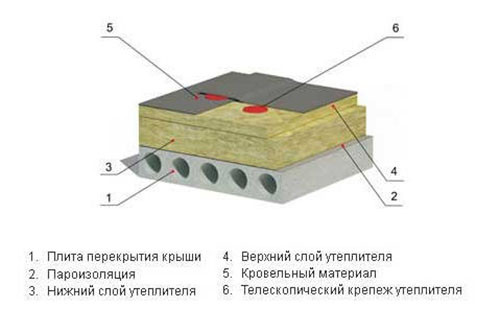

Warming of flat roofs is carried out according to one of two circuits: in one or two layers. Single -layer insulation is relevant for industrial buildings, garages and warehouses. Suitable for operated and unexploited roofs (in the first case, the presence of a reinforced concrete screed is mandatory). The placement of insulation in one plane gives moderate protection against condensate and excessive heat loss, however, only two -layer insulation allows you to create a comfortable microclimate for a cozy life.

The two -layer insulation scheme, as you might guess, involves laying two layers of thermal insulation material in different planes. The lower main layer should differ in thermal stability with low strength and thickness from 70 to 170 mm. The upper layer is responsible for the distribution of mechanical load over the entire surface of the system. Its thickness is significantly smaller than that of the lower layer, and is from 30 to 50 mm, but at the same time is highly strengths of compression and gap. Such a functional distribution of two layers of insulation significantly reduces the mass of the roof pie as a whole, thereby reducing the load shown by the roof on the ceilings and the foundation.

Choosing a roof insulation

A variety of materials are used for insulation of a flat roof outside, but after studying the above information, we can already distinguish several basic selection criteria. Firstly, maximum hydrophobicity. Secondly, strength and density. Thirdly, as low as possible. Consider the materials used in modern construction.

Most often, in urban and private construction, filling materials are used due to their availability and cheapness. We are talking about expanded clay (foamed under high pressure of clay) and perlite (light coarse -grained sand with good thermal insulation characteristics). Unfortunately, the low cost and accessibility of the dignity of these materials is limited - in other parameters they are not able to compete with fibrous or polymer insulation. They are relatively heavy, and it is quite difficult to create a perfectly even surface under a small slope.

The second most popular are mineral wool slabs and polystyrene foam. Mineral wool holds heat well, convenient in work, does not burn, but needs high -quality waterproofing - if it gets wet at least a little, it will stop protecting from heat loss. Extruded polystyrene foam is not afraid of water, is characterized by high strength, ease of installation and relatively low cost. However, it is better to use it to create an inversion roof, since the material is very sensitive to ultraviolet radiation and is distinguished by combustibility.

. For so long ago, mineral wool in the plates, made of basalt rocks, appeared on the market for so long. It is much stronger to compress and gap than the older analogues, is not so afraid of water and allows you to create a fairly strong coating without arranging a heavy concrete screed.

And finally, the most new, high -quality and expensive heater is polyurethane foam. A special composition is applied to the prepared surface by mechanical spraying, after which it is foamed, freezes and creates a solid waterproof crust that is perfectly holding heat and immune to ultravioleture. In the West, polyurethane foam has long been used to warm roofs, including flat ones. In our latitudes, its advantages have just begun to appreciate.

Positive moments of use of polyurethane foam for roof insulation:

- very low thermal conductivity (polyurethane foam 0.022 W/m², minvata 0.055 W/m²);

- it requires minimal surface preparation (cleaned of garbage, you can not align or process);

- for high-quality insulation, a layer of 5-6 cm thick is enough;

- absolutely seamless coating, which eliminates the formation of potentially risky places of leaks and drafts;

- absolute hydrophobic and vapor permeability (allows you to save on hydro- and vapor barrier);

- spraying can be used to create additional waterproofing;

- the high rigidity of the frozen coating allows you to equip a concrete screed on top of it;

- relatively low density (does not give a strong load on the supporting elements);

- environmental safety;

- the ability to cover surfaces and objects of any shape (allows you to protect the problem areas of pipes from leaks and heat loss);

- does not burn and does not support combustion;

- service life is more than 25 years;

- high speed of work.

Thus, polyurethane foam replaces the insulation, and steam, and waterproofing. The only drawback is that you can’t do such a job with your own hands, since this requires special equipment and handling skills with two -component material.

Technology of insulation

It is time to tell how to insulate a flat roof yourself. Since the disadvantages of bulk insulation do not allow us to talk about them as the best options for arranging, we will touch on the use of mineral wool plates and extruded polystyrene foam.

Mineral wool slabs

Immediately builds a reservation that far from all sorts of mineral wool slabs can be used to warm a flat exploited roof or a classic soft roof. Basalt plates are best suited for this purpose, fibers in which are directed in different directions - this allows them to withstand high loads. Of course, you can protect the fragile insulation with a screed (dry or wet), but this will create an additional load on the supporting structures.

Mineral wool insulation technology:

- The basis for laying are reinforced concrete floor slabs or metal profiled sheets.

- Regardless of the type of base before laying the insulation, it is covered with a vapor barrier membrane. If you neglect this moment, over time, mineral wool slabs are saturated with condensate and cease to retain heat, and waterproofing laid over them will be decorated with “blisters”. Steaming membranes are one- and bilateral. In the first case, between the membrane and the base, it is necessary to leave the free space literally 3-4 cm so that the condensate can evaporate freely. When using a bilateral membrane, the ventilation pocket is not necessary to leave. As an alternative to membranes, you can use the usual building polyethylene or melted materials (bitumen, polymer bitumen). As a result, vapor barrier should close all horizontal and vertical planes, and you need to start the coating just above the level to which the insulation will reach.

- Mineral watering plates should be laid in one or two layers. In the second case, you need to calculate in advance the thickness of the future roofing cake and, if necessary, strengthen the thermal insulation with a layer of thin and high -strength plates. Usually this is done in the northern regions, where the level of humidity and temperature fluctuations are so large that it disables ordinary heaters.

- Tescopic dowels are attached to the base of the plate or glued to bitumen - the method depends on the type of base. It is better to use dowels for a profiled sheet, but they are suitable for concrete slabs, but fasteners for concrete are more expensive than for metal. If you prefer a mechanical method of fastening, vapor barrier should be salated. Glue the insulation on bitumen is quite troublesome and expensive, but this method is recommended for insulation of roofs with concrete bases. A layer of bitumen is applied to the surface and stoves are glued. If you need to create a second layer of insulation, the surface of the first layer is smeared with bitumen and additional plates are glued to it “into a run” (so that the joints of the second layer do not coincide with the joints of the first).

- If the insulation was fixed mechanically, then waterproofing on top of it should be fixed in the same way, that is, using dowels.

Video about insulation of a flat roof with mineral wool:

Extruded polystyrene foam

Extruded polystyrene foam is characterized by high strength and water resistance, and therefore is most often used to warm inversion roofs. There are slotted locks on the plates, which provide a very dense surface, but for greater reliability, it is recommended to glue all joints with construction tape.

The charm of polystyrene foam is that working with it is very simple and fast:

- First, the slabs are laid on the base plate, gluing the cracks of the joints with construction tape. If you need to lay the second layer, the plates are mounted "into a run."

- On top of the polystyrene insulation foam, geotextiles are led, designed to protect the lower layers of the pie from pollution and mechanical damage.

- A layer of gravel or gravel is poured into geotextiles 5-10 cm. Sometimes, for additional drainage between geotextiles and powder, a profiled membrane is laid.

- Finally, crushed stone or gravel is filled with screed and laying the finish coating. If lawns or flowers are planned to be planted on the operated roof, an additional layer of geotextiles should be linked on top of the backfill, and then pour 15-20 cm of fertile soil.

It is not so easy to warm a flat roof, but this measure refers to the category of necessary if you want to live in a warm house and not overpay for heating.