Today, the problem of conservation of energy resources is becoming more and more urgent. One of the effective measures allowing to warm the room, while spending the minimum number of resources, is the installation of modern window structures on a metal -plastic basis. Metal -plastic windows have such properties as tightness and heat insulation. But in order to increase the heat -saving ability of window structures, it is necessary to perform high -quality slopes insulation. This measure will create a comfortable temperature regime in the room. In addition, due to insulation, window structures will be able to maintain their operational characteristics for a longer period.

Content

Varieties of structures

The slopes are called the outer or inner surface of the window opening from the frame to the wall. These elements perform several functions. First of all, their presence gives the window a complete and more aesthetic appearance. The slopes also prevent the penetration of noise into the room and provide thermal insulation. There are several types of structures that vary in the finish method, used materials and functionality. Let us consider in more detail the main types of slopes:

- Slopes of drywall material. They have good heat -insulating properties and a relatively affordable cost. However, operational characteristics are inferior to subsequent types of structures, since they can only be installed on the inside of the room. The reason for this is the instability of the material to moisture.

- The most economical option is slopes using plaster. A plastered composition in two layers is applied to the surface of the opening, and after its drying - a soil mixture and paint. Such a slope can last a fairly long time, but has a number of disadvantages. The plastering slopes have relatively low indicators of heat -saving properties, and as a result of temperature differences, cracks can form in them, the installation process is quite laborious. In addition, plastic and cement are incompatible with each other, as a result of which it may be necessary to eliminate the clearances between the window and the slope.

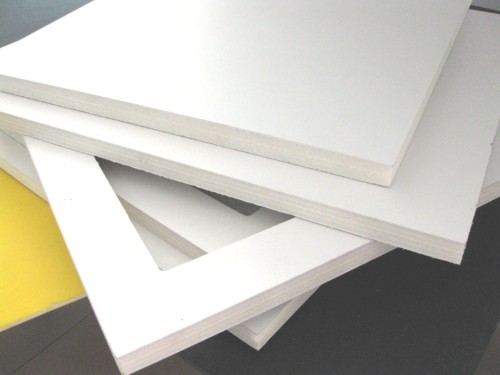

- The most durable slopes on a plastic basis are recognized. They are resistant to moisture and sunlight, and also combine well with plastic windows. Insulation of plastic slopes can be performed using mineral wool or foam. The working surface must be thoroughly cleaned of pollution, eliminated all defects. Then cut the insulation of the required size and fix it with glue. Then, along the perimeter of the slope, it is necessary to drill holes into which the plastic dowels are scored.

Ways of insulation

Windows insulation of windows can be carried out in three methods. In this case, these methods can be used for window structures of any type. However, insulation options differ among themselves depending on the material used:

- insulation with mineral wool;

- insulation with mounting foam;

- warming with foam.

Using these methods, slopes are insulated from the inside.

The use of polystyrene as insulation

The use of this material makes it possible to further perform the design of the structure using decorative panels, putty or plaster. The slopes of the slopes with foam are carried out in the next sequence of actions.

- Initially, it is necessary to prepare the wall with which the exfoliating layer of the finish is removed. If there are any defects on the surface, they should also be eliminated. To fill in cracks, a construction solution is used. In addition, at the preparatory stage it is necessary to take measures to prevent the appearance of various microorganisms under the insulation. For this, slopes are treated with special antibacterial compounds.

- After the preparatory work, you can proceed directly to insulation. Work is recommended to carry out in warm dry weather. From the foam, it is necessary to cut the corresponding size fragments and attach them to the slopes by means of mounting fungi or glue.

- When working with polystyrene, a moderate amount of adhesive should be applied. Since this material has the ability to increase in volume when heated and cracks may appear on the too thick layer of glue.

- To determine the necessary parameters of the material, it is necessary to measure the slope, add 1 cm to the resulting result. To fill the docking joints between foam fragments, installation foam is used.

Features of the use of mounting foam

This method is advisable to use if there is a free space between the opening and the window profile. Features of the work are reduced to such aspects:

- Between the profile and the base of the opening, construction foam is laid and thus sealing the mounting seam. This procedure should be performed using an mounting gun. Sealing is performed on both sides of the slopes.

- In addition to the slopes, insulation under the windowsill and tide should be performed in order to exclude the likelihood of heat loss. Installation foam can lose its thermal insulating properties as a result of the effects of ultraviolet rays. To prevent this, foam needs to be covered with the construction composition. You can check the quality of the work as follows: moisturize your hand and place it opposite the mounting seam, if the cold is not felt - the insulation is performed correctly.

- In order for the design to not only maintain heat, but also have an aesthetic appearance, the opening must be closed by means of decorative panels. For this purpose, you can use plastic, moisture -resistant drywall or MDF. Focusing on the size of the opening, it is necessary to cut the decorative elements of the corresponding parameters using a mounting knife or electrician.

- Further, the starting profile is attached to the base of the window profile, in which the upper panel and side panel elements are started.

- Fixation is performed using mounting foam, which must be filled with the space between the base of the wall and the slope.

Insulation with mineral wool

Warming with mineral wool slopes is carried out using the same technology as insulation with mounting foam. The only difference is that the space is filled with mineral wool, and mounting foam is used to fix the material. There are three types of insulation based on mineral wool:

- Soft insulation materials have the highest thermal insulation qualities, but they have a large volume.

- Semi -rigid heater differ in a smaller volume, but at the same time their thermal insulation ability is much lower.

- The most thin are hard heater, but their insulation qualities are minimal. For this reason, they are used only in combination with other types of materials.

To obtain a qualitative result, insulation of slopes of plastic windows must be performed not only from the internal, but also of the outside. It is recommended to start insulation precisely in external work, since in this way it is possible to significantly reduce heat loss.

External insulation technology

Mineral wool or foam is used for external work. In addition, you need to prepare:

- reinforced net;

- adhesive mixture;

- paint;

- primer.

The technique provides for this sequence of actions:

- The work should begin with the elimination of pollution and mounting foam from the base.

- Next, a primer layer is applied to the surface, which should dry well.

- At the next stage, it is necessary to measure the height and width of the slope and, in accordance with the resulting parameters, cut the net and insulation. At the same time, when cutting the grid to the resulting width indicator, you need to add 20 cm, and cutting the insulation material to make a 2 cm wagon.

- Next, the insulation is mounted. The adhesive mixture is applied first to the slope, then to the insulation. Then the material is glued to the slope.

- Then, a grid is attached to the insulation with glue. It is necessary to glue on the side, which is closest to the window, leaving a 10 cm wall at the same time.

- The remaining fragment of the grid is distributed along the slope and wrapped on the outer wall. The glue should dry well. After another layer of adhesive mixture is applied.

- After this layer dries, putty is performed, then the grout and application of the soil layer.

- The final stage is painting.

Another option for external insulation is thermal pimps. These are products made on the basis of foam and having a protective-decorative coating of acrylic binders and marble chips. Of the two fragments of the thermal podkos, the thermal contribution is formed. This type of insulation material has a number of positive characteristics.

Due to the ability of marble crumbs, the material does not burn out to the sun's rays. Decorative coating is resistant to fire. A wide color scheme will allow you to choose thermal sample for every taste. The insulation of the slopes from the outside is a necessary measure, since when warming only on the inside, it will not be possible to completely prevent the penetration of cold air.

Criteria for choosing material for external and internal insulation

The material of external slopes should have the following properties:

- resistance to atmospheric factors for a long period;

- stability to deformations;

- adhesive strength;

- water resistance;

- vapor permeability;

- providing the possibility of unhindered removal from the mounting seam of moisture.

For internal work, you need to choose materials, given the following criteria:

- steam resistance;

- durability;

- good adhesion.

The process of insulation has its nuances depending on the design features of the external wall:

- There is no need to insulate the slopes if the wall consists of several layers, among which there is a warming material. And also in the presence of facade insulation of the enclosing structures.

- With a single -layer outer wall, preference should be given to thermal insulation liners, which must be placed along the entire perimeter of the window.

- It is necessary to ensure that the insulation fit tightly to the base, and air layers do not form. This can be achieved by tightly pressing the material to the surface.

The durability of thermal insulation depends on several factors. First of all, this is the level of quality of insulation. To choose high -quality material, you should pay attention to its cost, a good insulation cannot be cheap. Therefore, it is not recommended to purchase a material related to a low price category, this will be unjustified savings. Also, in order for insulation to retain its qualities for a long period, the work must be done in accordance with all technological requirements.

Finish finish options

After the end of the slopes insulation, if desired, they can be given an attractive and original appearance. This can be done in several ways.

- The most common method of river decoration is painting. There are several technologies for performing this type of work. The simplest is the application of paint with a sponge. Pre -moistened with a sponge in paint, prints on the surface are made. You can complete a combination of several colors. Another way is to apply paint with a stencil.

- An interesting solution will be the use of cork wood. This material has good heat -insulating qualities. Therefore, its use will solve not only a decorative task, but also to make slopes even warmer. If desired, a panel made of cork wood can be covered with a layer of varnish.

- On slopes, you can also glue wallpaper.

Conclusion

Thus, we can conclude that the insulation of slopes plays a significant role in the process of thermal insulation of the room. In this case, the same significance is conducting insulation work, both indoors and outside the building. Today there is a significant selection of insulation materials and various methods of insulation. All stages of the technological process are based on simple, affordable actions, which allows you to insulate the slopes with your own hands.

Video insulation of slopes: