Roof insulation with foam – this is an important stage in the construction of a residential building, and therefore it is necessary to approach the performance of work carefully and conscientiously.

Content

The temperature in the rooms, the level of humidity and the general comfort of human residence will depend on thermal insulation of the roof. Modern manufacturers offer a wide variety of materials for insulation: polyurethane foam, expanded clay, mineral cotton wool, ecowata, basalt slabs, foams, etc. But the polystyrene foam remains the most practical and inexpensive.

Advantages of using foam

Many homeowners faced such a task as thermal insulation of the roof. Since the installation of insulation materials often has to independently, it is necessary to clearly understand how to insulate the roof of foams in what the appropriateness of the use of this material. Consider the main advantages of polystyrene foam:

- high resistance to temperature differences;

- environmental safety;

- lack of tendency to deformation;

- ease of processing with tools and ease of installation;

- it has a low indicator of the thermal conductivity coefficient, so it does not heat up in the summer of the year;

- suppose use in high humidity conditions while maintaining functional parameters;

- the minimum weight of the material allows you to thermal insulation even bearing structures;

- long service life;

- prevents the propagation of bacteria;

- the material is hypoallergenic.

Disadvantages of polystyrene foam as insulation

Despite the impressive number of advantages of using polystyrene foam as thermal insulation material, this type of raw materials has some disadvantages. Depending on the degree of their importance, it is necessary to decide whether it is possible to insulate the roof with foam. Consider the negative aspects of thermal insulation with this material:

- polistyle foam has quite high soundproofing qualities, however, it is less suitable for insulation of “noisy” metal roofs than cotton sheets;

- contributes to the formation of moldy fungus;

- due to the fact that the hard layers of foam are not always shared by the roof insulation, the voids may remain in the space between the structures in which the cold bridges are formed and condensation accumulates;

- when the material is ignited, toxic gas is released.

Important! In order to eliminate the risk of mold and fungus, it is necessary to take care of high -quality waterproofing during the laying of the material.

Necessary tools and materials

Before starting work on thermal insulation of the roof with foam leaves, it is necessary to prepare the following:

- waterproofing film;

- construction stapler;

- wooden rails;

- vapor barrier membrane;

- sharp knife;

- polystyrene foam;

- scissors;

- self -tapping screws;

- mounting foam.

Roof insulation with foam: phased work

Thermal insulation of the roof will create a comfortable microclimate in living space, protect the roof from heat loss and freezing in the cold season of the year. Remember that the final result entirely depends on the conscientiousness and quality of the implementation of each stage of work. Consider them in more detail.

Preparation of the surface of the roof

Thermal insulation of the roof using polystyrene foam can be produced by various methods, among which such as:

- investment in the crate;

- flooring;

- gluing sheets (using facade frost -resistant compounds, liquid nails or mastic);

- mechanical fixation of polystyrene foam (by means of questionnaires, nails or wooden racks).

In this case, some rules for the preparation of the surface before starting work should be followed. Consider the sequence of actions:

- Initially, it is necessary to clean and carefully dry the surface on which thermal insulation material will be laid.

- Since any roof consists of the internal and outer part, it is necessary to check the rafter frame and the roof itself for damage and carry out repair work. Beams that could bend should be replaced with new ones and the structures are processed by a firewall chemical composition.

- To lead the formation of moldy fungus, the inner surface of the roof should be treated with a special composition or antiseptic, which prevents the growth of microorganisms. In this case, all metal parts must be covered with anti -corrosion liquid.

- The roof insulation with foam from the inside requires a scrupulous selection of insulation materials, their thickness and quality. If the width of the foam sheets is smaller than the distance between the rafters, this will entail the formation of cracks and cavities where condensation will accumulate.

- Be sure to think over the vapor barrier and ventilation holes between the rafters and the insulating material to avoid decay of the roof frame.

Choosing foam for isolation

Before starting work on thermal insulation of the roof structure, you need to know for sure whether the overlap can withstand the alleged load of the material. For this reason, choosing polystyrene raw materials, follow the parameters of its density. So, for thermal insulation, the following types of material can be used:

- polistyle foam with a density of 15 kg/m3 - perfect for insulating ceilings, as well as napal and attic surfaces;

- extruded foam - used to finish the attic and gentle roofs, where mechanical loads are provided;

- foam with a density of 25 kg/m3 - serves for wall insulation.

The process of insulation of a flat roof

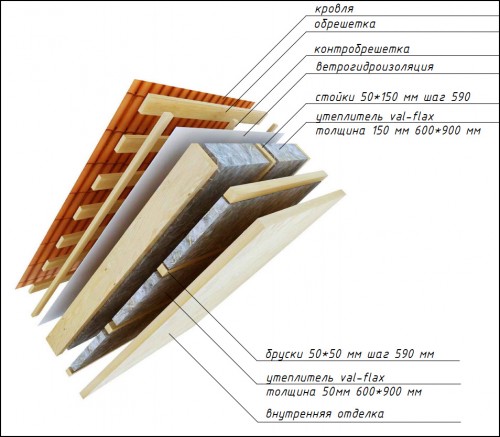

The correct design of the thermal insulation of the roof includes:

- hydraulic layer;

- directly insulation;

- vapor barrier layer;

- interior decoration.

Also, in this design, it is necessary to leave small cavities for the airspace, which will be located between the roof and the waterproofing layer. This will avoid unwanted concentration of condensate.

The sequence of actions to warm the roof with polystyrene is as follows:

- The priority task is to measure the distance between the rafters, as well as the thickness of the wooden rails themselves. You need to perform work with an accuracy of millimeters.

- Start cutting thermal insulation layers: the width of each fragment should be 1 cm larger than the distance between the rafters.

- Next, foam laying occurs. The process must be done so that there are no gaps between the insulation. Otherwise, cold will begin to accumulate in the cavity and condensate forms, which worsens the thermal insulation of the roof.

- If you could not avoid the cracks when laying foam, carefully fill the cavity with mounting foam.

- After the installation of polystyrene foam, you can start laying a vapor barrier membrane, which should be fixed using a construction stapler to wooden rafters.

- In the process of laying a vapor barrier film, it is necessary to adhere to the rule-layers need to be laid out, making a lining of 5-6 cm. At the same time, the edges of the film need to be glued with foil tape. This will ensure thermal insulation maximum protection against cold penetration.

Thermal insulation of the attic roof

Quite often, the attic space becomes a living attic. In particular, this technique is in demand if the house has a gable roof. As a result of the arrangement of this premises, the owner of the home receives a full area of \u200b\u200bthe building. Moreover, the process of insulation of the attic roof with foam is the most optimal solution among all possible thermal insulation options.

To insulate the attic roof, it is necessary to carry out work on laying polystyrene plates between the rafter fractions. In general, the thermal insulation process looks as follows:

- The measurement and cutting of polystyrene plates occurs on the sheets of the required size.

- Then the material is located between the rafters so that they lie down as tightly in the designated space. Foam must be fixed with special glue or use screws.

- The trace of this must be laid by the waterproofing film, fixing it by means of adhesive or construction stapler.

- Also on top of the foam, at the request of the owner of the house, a roofing layer can be laid or a cement-sand screed with reinforcement can be produced.

- After that, you can start finishing the inside of the attic, mounting drywall or other finishing material.

- At the request of the owner, the surface is decorated with any selected way.

Important! In places where the insulation is coat with a rafter structure or roof, it is necessary to perform additional sealing. For this purpose, ordinary mounting foam is suitable.

Tips for professionals

Many homeowners prefer to perform work on the thermal insulation of the roof on their own. However, they often allow oversights that reduce all efforts to “no”. Consider a number of the most common errors:

- The use of poor -quality materials, violation of the order and technology of work.

- Assumption to the installation of polystyrene material on which there are defects or mechanical damage to sheets in the laying process. Such a careless attitude contributes to the formation of cavities and cavities in the thermal insulation layer, where condensate is collected, and subsequently freezing, mold and dampness.

- The cause of poor tightness can also be an incorrectly selected width of the layers of polystyrene foam.

- Another mistake is the use of a polyethylene film instead of a vapor barrier membrane, which significantly worsens thermal insulation parameters.

Detailed instructions for roof insulation with foam on the video is presented in a fragment :