Today, houses from natural materials are becoming more and more popular. After all, they have many advantages that together make living in them very comfortable and comfortable. However, insulation of a wooden house is required, since the tree independently will not be able to provide a sufficient level of thermal protection. Only by insulation of the walls, you can get normal living conditions in the room in the winter. The wooden house, which is processed using thermal insulation materials, can maintain heat for a long time, which increases its life. If it is necessary to select the methods of insulation, usually many questions appear, to which not everyone can give an unambiguous answer. It is with these obscure moments that we will try to understand this article. In particular, we find out how to properly insulate the walls, which material to choose for this, and how to equip a crate for wooden walls.

Content

The main points

According to experts, for each owner of a private wooden house, the issue of wall insulation should be one of the most priority. Walls can be insulated both outside and inside. Each of these methods has its own advantages and disadvantages. So, the main “weak side” of internal insulation is a decrease in the area inside the house. In addition, condensate often accumulates between the wall and the heat insulator. If the installation of the insulation is poorly performed, the harmful effects of the external cold environment will be provided on the walls, which can eventually lead to cracks and splitting.

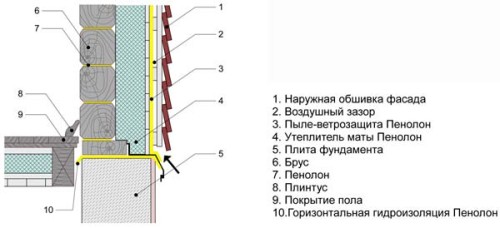

The insulation of a wooden house should be carried out using special technology. The order of the layers of the insulation "pie" is important. The first layer in the structure of the insulation system should be the flooring of vapor barrier. It is he who protects the house from wet air entering the thermal insulation layers. Thanks to this, the wooden bars from which the building has been erected become less susceptible to debate and rot. After laying vapor barrier, they begin to install thermal insulation. This layer will preserve warm air inside the building.

Next, it is necessary to lay the third layer - waterproofing. He is able to retain moisture and condensate. Before starting to warm the house, it is necessary to decide on which side this will be done - outside or from the inside. The walls of logs are best insulated from the inside, if only because the house does not lose its appearance. It is also important to choose the right material for insulation of wooden houses.

Now consider the technology of insulation of the house erected from the galled timber. Here it is necessary to take into account that the installation of the thermal insulation layer cannot be done in the places where the floors are adjacent to the walls. The fact is that zones will form here, where heat is very quickly lost. These places are also called "islands of cold." With external insulation, you will receive the same heat loss throughout the area of \u200b\u200bthe wall. A sharp temperature difference is usually noted closer to the outer walls. At the same time, the "islands of the cold" are located just where the thermal insulation layer is laid.

It is possible to regulate humidity in the house thanks to the wall cladding with materials that have a dense structure and do not let water vapors. Mesideous heaters are best put on the outside. At the same time, you can protect the wall from the influence of cold and precipitation flows using the heat -insulating flooring from mineral wool. Thus, the house will maintain heat for a long time.

From the shortcomings of external insulation of the house from the beam, it can be noted that this is a rather difficult job. In this case, the final appearance largely depends on the selected material. If there is no experience, you can entrust installation work to specialists.

Insulation of a wooden house outside

When performing such external works, the thermal insulation layers are located in the middle between the walls. As a rule, the following types of insulation are used for this:

- Mineral (basalt) cotton wool.

- Polystyrene, or as it is also called polystyrene.

The popularity of these materials is due to their strengths:

- Fire safety. Polistyle foam and basalt cotton wool are not ignited from open fire, they only smolder, not allowing the fire to spread on.

- Air and vapor permeability. Thanks to these qualities, they create a thermos effect inside the house, maintaining heat. This allows the owners of a house insulated using this technology to spend less energy funds.

- Moisture resistance. These materials not only are not afraid of moisture, but also perfectly divert it from wooden walls, which positively affects the tree.

To close up the cracks between the logs of the wooden house, felt, linen pacly or jute is suitable.

The procedure for performing installation work:

- Before starting work from the surface of the walls, all additional elements are removed: slutters, shutters, drainpipes, etc.

- First of all, work on the installation of vapor barrier is carried out. For this, as a rule, PVC film is used, however, aluminum foil or roofing material is sometimes used. During the installation of vapor barrier, special attention should be paid to its tightness. To do this, laying with an overlap at least 55 mm, which is fixed with the help of clamping wooden strips, or simply fastened with nails. The place where the nails are clogged are sealed with mounting tape.

- To prevent the accumulation of condensate on the surface of the vapor barrier, it provides for technological holes with a diameter of at least 18 mm. Thanks to them, the incoming warm air from the surface of the wall will contribute to the drying of condensate. If the house is built of a galbed timber, there is no need for technological holes. Indeed, in this case, the air will freely flow due to irregularities of the surface.

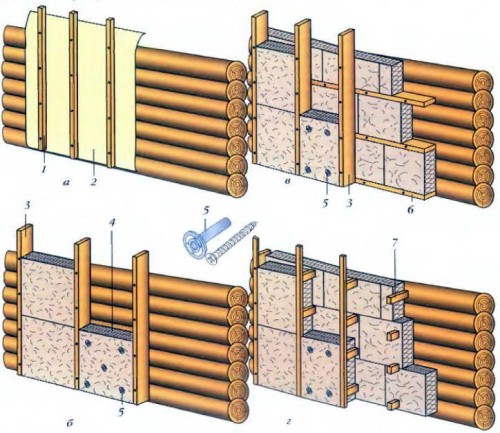

- After laying vapor barrier, you can install a wooden frame. As a material for it, pine slats or spruce with a thickness of 40-55 mm are used for it. They are installed perpendicular. If horizontal boards are nailed on top of the vapor barrier layer, then the vertical is fixed only after the first layer of mineral wool is laid.

- For insulation of the walls of a wooden house, soft slabs of mineral wool are used. Its density should be about 90-110 kg/sq.m., and the width is 45-55 cm. This material is quite elastic and flexible, so that it can be reliably attached to the frame. In addition, the strips will not be deformed due to the influence of wind and their weight.

- It is recommended to lay the material slabs so that there are no gaps. The lines along which the layers are connected should be even. You need to carefully measure the joints of the material.

- Next, you need to provide design protection against wind exposure, i.e. Make sure that the insulation does not blow out. For this purpose, a plastic film is used, which has good vapor permeability. A thin roofing material is also suitable, but this material is considered less effective. Sometimes the packed paper is also used.

- According to the insulation scheme of a wooden house, the protective layer should be laid directly on the mineral wool, nailing it to the crate with nails. In addition, it is necessary to overlap about 6-8 cm.

- Through a self -adhesive tape, it is necessary to seal joints. Between thermal insulation and skin boards, a metal mesh should be fixed, so precipitation will not get inside. In addition, this will protect the structure from various insects.

- In order to finish with external insulation, it remains to install facade boards that are usually made of pine, larch or oak. The specified type of wood best withstands different atmospheric phenomena. Before installing the bars, they should be painted or varnished. It will protect from moisture.

The technology of laying the material largely depends on how you want to see your country house. So, for example, boards on the facade can be cleaned both vertically and horizontally. On this, the device of external insulation can be considered complete.

Insulation of a wooden house from the inside

Today there are several methods of insulation of the house from the inside. One of them is the “warm seam” technique. It is used if the wall after insulation is not faced with various decorative plasters. This method can minimize the thermal conductivity of the joints and seams of the walls. The material is placed directly between the logs of the wall. In this case, insulation are synthetic sealants. These, in particular, include silicone, acrylic, latex and bitumen-teddy mixtures. You can also use natural sealants, for example, such as Lnov, Packl and Flax Veria.

It should be noted some advantages of the “warm seam” methodology. So, first of all, this is a fairly simple technique for insulation of a wooden house with your own hands. In addition, it is beneficial from an economical point of view. Also, this method allows you to increase the thermal insulation properties of the wall, without violating the appearance of the building. In addition, this method has vapor permissive power, and this favorably affects the microclimate in the building. Of the rarely used can be called insulation of a wooden house with a foam.

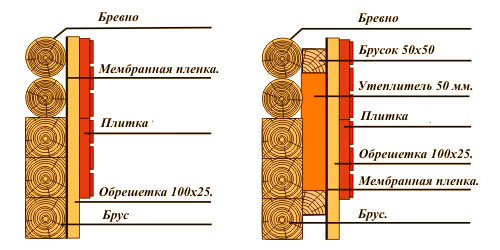

One of the most popular ways is to warm the wooden house with mineral wool. Consider it in more detail. The insulation material will be mats made of mineral fiber, glass wool or slag fiber. In general, Minvat has good heat -insulating properties, but it would not have become so popular if it had not had some other useful functions. So, this material can act as noise insulation, and only environmentally friendly components are in its composition. But because of a fibrous structure, he can pass through himself steam and accumulate moisture. Therefore, only in mineral wool during insulation can not do. In any case, it will need to be installed in layers of steam and waterproofing.

Next, we will analyze the order of insulation from the inside:

- According to the technology of insulation of a wooden house, first of all, you need to close all the cracks and cracks that are in the masonry. This can be done using various synthetic sealants. In addition, the wall must be treated with an antiseptic.

- Then you can proceed to the arrangement of the crate, which consists of two parts. The first of them is the transverse crate, which is made of metal profiles. They are usually placed so that there is a distance of about 0.7 m between them. Moreover, they are located across the log masonry.

- The second part of the crate is a counter -makeup that is made from the same metal profiles. But in this case, it is already laid along the masonry. Thanks to the crate, it will be possible to attach Minvat to the wall and provide a ventilated gap, which will ensure the normal output of the steam excess. In addition, this will not allow condensate to form.

- After the crate, you can proceed to the installation of the insulation, in our case, mineral wool. Minvat is recommended to be used in the form of mats. The fact is that such a structure can withstand fairly large mechanical loads and thermal insulation properties will not be disturbed.

- The insulation, as a rule, is not glued to the surface of the wall. Usually it is laid between the metal profile of the crate. The seams should not be wider than 1.5 mm. The joints after are embedded with sticky tapes.

- After the insulation, you can do vapor barrier, which is usually laid, while making a small allowance so that the material does not break as a result of thermal expansion. It remains only to make the finish. It should be attached to a metal profile or lags if your frame is made of them.