In the process of construction, flaws are possible, which manifest in winter. One of the common problems is the freezing of the base of the house. This problem is eliminated by insulation of the base from the outside of the house. Check out how the insulation of the base is equipped, the video of the necessary work is at the end of the article.

Content

Thermal insulation of the basement of the house normalizes the microclimate in the room. The insulation protects the lower part not only from freezing, but also from melt or groundwater. Warming materials for the basement of the house are selected with a waterproof base and are calculated for subsequent cladding. Soft mineral wool is rarely used for insulation of the basement, more practical and popular in this case, plate of polystyrene or foam. After insulation, the base is plastered and finished with a facade decor.

Materials for insulation of the base of the house

Materials for insulation of the basement of a private house have various characteristics and price. Polyurethane spraying is an effective, but expensive methodology. It is quite difficult to perform such insulation yourself.

- DIY basement insulation is made of more traditional materials. The technology for installing insulation plates of polystyrene, polystyrene or foam polystyrene is largely similar. After installation, the insulation requires plastering and finishing.

- Mineral or basalt cotton wool is acceptable for insulation of the basement of the house, provided that the installation technology and installation of the protective-decorative layer is observed. The process of insulation with mineral wool of the basement of the house is visible in the photo.

The process of insulation of the base of the house with polystyrene foam

Extruded polystyrene foam is a durable, having a cellular structure, insulation material. It is easily processed with a mounting knife and firmly attached to the walls using special glue or mastic.

- A trench is stroked around the perimeter of the house before the start of the basement, and preferably to the base of the foundation. The insulated surface is cleaned with a metal brush from the ground, dirt and building debris.

- The purified and prepared basement surface is waterproofed. For the insulating layer, bitumen mastic is used, which covers the basement of the house with a hot or cold method. You can also waterproof roofroid or rubimaste.

- Polyteral foam slabs are produced in size 1x1 and 1x0.5 meters and from 30 to 120 mm thick. From the plates with an mounting knife using a straight rail, the parts necessary for installation are cut in size. A glue for insulation is applied to the closer side adjacent to the basement. Several spot strokes with a spatula, evenly distributed along the plane. The lower horizontal edge of the blank relating to the soil, and the upper, final edge is smeared with a continuous adhesive strip.

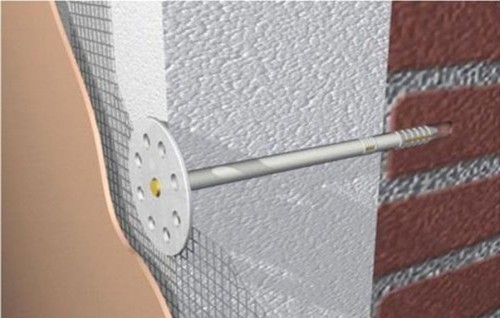

- When producing basement insulation, polystyrene foam plates are installed in the end, and the seams are additionally coated with adhesive solution. Plates are fixed with mechanically plastic fungi. 4 fungi in the corners and one in the center are installed on one sheet. Hats of fungi immediately after installation are covered with glue.

- Part of the basement insulated with polystyrene is delayed with a fiberglass grid and plastered. The grid of medium or high density is fixed on the insulation with plastic studs. From the center to the edges of the grid, the first, thin layer of cement-stucanular solution is applied. Then, after the first layer dries, the final layer of plaster with a thickness of up to 2.5 cm or the base is decorated with other finishing materials.

If necessary, a drainage system for the removal of ground or meltwater is equipped at the bottom of the trench. The trench is covered with crushed stone, a blind area is compacted and equipped.

Insulation of the basement base of the house with a foam

Foam is one of the varieties of polystyrene foam. Such a heater is more expensive, but also has some increased useful qualities.

- The coefficient of thermal conductivity in the foam is 50% lower than in similar insulation plates. The high density of the granular structure of the material does not contribute to absorption of moisture. In this case, the insulation has high plasticity, which simplifies its processing and installation.

- Before the start of insulation, the surface is aligned, cleaned, primed and covered with special polymer glue. Plates are installed in the end with the mandatory admission of a gap of not more than 5 mm. The resulting cracks are coated with glue and filled with scraps of the foam. Before installation, the inner side of the foams is emphasized.

- For stiff fixation of insulation plates, through holes are drilled and plastic mounts of the umbrella or fungus type are installed. At the time of installation of plastic mounts on the dowels, fiberglass or metal reinforcing mesh is mounted.

- The insulated surface is covered with a primer directly along the grid and plastered. After the plaster layer dries, the basement insulation is again primed and covered with finish finishing materials.

Using insulation from mineral wool for the basement of the house

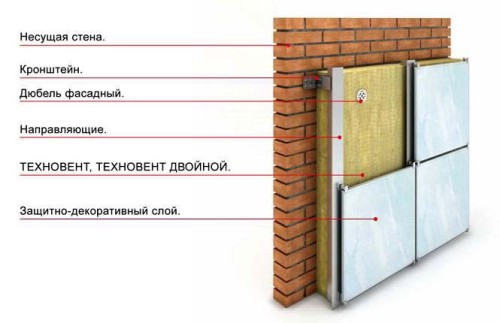

Mineral wool is produced in rolls or mats. Reliable mounting of the insulation is carried out using a crate from a bar. The timber is preliminarily treated with chemical protection against decay and mounted on the basement of the house with dowels.

- Wooden cells of the crate are made 2-3 cm less than the size of a mounted MATA of Mineral Vata. In this case, the insulation will fit tightly to the base of the house. Fasteners or brackets are installed in a wooden beam, on which facing material is mounted. Sometimes between the insulation and the external trim in the form of siding or plastic lining, a laying of polyethylene film is installed.

- Many types of mineral wool are designed for subsequent decoration by plaster. A metal reinforcing mesh is attached to the crate and a plaster solution is applied. A ceramic tile can be glued on a plaster solution or linen with a clinker.