The LED strip is a decorative lighting element with miniature diodes on the surface. Its length, as a rule, is 1-5 m. If necessary, the size can be adjusted and cut off the tape, but exclusively in places intended for this purpose. These products are mainly used as designer illumination when creating interiors. We will talk about all the intricacies of application and installation of the tape in this article.

Content

Features of the material

LED tape is exclusively decorative in nature, because It is not suitable for creating full lighting. These lighting elements have a fairly wide area of \u200b\u200bapplication - designers often use it when designing:

- ceiling structures;

- stairs;

- decorative niches;

- furniture;

- shelves.

Also, lighting tapes can be used for commercial purposes. With their help, the illumination of advertising products, attractions, concert venues, store windows is created.

Such an illumination makes it possible to simulate sunset, daylight or create any other light effect. Using LED strips, you can get uniform lighting that will not blind or create shadows. If desired, you can change the color and brightness of the backlight, which allows you to change the interior of the room. Due to its flexibility, the product is freely located on any structures. The tape can be cut into fragments, each of which is then separately connected. A significant amount of illumination has a self -adhesive base, which during the work you need to simply remove and attach the product to the right place.

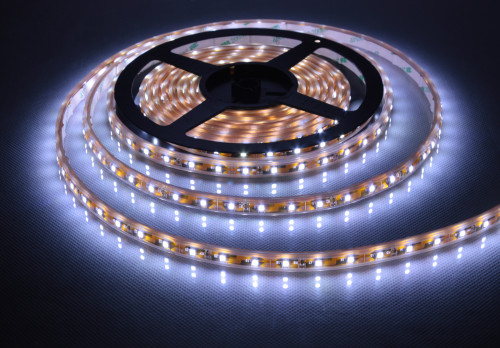

LED Strip Light. Photo:

Principle of operation

Such tapes work using special blocks with a fairly wide range of power-30-400 watts. To ensure the power of the backlight, it is necessary to connect the wire contacts to it by soldering, taking into account polarity. For connection, power and control, a special device is used - a controller that has three channels. The connection is carried out so that the plus of the lighting element is connected to the plus of the power source, and the minus, respectively with the minus.

In order to choose the right block for the LED tape, it is necessary to proceed from the required power indicator. When determining it, you should focus on the length of the product, as well as the number of LEDs, which is supposed to be connected and power by 1 m.

In addition, it is necessary to provide another 20% of the power as a reserve. It is also important to consider the output voltage. The choice is carried out in the following sequence:

- First you need to multiply the power consumption by the amount of meters of material.

- Further, taking into account the resulting result and voltage, the block is selected.

Varieties of LED strips

The ribbons differ from each other according to several criteria:

- One of them is the number of LEDs per meter. The backlight can have 60 or 120 LED elements. The more of them, the brighter the tape shines, and the lighting is distributed more evenly.

- The next difference is the color of the glow. A wide variety of color solutions makes it possible to realize any design plan.

- The ribbons also differ in the degree of protection and are divided by this criterion into the following types:

- ordinary;

- moisture -proof elements.

The backlights related to the first type are intended exclusively for installation in rooms protected from moisture penetration. Moisturing properties can be installed in rooms with a high level of humidity and even on the street.

Thus, 4 varieties of LED strip illumination can be distinguished:

- one -color products - they can be blue, yellow, red, white or green;

- multicolor - RGB ribbons that change the color using a controller;

- illumination with or without a self -adhesive base;

- ribbon with moisture -proof qualities.

The advantages of LED tapes

The use in the design of the LED tape has its undeniable advantages. Among them it is worth highlighting the following aspects:

- Simplicity of installation. Installation of LED tape is easy to perform independently without the help of specialists.

- Minor electricity consumption, which contributes to the savings of financial resources.

- Due to the ability to cut the product, you can form a tape of the required length.

- High efficiency. Unlike conventional lamps, 70 % of the energy of which is consumed on heat, LED backlights are spent on almost all of electricity for lighting.

- The ribbons do not emit ultraviolet radiation.

- In the case of voltage drops in the network, the backlight will not deteriorate.

- A wide selection of color solutions allows you to choose a product for any interior.

- Over time, the lighting quality does not deteriorate.

- The ribbons are made on the basis of environmental material and do not pose a health hazard.

- Lowering voltage in the network will not affect the work of backlight due to the presence of a power supply.

- Long period of operation.

Preparatory stage

The use of LED tape in design design is a very ingenuous way to create an extraordinary and aesthetic interior. At the same time, it is worth considering that the work begins with the appropriate preparation, which includes such stages:

- Before installation, the tape must be cut into fragments of the required length. The frequency of cutting depends on the density of the LED elements. This can be 3, 5 or 10 cm. The section of the section is quite clearly indicated by the manufacturer. Simple scissors are suitable for work.

- Next, you need to solder the wires. This requirement also applies to holistic tapes that were not cut. The wires are recommended to be replaced, since their length does not correspond to the necessary sizes, and some ribbons go on sale without wires.

- If such a situation arises, it can be fixed independently. For work, you will need a soldering iron with a low power - from 25 to 40 watts and a wire in size up to 20 cm and a section of 0.75 mm.

LEDs, like all semiconductors, cannot be overheated. For a one -color tape, it is recommended to use two wires of different colors. This will help to avoid an error with polarity in the connection process.

- The wires must be cleaned from both ends, then treated with rosin or tin and soldered.

- The ration of the soldering is recommended. To do this, you need a fragment of a heat -shrink tube 2 cm long, which you just need to put on a section of soldering.

- Next, this tube must be heated with a construction hairdryer with a special nozzle, which will prevent hot air from entering the LED.

- In the absence of a hairdryer, the use of a conventional lighter or matches is allowed, but the quality of work for this reason may worsen.

- This measure will make the soldering more durable and create isolation from various influences.

How to install LED tape

As noted above, for the maximum convenience of the consumer, many lights are available with a self -adhesive base. To work with those products that do not have such an advantage, you need to prepare a double -sided tape. Installation is carried out as follows:

- From the working surface, it is first necessary to remove dust and other existing pollution, then degrease the base.

- Next, the protective layer is removed from the backlight, after which it is pressed to the required place.

- On this, the installation of LED tape with your own hands is completed.

Despite the obvious simplicity of the installation process, the work should be carried out taking into account certain rules:

- Mostly the ribbon enters the points of sale in coils, in each of which is 5 m of material.

- If there is a need for division into fragments, the type of tape and the density of LED elements should be taken into account.

- You can combine in a single fragment no more than 15 m backlighting. This is enough for a ceiling structure in an apartment with a standard meter.

- If you need to light a large room, then this amount of material is clearly not enough. In this case, the most optimal output will be to divide the backlight into areas up to 15 m long. For each of them, a separate power source must be provided. Otherwise, if the electricity passes along the large sequentially connected fragments, a large voltage will be provided to the first tapes, which will ultimately lead to their rapid burnout. For this reason, it is recommended to divide the backlight.

- Installation of the LED tape on the ceiling is performed so that from below it is not within sight. To do this, the backlight is fixed at the protruding lower level, in its upper part. In this case, the light will be distributed along the upper level of the ceiling structure.

- When determining the distance at which the ceiling levels will be placed, it is important to consider the brightness of the tape. With insufficient space, the lighting will turn out to be uneven, and in this case the location of the LEDs will be visible. Excessively the distance will worsen the lighting, as the light will dissipate.

Connecting LED tape

First, consider the process of connecting a one -color tape itself. Its functioning will require a source with a voltage of 12 watts. Since the voltage indicator is 220 watts on the network, it is necessary to prepare the power supply. It is equipped with a network cord or two wires of the same color N and L, as well as two multi -colored wires. The polarity of the red corresponds to the plus, and the blue - minus. To connect, connect the backlight to the block output.

Now we will analyze how to connect the RGB LED tape, that is, the backlight, the color of which can be changed using a special device:

- In this case, in addition to the tape and power supply, you need to prepare the controller. It is connected to the wires of the block, taking into account polarity.

- Next, the backlight is connected to the controller. This element with the tape is connected by 4 wires, 3 of which are designed to control colors, and power is supplied to the 4th.

Important! RGB ribbons can have high -power LEDs that consume a significant amount of energy. Usually they are located in separate areas. The controller may not withstand such a voltage, and the power supply will turn out to be large. In this situation, it is recommended to use signal amplifiers.

You will need two power sources with a small power for connecting to the controller and amplifier. One end of the tape is connected to the controller, after which the wires are soldered to the second end and it is connected to the amplifier.

The principle of the amplifier is as follows: it has two pairs of contacts. One receives a signal, and through the other signal passes to the second partition section. Thus, the brightness of the sites and their color changes. A scheme of LED tape will help to understand this process in more detail.

Recommendations for the process

- The backlight should not have mechanical exposure, such as pressure or excesses. This will negatively affect the quality of the product.

- You also need to monitor the integrity of the paths along which current passes and nourishes the tape.

- The installation of the LED tape should be carried out on an aluminum profile, since this material has the ability to remove heat. And overheating as noted earlier, negatively affects LEDs, reducing their resource.

- At the installation stage, the possibility of repairing backlighting in the future should be provided.

- It is necessary to ensure the conditions for working with the soldering iron at the place of placement of the tape and block. For this reason, it is not recommended to install products behind stretch or suspended ceilings, since in this case, part of the structure will have to be dismantled in this case.

Possible mistakes:

- in the process of connecting the backlight and the unit, polarity is confused;

- using a power source with inappropriate power;

- mechanical loads on the LED cord;

- insulating measures were not taken when sticking the product to the surface conducting the electric voltage;

- conservative connection of long areas.

Conclusion

The main function of LED strips is the creation of a decorative effect. These lighting elements have a significant number of advantages that distinguish them from ordinary lamps. Among the main advantages, the ease of installation and aesthetic attractiveness can be distinguished. A certain number of tapes goes on sale with a self -adhesive basis, which minimizes efforts during installation work. The installation of products that do not have such a basis is also affordable and will not require qualified knowledge or professional skills.

Features of the connection of the tape are shown in the video: