When building a private house, the solution to the problem of heat loss is a paramount task for both designers and builders. Increasing the energy efficiency of the structure will help in the future to save a large amount of funds on its heating in winter and air conditioning in the summer. One of the most narrow places in terms of the heat loss of a wooden house are windows. It is through them to a greater extent it goes warm. Through old wooden frames that are loosely adjacent to the window box, the gaps between the frame and the glass on the streets are big money.

Content

- Why Metal Plastics?

- The need to install plastic windows in a wooden house

- Preparation of the installation site of the metal plastic window

- Montage of the window sill

- Preparation of windows to installation

- Installation of plastic windows in a wooden house

- Installation of glass packs

- Plastic window in a wooden house: video

Fortunately, with the advent of metal-plastic double-glazed windows, such a problem was partially solved. Similar windows have not only an attractive appearance, but also excellent performance. On how to install plastic windows in a wooden house - more.

Why Metal Plastics?

Metal plastic windows have long appeared in the building materials market and have already received their own piece of popularity. The positive sides of these designs are quite a lot, so that they practically wipe the wooden frames from the market.

Positive properties of metalplastic:

- Energy saving. Due to the fact that the frames of such windows are made of a polyvinyl chloride profile (PVC), which in the context of the hollow, air accumulates inside it. They have a low thermal conductivity, which reduces heat loss. Void inside the profile is called cameras. Quite often, people confuse the concept of "camera", believing that it means the number of glasses in the double-glazing. Thanks to the installation of double-glazed windows, which are manufactured by soldering 2 or 3 glasses, there is also an air layer between them, which reduces heat loss through the glass part of the window. It is believed that the inert gas boosts between the glasses increases the efficiency of the glass package, however, it is practically impossible to confirm this theory in practice.

- Easy to operate. Plastic, as well as all artificial materials are not whimsical to use. It does not need to be painted, process special antiseptics like a tree. All caring behind the plastic window in a wooden house comes down to its purification from dust. Plastic practically does not fade into the sun, it does not lead it from moisture, it has a significantly smaller weight in comparison with the tree.

- Price. Naturally, in comparison with a wooden window made in a handicraft workshop, metal-plastic will cost more. However, if we compare such modern wooden windows with double-glazed windows and equal accessories, then the situation is in favor of plastic.

The need to install plastic windows in a wooden house

The installation of metal-plastic windows can be much reduced by the cost of repair of the house. The fact is that in the price of the entire system, the installation takes about 30%. If we consider that most private households are at a distance from cities, then the price of installer services may increase several times due to the cost of delivering the brigade to the work site.

In addition, it is necessary to consider the comfort factor. Typically, the installation or replacement of windows is carried out at the behavior of the repair work throughout the house. With a large amount of tasks solved, it is often possible that it is often possible to prepare the workplace to the installation, and the storage of products in the warehouse will have to be paid additionally.

If you install windows with your own hands, you can more accurately disassemble window frames and boxes. Usually, employees are not too careful about their preservation, and they may still serve, for example, for the construction of the greenhouse.

Preparation of the installation site of the metal plastic window

First of all, to start installing a new window in the window opening, you need to dismantle the old window. Disassembly begins with the removal of the windows and its fittings. If there are old loops on the sash, they can jam. In this case, you can carefully pose them scrap.

Removed clouds should be taken from the place of production of works on the installation of windows so as not to be hurt about the glass installed in them.

Next, accessories from the window box are removed: the remnants of the loops, part of the decogets. If a wooden box is in good condition, it can be used as a basis for installing a metal-plastic window. In this case, it must be cleaned from old paint, dirt and dust. It is done with a damp cloth or a soft brush. If necessary, you can pass the box using medium sandpaper.

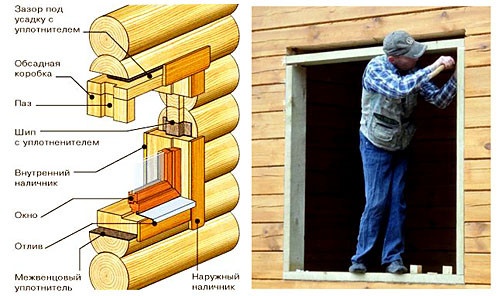

Montage of the window sill

When installing a metal-plastic window in a wooden house, a windowsill is installed first. It is he who will serve as a basis for a new window. Therefore, the windowsill must be perfectly smoothly, both in length and width. It is checked correctly setting the part with a level. In order for the windowsill had additional stiffness, it is necessary to "drown" into the side pieces of the box. For this, they are made in them at the window installation level. The windowsill is inserted into them. For its alignment on planes, substrates are used in the form of pieces of metal or fiberboard.

When the windowsill is equal, it is fixed to the box using self-tapping screws. Here you need to remember two very important points. First, the self-tapping screws are screwed only in the part of the windowsill, to which the window will be installed, and secondly, under the heads of the screws, it is necessary to put the washers under the screws. The fact is that PVC windowsill has a hollow structure and self-tapping sensor can simply sell its surface. After installing the cavity window, the windowsill is filled with mounting foam. In order to under the action of the expansion of the foam, the windowsill did not rise, an additional cargo is installed on it, which holds about a day.

Preparation of windows to installation

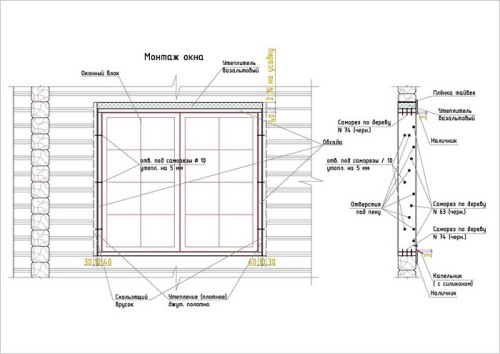

Before mounting the window it must be prepared. The first thing from the frame is removed by the glass, and the sash is removed. Before that, the handle is installed on the sash. Most metal-plastic windows are currently installed using mounting plates. They are attached with the help of self-sides to the outside of the frame, and then fixed to the window box, providing the launch of the frame. However, in wooden houses, it is advisable to mount the windows frame directly to the window to the window with the help of self-samples. For this, 8 holes are drilled in the frame (2 per side) Ø6 mm. From the inside, the diameter of the holes should be at least 10 mm so that the head of the self-pressing head freely logged inside. Self-tapping screws should be a diameter of at least 5 mm.

The removal of the movable sash does not take much time and is quite simple. It is necessary to remove the decorative caps with the upper and lower loops. Then you need to open the sash, sash and remove the locking rod from the top loop. After that, it is necessary to raise the sash to remove it from the bottom loop.

Installation of plastic windows in a wooden house

After the preparation is completed, the window is installed in place. It must be installed strictly in the middle of the window opening. For this, its width and width of the window itself measured with a roulette. The gap between the window and the window box should be approximately 10 mm on each side. It makes no sense to align the window horizontally, since this operation was previously successful with the windowsill.

Vertical lighting windows are checked with a level. It is important to set the window symmetrically with respect to the external walls so that the external slopes are the same.

In order to the window exhibited by the level did not deviate from it, it must be immobilized. It is done with the help of wooden bars that are customized in accordance with the gap between the box and the frame. They fulfill the role of a wedge. The bar is installed either for the entire length of the gap, or in places where the frame will be attached to the box. It is important that the self-taking place through it. This will give the design additional strength. However, if the house is standing on movable soils, and its seasonal movement is significantly, it is better not to have a hard binding window to the design of the house. In this case, when the wall moves, due to the deformation of the self-drawing, the window will stand still and not experiencing additional loads.

Installation of glass packs

After the installation of the window frame is completed, a rotary-folding flap and a glass dweller is a deaf half (if it comes to a two-dimensional window). Double-barker deaf sash mounted on special mounting washers. Their task is to ensure the gap between the frame and the glass, so that the latter does not cover the technological holes to remove condensate.

The glass unit is installed with gaps to the frame of at least 5 mm. Otherwise, during seasonal expansion of plastic, it can burst. Check the gaps between the double-glazing and the frame is necessary at the stage of acceptance of the finished product. If the gap is less, or it is not at all, the product is better to return the manufacturer.

After installing the glass package, it is fixed using special staps. Due to their profile spikes that should enter the appropriate groove frame, the strokes are easily fixed without the use of nails or self-tapping screws. When installing, it is necessary to easily knock on it before the appearance of a click, which means that the stroke rose into place.

Setting the sash is made in the sequence of its removal.

After installing the window, all the slots between the frame and the box are bleed by mounting foam. It is necessary to do this, both from the inside and outside. Before the final drying of the foam, the sash cannot be opened. After, the excess material is trimmed with a stationery knife.