Any equipment in the house is selected taking into account the flavor of the owner and the creation of maximum comfort in it. The bathroom is not an exception, but at the same time it is equipped with plumbing products that can last a very long time - they are usually not done during cosmetic repairs. All this time, the equipment should work without failures, so the installation of communications requires a thorough approach and the implementation of all the rules.

Content

Despite the fact that the baths in the modern market are made of a variety of materials, cast -iron products are in constant demand. This is explained by their advantages as:

- strength;

- the ability to maintain heat for a long time;

- good sound insulation;

- the weight of the bath, which gives it stability and allows you to install it both along the wall and in the center of the room.

Choosing a bath

The choice of a bath depends on the presence of sewage and water wiring. If it is prepared or there are old communications, then the product is selected taking into account their parameters.

In addition, there are other subtleties that they pay attention to when choosing a bath:

- Room design - the product is selected taking into account the interior of the room, especially since the choice of shades of enamel allows this to do this without much difficulty.

- The size of the bath must correspond to the parameters of the doorway - otherwise it will not be possible to carry it through it without risk to damage the box.

- The quality of the enamel coating - there should not be any chips or scratches on it.

- Reviews about the manufacturer of selected plumbing equipment.

Installation of a cast -iron bath - preparatory stage

Before proceeding directly to the installation of a cast -iron bath, the following preparatory measures are carried out:

- Dismantling of old equipment, if any.

- Installation of the water distribution and sewer system.

- Ram and floor decoration with tiles (article http://stroiremdoma.ru/kak-vylozhit-kafel-v-vannoj/) at the request of the owner.

Installation of a cast -iron bath

Installation of the bath is performed at the place of its placement. It is better to bring the product into the room together, however, as well as to install - its great weight when working is more likely to be a disadvantage than advantage.

When working, in addition to the bath itself, you will need:

- a set of legs - usually it goes with the product, but sometimes bought separately;

- siphon;

- drain-overflow;

- divorce key;

- level;

- screwdrivers;

- bolts;

- sealant.

Installation of legs on a cast -iron bath

- In order not to damage the enameled surface, the floor in the room is covered with a cardboard or thick plastic film.

- The product is laid on the litter sideways, the bottom to the wall, at a distance of it about 70 cm.

- On special brackets located on the bottom, using bolts and a divorce key or metal wedges, the support is installed.

The best option would be to purchase adjustable legs - they will help to set the product by level. Otherwise, the floor should have a perfectly flat surface.

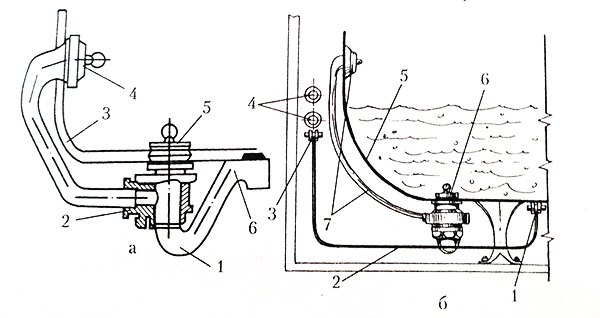

Installation of the spilling system

- Through rubber rings, the laying rings are joined by the siphon to the drain hole.

- The overflow is installed with the mandatory use of rubber gaskets and is attached to the hose to drain water.

- With the help of a coupling, the overflow pipe is attached to the siphon.

For reliability, all compounds are treated with silicone sealant.

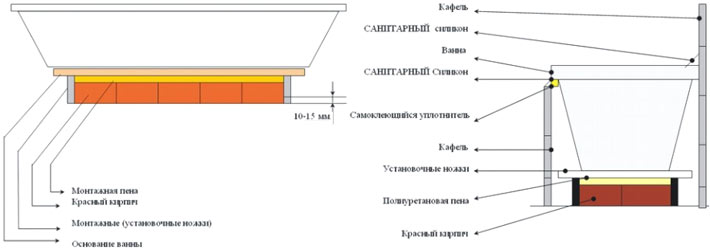

Installation of cast -iron bath on bricks

During the operation of a cast -iron bath, fasteners of the legs can be shattered. This is facilitated by the weight of the product, low -quality fasteners, etc. As a result, the structure is overwhelmed and water is not completely merged into the sewer. It is difficult to fix the situation, so often a cast -iron bath is installed on a brick frame.

There are several options for bathroom supports from bricks:

- two scaffolds;

- pillars around the perimeter of the product;

- supports in the corners or sides of the bowl;

- continuous brick platform;

- bed for the bottom of the bath.

The latter option is most often used: masonry in two bricks is done, then on its sides is added by half a brick and using the solution a recess (“bed”) for the bottom is created.

A solid platform is located between all the legs of the bath. Before laying out a brick, marking is applied to the floor with chalk or pencil.

In order for the structure to not collapse under the weight of the bath, the masonry must dry at least one day. Only then you can lay a bath on it. After installing it, brickwork is once again coated with a solution - to improve clutch.

When using any method of installing a bath on bricks, you should remember the small inclination of the product (2 cm) to the drain hole. This is done for a better water release into the sewer.

Grounding

A large number of electrical appliances installed in the bathroom are sources of danger to human health. Therefore, grounding of the bath has become a necessary element when installing it. Modern products have a special jumper for fastening the wire.

For grounding, a long isolated cable (2 m or more) with a section of 6 kV/mm is used. The other end of the wire is attached to a special distributor or metal tap pipe.

Installation of a cast -iron bath

- After two legs are installed, the bath is carefully turned over and put on them.

- A reliable support is placed under the other side, and the remaining supports are attached.

- The bath is leveled by level using screws in adjustable legs.

- Fixing nuts are tightened.

- A flexible hose is connected to the sewage system.

- The gap between the wall and the bathroom is filled with a silicone sealant.

- The control of the bath is carried out: the tightness of the structure and the correct installation are checked.

Alignment is carried out from one side and end of the product. If the bath is near the wall, then the gap from it should be 1-2 mm.

Installation of a cast -iron bath, video:

A few tips

- If the floor in the room is not too durable, then under the supports are lining of metal or plastic with a thickness of at least 5 mm.

- Thin metal legs, which sometimes come in the kit, require the installation of additional supports. Only in this case, the fastening of the cast -iron bath will be reliable.

- For the normal operation of the siphon, the distance from the floor to the bottom of the product should be from 14.5 cm.

- The cast -iron bathtub will be more reliable if you use the combined installation method - on the legs and brick support.

- The metal drain grill of the siphon is more reliable than plastic - it is more rigid and more tightly pressing the rubber rings.