Every year, all new and new materials appear in construction stores that can simplify the repair process in an apartment or home. Such materials include 3D panels. They recently appeared in the construction market, but have already managed to gain tremendous popularity. Thanks to the peculiarities of 3D plaster panels, you can repair in a short time, not exceeding the planned cost estimate, and at the same time get a stunning appearance of the renovated room. Next, we will tell you more about the characteristics of this material, as well as how the installation of 3D panels on the wall is carried out.

Content

Advantages and disadvantages of the panels with a three-dimensional effect

Creation of 3D compositions as decoration of walls and ceilings is not a new idea. However, initially images with a three-dimensional effect were created with great difficulty, as well as through the use of various shapes and layouts. At the same time, it was not always possible to depict the bulk composition on the surface of the desired form and size. Today, this process is much easier, because new 3D panels have appeared. On their surface, a concrete volume pattern is depicted, due to which, placing the panel in a certain sequence on the wall or ceiling, you can get a beautiful three-dimensional pattern.

Advantages of a three-dimensional effect panels:

- Easy installation. 3D plates can be easily and easy to fix on the surface of the wall or ceiling with the help of construction glue. At the same time, there is no need to pre-align the wall and use of expensive plaster.

- Universality of the material. The three-dimensional effect panels can be used as the main coating of the entire surface or its individual elements, because 3D plates are successfully combined in the composition and with other materials.

- The sphere of using 3D panels is quite extensive. The plates data are suitable for lining any type of surface: walls, ceiling, furniture facades, etc. At the same time, they can be pasted on the surface from any material, for example, from concrete, brick, drywall, wood.

- With the help of 3D plates you can hide irregularities and other surface defects.

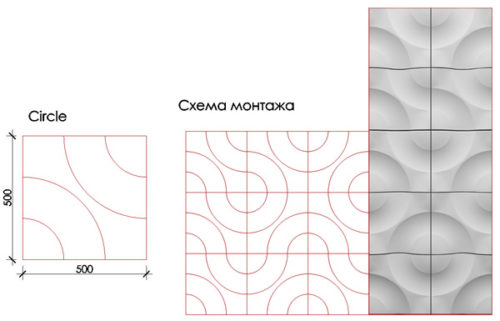

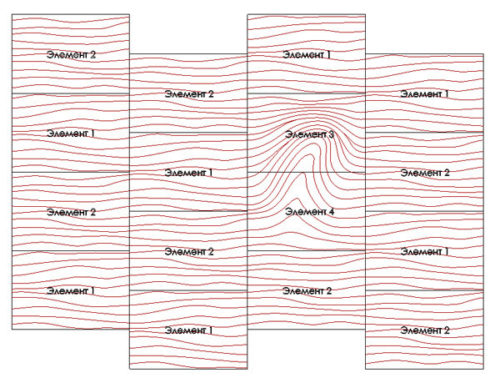

- Beautiful appearance. On the surface of the 3D plates, any ornament can be depicted, even the most complex shape. At the same time, the panels can be collected according to the type "Puzzle", as a result of which, they collected together, will be part of a large whole composition. With the successful use of this material, you can create a truly original interior design of 3D panels in almost any room.

- Wearness and long service life. With the proper laying of this material, using all technological nuances of the process, 3D plates can serve quite a long time. 3D plaster panels are not deformed under the influence of intensive sunlight and moisture drops.

- Good thermal insulation properties. Thanks to these qualities of the three-dimensional effect panel, you can use for the insulation of the room.

- Excellent soundproofing properties. In addition to thermal insulation qualities, 3D plates have sound insulation. They can be used to reduce indoor noise. Felt acoustic stoves have the highest sound insulation qualities. They are used even when closing recording studios.

Disadvantages of the panels with a three-dimensional effect:

- The need for regular cleaning of premises, the walls of which are lined with 3D plates. Since 3D panels have a relief surface, dust often accumulates on it, as a result of which the material acquires a non-dimensional view. This drawback is solved with the help of a systematic cleaning of dust on relief surfaces.

- The complexity of designer design. In order for the room, lined with 3D plates, did not have a boring and monotonous appearance, it is necessary to threaten the designer style of the decor.

Recommendations for the choice of 3D panels

Before purchasing material, read the following guidelines for the choice of 3D panels:

- Try not to acquire 3D "in the blind", it concerns and online sales. After all, it is only a person who estimates the appearance and quality of the product, you can buy that material that will ideally be suitable for facing your room.

- Do not acquire massive and large-sized plates, because they are pretty impractical and through a small amount of time can cause the wall collapse. It is better to give preference to a "lightweight" version of the plates that weigh a little and at the same time are quite practical.

- Check the quality of the edges of the purchased panels. It is important that the edges of the plates when docked with each other formed the correct geometric shape.

- When buying, specify the composition of the purchased panels. It is important that they do not have harmful chemical compositions and formaldehydes.

Types of 3D panels

There are several varieties of 3D panels:

- Wooden (genuine wood, plywood or MDF). The base for such plates serves an array of wood, plywood or MDF. If we are talking about the last two types of plates, then a decorative film is placed on top of the main layer. It is capable of imitating various expensive wood. Such panels have a relatively short service life. As for products from a natural tree, they are covered with a protective layer of varnish.

- Metal. The base for these panels is aluminum, steel or copper plates. They are covered by protective compositions. Unlike wooden plates, metal serve for a longer time. However, they are, respectively, more expensive.

- Gypsum. The most popular type of plates. Refers to environmentally friendly types of material. It has an acceptable cost. It serves quite a long time.

- Glass. The basis of such plates is tempered glass. In the process of processing on the surface of such panels, beautiful colorful faces appear, which give plates a beautiful and luxurious look. The material has a fairly high price.

- Plates based on cane cake. Their cost is quite low. At the same time, such plates have a good quality.

- Felt panels. As mentioned above, they have excellent noise insulating properties. An embossed pattern can be applied to the textile basis.

- Decorative acrylic. Such plates have aesthetically attractive appearance. Inside the transparent base, a beautiful decorative layer is usually imitating the foliage of trees, flowers, marine seashells or others.

- Plates made of genuine leather. Elegant and luxurious type of material capable of issuing a special charm. It has a fairly high price, while it is characterized by excellent quality.

- Stone plates. The basis of such a material is an artificial stone, which, with competent processing, has a rather attractive appearance.

Installation of the panels with a three-dimensional effect

For mounting panels with a three-dimensional effect on a plaster basis, the following tools and materials will be required:

- Glue designed for sticking of gypsum materials.

- Marker - for marking.

- Roulette - for measurements.

- Level - to verify the correct installation of the plates.

- Water container.

- Pieces of textiles.

- Knife - for cutting material.

- Sealant.

- Primer mixture.

- Sandpaper.

The procedure for mounting the panels with a three-dimensional effect on a plaster basis:

- At the first stage, the calculation of materials for the installation of 3D panels in accordance with the size of the repaired room is carried out.

- Next, work is performed on the preparation of the working surface. So, thanks to 3D panels you can hide small surface defects. However, if irregularities, cracks, damage or too large, they should be eliminated by applying starting putty. Then you need to give time so that the putty mixture is frozen and dried.

- Then it is necessary to clean the working surface from the remnants of the construction trash, dirt and dust. If the walls were painted before this, then the paint should be considered with the help of sandpaper, since the gripboard with too smooth surface will be minimal.

- Next, 3D panels must be covered with a layer of primer. It will help protect the material from penetration into its structure of excessive moisture. Further installation work should be carried out only when the primer is completely dried.

- Then prepare the adhesive mixture and apply it to the opposite side of the plate. Next, the 3D panel presses to the surface. At the same time, the remnants of the adhesive composition, which made the edges of the plate, are cleaned with a dry clean rag.

- The correct installation of 3D panels check with a construction level. The first row of plates should be lowered strictly horizontally, and it is already necessary to start laying the next row. To avoid errors when installing 3D panels, timely check the quality of the clutch of the material with the working surface and the correct installation of the rows of plates.

- Try the plates to lay so that the sliced \u200b\u200bpieces remain at the bottom of the wall or in the corners. At the same time, glue the panels so that there are minimal gaps between them, otherwise the construction of a three-dimensional pattern on the wall can be disturbed.

- The seams that were formed during the styling of the plates should be filled with a primer mixture. Excess primer is removed using a dry clean cloth.

- Further, it is necessary to wait for a complete drying of the primer mixture, and then depart the joints between the stoves. If it is planned to further paint 3D panels, then they are previously coated with a protective primer layer.