For decades in Europe, original materials have been actively used as flooring. It is worth noting that new materials are not always expensive. It is not so rare in construction stores that you can find far from the most ordinary products, which looks attractive, and is inexpensive.

Content

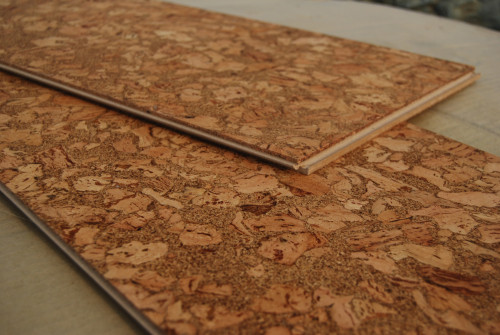

It makes sense to say that in a large number of countries, cork floors have become a real hit. Not only is it a comfortable coating, it is also very inexpensive. I must say right away that this is only a small part of the positive aspects of the material. To date, manufacturers of such building resources use all possible resources so that the coating will receive as many positive parties as possible. This applies not only to the strength and durability of the material, but also to its appearance.

Features of the use of cork materials

Camping coatings are considered universal. However, you can find a variety of variations on sale. Often, cork coatings are characterized by density. Many are used to the fact that this material is not particularly durable, however, in construction, cork blanks of large thickness and the highest strength are used. At home, this allows you to use the material without any problems for decades.

As coatings, cork material can be found in the form of tiles, which without any problems fit on the surface. You can also find a cork parquet that has much in common with the original coating. Of course, the second option is much more expensive than the first, however, the use of a particular option depends on specific conditions.

Parquet often fits in the central rooms of the dwelling, where it is necessary to create a rich and cozy atmosphere. Also, laying a cork parquet is limited to very simple actions, since often the material has already passed the necessary surface treatment. Cheaper options for cork parquet do not have the desired initial finish.

Most often, experts recommend purchasing parquet without finishing. After the material is laid on the floor surface, you can carry out full -fledged processing, while you can be sure that we will get a positive result.

You can also be sure that the unprocessed surface of the floor will not be damaged during transportation and long -term storage.

If we are talking about the factory processing of the material, then attention should be focused on the price of products. Most often, it will be cheaper to process the surface of the parquet yourself using the simplest tools.

Laying a cork floor

Most of the cork materials that are currently available for purchase in construction stores are very simple. Companies producing such products do everything possible to simplify any manipulations with flooring.

If we are talking about laying ordinary cork tiles, which are almost similar to ceramic material, then their installation occurs through the use of glue. Parts of the material are simply glued to the floor, which must first be cleaned and washed.

For these measures, contact glue is used, which glorifies the material reliably and on both sides. First, glue is applied to the back of the cork material, and then on the very surface of the floor. The layer of the binder material should be relatively thin, and each laid tile is placed at the same level.

After applying glue to the tile, you need to wait 20-30 minutes before pressing it to the floor. Application of glue occurs using a brush or roller. Of course, it is impossible to allow the presence of passes on the back of the material, everything must be carried out efficiently.

It is also worth saying that situations often occur when there is a need to replace a particular part of the cork coating. Of course, this is possible, however, this event needs to be carried out efficiently without damaging the neighboring cork elements.

There is a council that is able to significantly simplify repair work. People who lay cork plates first create markings, which allows you to immediately understand exactly where the material will be located, as well as where you need to cut part of the purchased products.

Features of laying cork parquet

Despite the fact that the cork parquet is almost similar to classic parquet, the original material has some features that you need to know about. There are three layers corqueter: the first is the fibrous base, the second is cork, and the third layer is compensatory, which perfectly copes with all loads to the surface.

Unlike cork plates, which are also very popular, the parquet has a large thickness (up to 11 mm). Accordingly, this creates some problems when repairing the surface.

The main advantage of cork parquet is the lack of the need to use additional insulating layers. Thus, it is on the basis of a “floating” method that cork material is laid.

The installation process is quite simple, and it consists in the gradual laying of the rows of parquet. After the first strip of material, the next cork element must be attached with a certain inclination, which should perfectly enter the groove. If everything went well, then during this process you can hear a characteristic “click”. Next, you need to knock out the strip of material along the mount with a small kiyanka.

Other features of cork material

It should be understood that cork material is far from universal. It is necessary to focus on the fact that it is advisable not to use it in rooms with high humidity. At the same time, in construction stores you can find cork coatings saturated with moisture -resistant substances, so that with moderate humidity and this material can be used in non -favorable conditions.