Drywall has always been particularly popular among the entire assortment of finishing materials. With its help, you can create surfaces of any geometry and complexity, and the work takes a minimum of effort and time. But in order to get the perfect result, you need to learn how to make even angles from drywall. This is necessary not only from aesthetic, but also from a practical point of view. Today we will talk about how to make an angle of drywall with your own hands.

Content

The need to create even angles

When lining the walls with drywall or the creation of individual structures, for example, a box or partition, it is very important to correctly mount the corners. Otherwise, the work will look at least unattractive. An uneven or weak angle also will lead To the fact that the building will quickly fall apart or deform. Special installation technology provides additional fasteners. They enhance the strength of the entire structure and allow it to withstand various loads.

If you make the walls of the walls with a drywall, but do not pay enough attention to the corners, then very quickly, cracks will appear in the places of intersection of sheets. Below we will describe in detail several technologies for creating plasterboard corners, which are applicable for the construction of niches, boxes, walls and even cabinets.

Distinguish between the external and inner angle of drywall, the technology for creating which has its own characteristics. Let us consider in more detail each of them.

Inner angle of drywall

If you make the walls, make a cabinet or niche, you just can not do without arranging neat internal corners. Make them enough just, the main thing is to follow the instructions and stock up on the necessary building materials. Fortunately, they will need them a little.

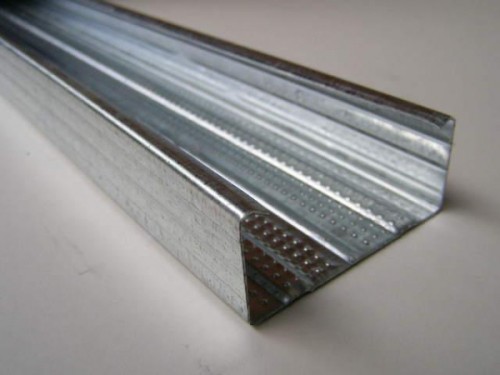

To work, you need to make a metal frame from a rack profile. Different types of profile are selected depending on the functional purpose and load on the future design. So, to mount the strong internal corners of the ceiling made of drywall, it is necessary to purchase rack profiles Ps Or CD. It is important to choose a quality profile, if you do not want it to deform, and over time, cracks spread along the wall.

For installation, you will need to combine two segments of the profile with metal screws about 90 mm long. Install self -tapping screws in step 25 —30 cm no more for the design to be stable. The distance between the mounts is more dependent on how much tough is the base, and for internal drywall angles you need the maximum rigidityOtherwise, they fall off under their own weight.

More One mandatory requirement for installing profiles in the inner angles is the presence of a perfectly even and smooth surface. Fortunately, drywall itself is perfect in this regard and does not need additional equalization.

How to make an angle from a profile for drywall:

- Take a couple of rack PS profiles and mark them with a marker in places of future mounts.

- Lay the profiles perpendicular to each other so that one of them is tightly adjacent to the front of the second. The result should be a right angle.

- Drill with a drill with a nozzle of suitable diameter through holes in the intended places.

- Connect the profiles with self -tapping screws.

- On the perimeter of the angle, set the guide profile Mon and insert the resulting hard corner.

- Fix the angle in the guide profile with self -tapping screws.

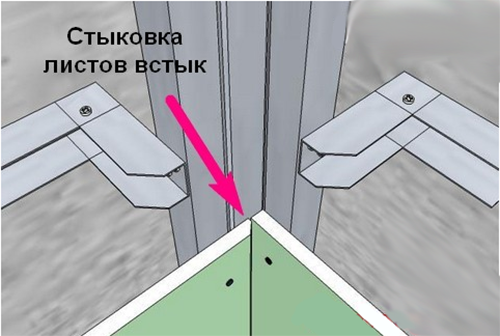

- Pick the drywall sheets. In the corners, it is best to install plates with "native" edges sharpened at 45 ° to seam He went out neat.

- If the plasterboard sheets are already cut off, use a knife and sandpaper to remove the chamfer under 45 °.

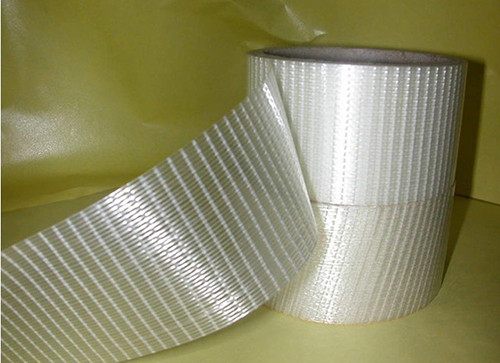

- Stick the net to the joint strobi, smearing a little there puttyAnd press the corner spatula. Thus Go throughout the area of \u200b\u200bthe inner corner.

External angle of drywall

To make the outer angle of walls of drywall, it is necessary to act a little differently. To do this, you do not need to create a separate connecting frame, since the profiles on the outside will not be attached. The arrangement of external angles involves the use of two metal or plastic perforated profiles, which are simply put on both sides of the wall (it is better to choose metal, since they are more durable and durable).

During the fixation of drywall, make sure that it is with uncircumcised edges. Otherwise, you will need to remove the chamfer to a depth of ½ of the thickness of the sheet. To attach rack profiles to perimeter Use metal screws.

When you attach the profile, the clutch area putty With a plasterboard wall will be increased, which will create an additional guarantee of strength and durability of the finish. Keep in mind that during the fixation of sheets to the angular frame profiles, the distance between the self -tapping screws should be reduced. It will also be unsuitable take care of additional sound insulation of the walls, especially if speech goes About repair in a city apartment. Hypsum plasters itself slightly protects against noise, so the soundproofing material should be laid between the frame and sheets until they are fixed.

More One feature of the design of the outer angles of drywall is that an empty space occurs between the sheet and the overlap. It can idle idle Or benefit by hiding various communications and wires.

Important: a chamfer under 45 ° must be removed without fail. This is necessary so that the metal corner does not stick out and fit well in the created deepening. Also at putty seams of the clutch area of \u200b\u200bthe solution with the surface are becoming larger.

How to make an external angle of drywall with your own hands:

- Prepare the necessary materials and tools: the construction rule, roulette, level, screws, gypsum -based glue, perforated metal profile.

- Check the corner profile for straight line over the entire length. Since it is made of flexible material, he could bent during transportation. If the slightest bend is detected, it makes no sense to align it - it is better to postpone this material for more rough work.

- Frank the length of the angle with a roulette. The corner profile should be shorter than the length of the angle by 2 —5 mm.

- Attach the profile to the surface of the angle and tightly press along the entire length by the construction rule, so that in the interval there was no remaining Not the slightest gaps.

- Without releasing the rules, attach the level and control the verticality of the corner. In case of deviation from the norm, press or release it.

- Fix the corner in strictly perpendicular paul position And attach it with screws to the drywall wall. Only after the profile reliable fixed, you can remove the rule.

- Prepare gypsum glue, diluting it to the consistency of thick mastic. Apply it spatulas on the shelves of the corner profile with a rather thick layer. It is important that the glue fills all the voids between the profile and drywall sheets.

- Wait a bit to glue started Grab and then twist the screws and smear the holes they left. Remove the excess glue with a spatula until it froze, so that the corners are even and neat. To do this zesta the spatula is strictly perpendicular to the corner and spend in one motion top down, "Cutting off" the glue.

When the glue dries, sand the surface thoroughly. After that, you can proceed to the primer, putty and decorative decoration.

Methods of fastening drywall

The method of fastening drywall when creating angles directly depends on the nature of the device of this angle. So, if you are shearing a frame in one sheet, then the adjacent elements of the outer corner will seem to be on each other. For this reason, the end part of the drywall in the corner should be cut to the gypsum itself (it is necessary to completely clean the cardboard shell). If this is not done, the angle will be much more difficult to putty.

When installing internal angles, drywall is also recommended to be cleaned of a cardboard layer. If the docking is T-shaped, the end parts are cut under angle 45° for more comfortable putty.

If you are shearing a frame in two sheets of drywall, then the elements will certainly shift.

Finishing of drywall angles

If you dealt with the installation, then the finish of the angles of drywall will seem to you rod business. Even one who has never worked with putty mixtures, can easily cope with the decoration of the drywall surface. But before picking up a spatula, structure and angles, it is necessary to cover with an adhesive primer of deep penetration. She will protect the material from moisture from putty And he will give him greater strength.

The primers of the German manufacturer Knauf are very popular, which can be 100%confident, albeit at a fairly high cost. You can apply the soil with a roller or a wide building brush, carefully processing every centimeter of the surface. When drywall dries, you can proceed to putty.

How to putty drywall angles:

- First, apply putty to the recesses left by self -tapping screws in the corners, and then proceed to the processing of seams and joints.

- When working at the junctions, use a reinforcing grid, cutting her to pieces and gluing on top of the connection of the sheets, including in the corners. You can glue the grid on a regular construction PVA.

- After the glue dries, apply the layer putty And align it as much as possible. Do not immediately try to get a perfectly smooth surface - even with professionals this it turns out not always. When decorating the outer angles, first check the evenness using the level and only then proceed to grinding. If a deviation is detected, apply to the right place more A little putty.

- After drying putty In the corners of drywall, sand the surface with sandpaper of small grain grain. Thus, you will get rid of pauls And Bugorkov.

To summarize, we suggest you familiarize yourself with the useful training video about the angles of drywall and the specifics of their putty:

Joints In structures from gypsocaton are the most vulnerable component. Due to the high fragility of the material, it can be very difficult to obtain perfect joint of angles. At the same time, corners are the most noticeable part of any structure, where bumps and defects are immediately striking. That is why it is important to use direct metal profiles and not spare self -tapping screws for their fastening. This is the only way to get neat internal and external angles in drywall buildings.