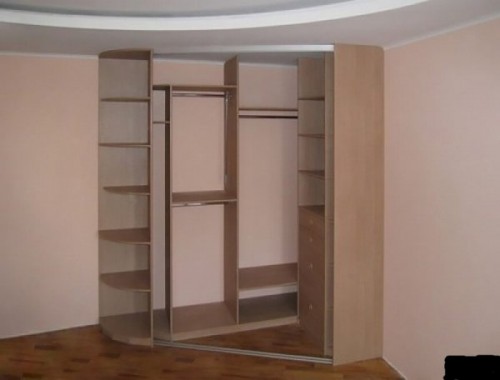

Often people complain about the lack of space in a small apartment, but meanwhile the corners in the hallway, in the kitchen, and in the rooms are empty. Having built a cabinet in the corner, you can solve the problem with “extra” things that have nowhere to attach in one fell swoop. The article will talk about corner cabinets, about their advantages and with your own hands.

Content

Classification of corner cabinets by configuration

In the configuration, corner cabinets are:

- triangular;

- Mr.

- trapezoidal;

- 5-set.

The latter belong to the classic. They fit well between furniture.

DIY corner cabinet

Consider the process of manufacturing an angular wardrobe.

To begin with, we will carry out preparatory work:

- We compose a diagram of the corner cabinet.

- We determine how much material you need to order.

- We will prepare the material and tool. And the following will be needed:

- Chipboard, MDF or board;

- dowel;

- glue;

- self -tapping screws;

- mirror;

- accessories;

- the videos are of high quality, otherwise they will quickly fail;

- profile is better than steel.

4. We are stocked up with the following tool:

- perforator;

- drill;

- roulette;

- level;

- hammer;

- hacksaw;

It is more reasonable to open the details of the cabinet in the workshop or right in the store, and leave only the assembly for yourself. This is very troublesome and laborious.

How to choose the dimensions of the cabinet

For the angular cabinet, the dimensions are determined depending on the area on which it is planned to assemble it, but still one should adhere to some general recommendations:

- The minimum width of the compartment, where it is planned to store outerwear - 0.8 m.

- The height, convenient for the location of raincoats, fur coats, coats, at least 1.4 m. Here it is necessary to take into account the growth of family members so that they can freely reach Rigel.

- The space inside the cabinet is used more rationally if the crossbar is placed along the width of the section.

It will be better to navigate the sizes for the approximate diagram of the corner cabinet:

We collect a closet

The assembly of the corner cabinet is carried out in the following sequence:

- We mount steel corners in places where the side walls of the cabinet will subsequently attach to the ceiling, walls and floor.

- We use the level in the process, otherwise it is easy to allow the skewing of the door.

- We collect a frame from ready -made details. If the performers came across professional, then there will be no problems.

- We fasten the videos on the door.

- We mount the guides.

- Install the door.

It remains to equip the closet inside and install accessories:

- set the partitions;

- we fix the hangers, shelves, mirror;

- we fasten the pens.

Everything, a functional and convenient cabinet for your service.

Cornflow for kitchen

The kitchen is a place where the issue of organizing small spaces is especially acute. Consider 2 examples of the design of the corner kitchen cabinet. To obtain a quality product, the assembly of the corner cabinet is performed based on the following reasons:

- with your own hands to order parts of the kitchen corner cabinet, drawings will be needed;

- we will not cut nothing on our own. Experts can better observe geometry;

- we will perform measurements for ordering workpieces only after we level the floor and ceiling, smooth the irregularities on the wall, otherwise the cabinet may not fit.

- we will pick up the fittings of high -quality, although it costs more, but quite justifies itself.

In the design of the corner kitchen cabinet there are 2 types of connection:

- at an angle of 90 degrees. Under it, it is possible to install a standard countertop;

- at an angle of 45 degrees. Under this type of corner cabinet, a corner sink is installed.

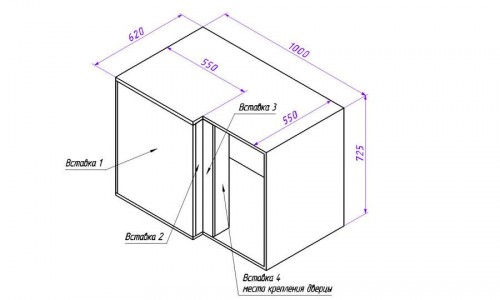

The difference between the corner structure with a connection at an angle of 90 degrees from the standard

In the corners there are the following design features:

- the presence of additional elements in the form of inserts that tighten the boxes among themselves and partially are a facade;

- the presence of ledges in the upper and lower part.

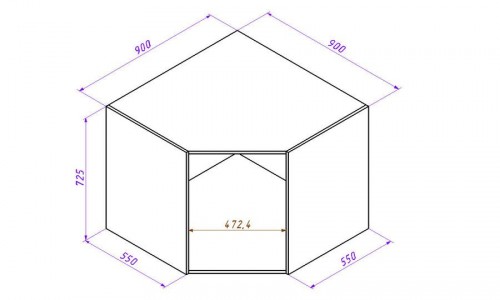

Features of the corner cabinet connected at an angle of 45 degrees

This type of cabinet has 2 essential features:

- Dimensions. So, if the lower cabinet has a width of 600 mm, then the hinged - 900x900.

- The location of the parts. If in the standard cabinet the lateral elements are located between the upper and lower, then here, on the contrary, the upper and lower between the side. It will not work in any other way, because It will not be possible to install the facade.

Under such a corner cabinet and the countertop has the same shape.

DIY gypsum cardboard

For the manufacture of gypsum plasterboard of the corner cabinet with your own hands, drawings are necessary in the first place. For this:

- we determine the place where the cabinet will be located;

- we perform a detailed scheme on which we indicate the dimensions and sizes of all parts, even very small;

- we determine with the quantity and mark where there will be sliding boxes, suspended baskets, doors;

- indicate the thickness of the material. Without this, accurate calculations are impossible;

- we make a specification of all the elements included in the design of the cabinet.

A photo in special catalogs will help in choosing a corner cabinet design. There is an opportunity to download ready -made drawings of cabinets on the Internet. And after watching this video, you will learn how to design a corner cabinet yourself using special programs:

We mount the frame

We perform markings on the ceiling at the installation site, the floor before starting work on the installation of the corner cabinet.

- We mark where the lamps are provided, unless, of course, it is planned to install them.

- We glue the rubber shock -absorbing insulation from the side, which will fall on the base on the base.

- We fasten the guides along the marking lines. As fasteners, we use dowel-gvo.

- We fix the straight suspensions on the wall by preliminary marking. Choose fasteners depending on the material of the base. If it is a brick or concrete, then a dowel-gvo is needed, for a tree we select nails or screws, for aerated concrete or hollow brick-special dowels that have spacer mustache and transverse notch. It depends on the right choice how strong the design will turn out.

- We insert vertical racks into the guide and fix them with suspensions using short screws with a press shame as fasteners.

- We mount the stiffeners between rack profiles. The more there are, the more stable the construction. Especially need to strengthen the place where the boxes, shelves will be installed.

Note: It is possible to replace the purchased metal profiles with wooden rails, only the wood is needed absolutely dry, otherwise it will shrink and the cabinet is deformed.

Frame sheathing

In order to perform the skin:

- We cut the blanks made of drywall with a wall thickness 1.25 cm with an electric jigsaw or hacksaw.

- We process the edges with a crum ground.

- We arrange the finished elements in the places intended for them and first screw them with self -tapping screws.

- We fasten the sheets finally, placing screws with a step of 200 mm. Self -tapping hats are drowned by 1 mm.

- We install furniture corners in places where the shelves will be and lay on them shelves made of two, glued with each other, sheets.

- We mount barbells, lamps.

- We make measurements again and order the doors. It is not worth it before, because The actual dimensions may not coincide with the original.

Finishing the corner cabinet

So with your own hands is made, it remains to ennoble it. For what:

- we primer all surfaces both external and internal;

- we seal the joints with gypsum plaster;

- we glue the certifying tape;

- install the painting corners on the corners;

- we apply a layer of putty, let it dry and grind, and then put down again;

- we primer, and when everything dries, we perform the final finish. It can be anything, from painting to mirrors, and in the bathroom and tiles are faced.