TV is an indispensable attribute of any home. Modern models are installed on the cabinet or hung on the wall - it all depends on the interior of the room. But the presence of special furniture is required in any case. Related devices and equipment should be placed near the TV. And the collection of discs usually takes up a lot of space. A do -it -yourself television cabinet will fit perfectly into the interior, as it will be made by the owner of the house in full accordance with his taste.

Content

Tumbs for woods made

Materials

The following materials are used for the manufacture of a wooden cabinet:

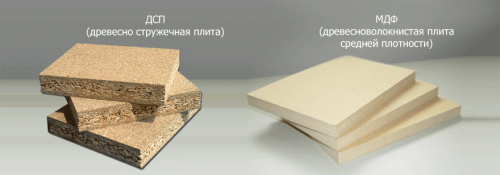

1. DSP - the most popular material for the manufacture of furniture. This is explained by its properties as:

- a large selection of shades;

- easy in processing;

- available price.

2. MDF - wood -fiber plate is also perfect for making a bedspread for a TV. It will cost more than chipboard, but it will last longer. In addition, MDF has its advantages:

- environmental friendliness;

- light weight;

- homogeneous structure.

3. Natural wood is more complex in processing and has a fairly high cost. The undeniable advantages of the material, its appearance allow you to create beautiful, rich furniture. The wood is different:

- resistance to environmental impact;

- strength;

- environmental friendliness;

- durability.

Preparation for work

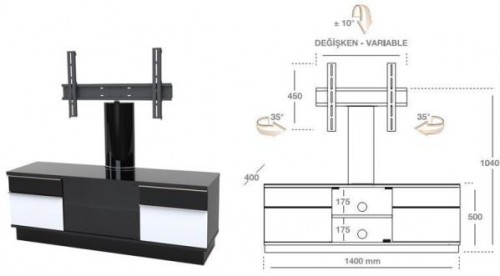

First of all, they are determined with the place for the cabinet for TV and its size. The configuration of the product depends on the parameters of the TV and the equipment under which it is intended. Its appearance should be combined with the atmosphere of the room and correspond to its style.

Then a drawing of the cabinet for a TV is compiled, which indicates the size of the parts and their configuration.

Based on the data of the scheme, a detail is carried out indicating the number of elements and their parameters, for example:

- cover, bottom and shelf - 3 pcs. (1600x400 mm);

- racks - 4 pcs. (100x382 mm);

- facades - 2 pcs. (136x458 mm);

- sideins - 2 pcs. (142x400 mm);

- the middle stand is 1 pc. (142x382 mm);

- the back bar - 1 pc. (100x1600 mm), etc.

From the dimensions, it is clear that the result will be a long cabinet for TV, but it all depends on the desire of the master, the size of the equipment and the availability of free space in the room.

Under a small TV, it’s enough to make a small “stand” with a minimum of details.

Tumbling from chipboard

For the manufacture of a cabinet from chipboard, you will need:

Materials

- DSP-usually use a sheet thickness 16-18 mm;

- 3-mm plywood;

- pVC edge;

- confirmation;

- screws;

- plastic caps;

- telescopic guides;

- accessories;

- putty;

- nitro -painting.

If the doors are planned to be made transparent, then glass is purchased.

Tools

- electrician;

- drill;

- drill;

- screwdriver;

- screwdriver;

- sensor tools.

Cut the products

- In accordance with the drawing, all sizes of parts are transferred to Watman and patterns are drawn.

- The pattern is applied to the chipboard and fixed with clamps.

- With the help of a jigsaw, elements of the cabinet are carefully cut.

- The edges of the parts are polished.

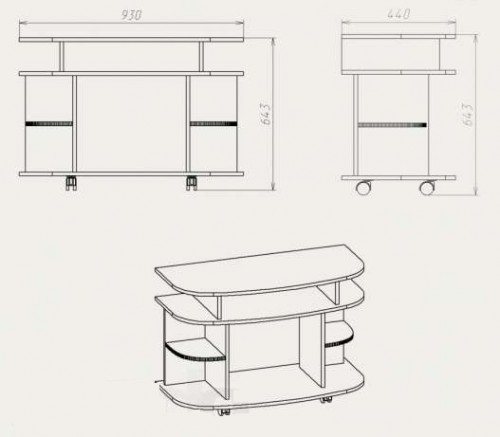

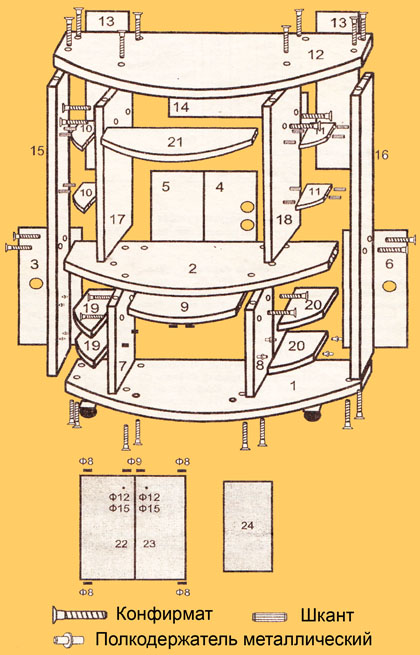

Tumbling for TV - Assembly

1. The details of the frame are connected. At the same time, several options are used:

- holes are drilled, and the regiment sits on dadies;

- consolidation of parts is carried out using self -tapping screws or confirmations. The holes of the screws are spilled into the canvas and then masked by stickers;

- gather parts for furniture eccentric screeds. But at the same time, you need to have work skills - with inaccurate drilling and improper calculation of the depth, the fastener hole can be through.

2. Shelves and doors are installed.

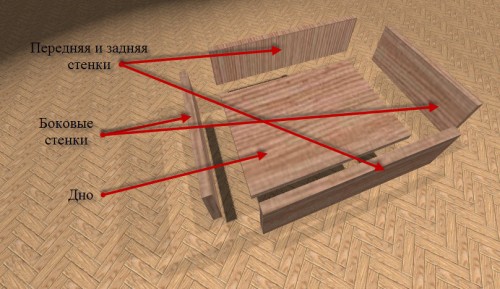

3. The boxes are collected according to the following scheme:

- the double thickness of the side walls of the “tray” and the width of the guides are taken away from the inner width of the cabinet - thus the size of the rear and front wall is calculated;

- the height of the structure is arbitrary;

- the depth of the box depends on the same parameter of the cabinet beyond the thickness of the thickness of its walls;

- the bottom of the structure is most often made of an organ - the material is cut out in size of the box;

- the facade closes both sidewalls.

4. Furniture is fixed.

5. The legs are installed.

6. The surface of the structure is treated with sandpaper and putty is applied to two layers.

7. After the material dries, the details are again clicked.

8. The cabinet is painted with nitro.

The resulting design is not necessary to paint - it can be covered with veneer or glued with a film.

We pay attention

In the manufacture of a TV for TV, you should pay attention to some points:

- On the back wall of the product, holes for electric cords are necessarily made.

- Large TVs are usually located on low cabinets and vice versa - small models look better on higher stands. The optimal height of the structure is 50 cm from the floor.

- With a large severity of the equipment, instead of legs, it is better to make a stand made of chipboard or just install the cabinet on a flat surface.

- If the product lid is made in the thickened version, it will look more solid.

- Stiffer ribs should be located at least every 400 mm of the length of the cabinet.

- In a small room, an ideal option would be a corner for a TV - it will take up very little space.

Glass cabinet

The cabinet made of glass looks very elegant - not without reason such furniture is becoming more and more popular.

There are two options for creating such a design with your own hands:

- Buy a set of parts of a glass stand in a furniture warehouse. The catalogs offer a wide variety of cabinet for TV with photos, the price of such structures is quite affordable. Independent work will be in the assembly of the product. The plus of this option is high -quality glass processing and other elements of the cabinet. At home, it is difficult to achieve such a result.

- Make all the details of the glass cabinet yourself.

When choosing the second option, some skills in working with glass will be required.

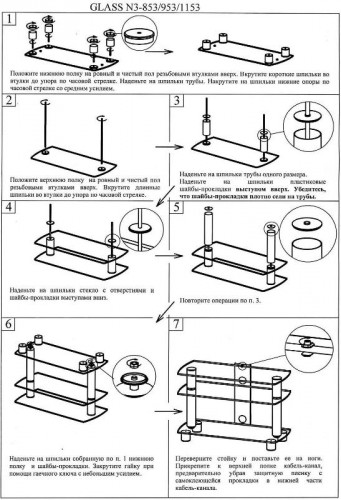

How to make a glass cabinet

The order of work in the manufacture of a rectangular structure with a size of 100x40 cm:

1. Materials are purchased:

- 4 studs with a thread M-10 and Ø 10 mm;

- chrome pipe Ø 50 mm;

- 16 plastic rings - gap nodes;

- silicone glue-mix.

2. are determined with the size and configuration of the product and its diagram is drawn.

3. All parts made of glass with a thickness of 0.5 to 1 cm are ordered in the workshop (depending on the upcoming load on the cabinet).

4. In a turning workshop, 4 upper stainless steel or aluminum supports are performed.

5. Using a grinder, the pipe is strictly perpendicular to cut into the segments:

- 150 mm - 4 pcs.;

- 550 mm - 4 pcs.;

- 50 mm - 4 pcs.

6. The edges of the parts are processed by a file.

7. Maily on the glass and the places of gluing upper supports are degreased.

8. A layer of transparent silicone glue is applied and, using a clamp, the parts are pressed to the glass.

9. After drying, the remnants of the mixture are removed.

10. In the second and third canvas for the stud, holes are drilled. This is done using a drill and cylindrical crowns with diamond spraying for glass. The holes are best drunk according to a pre -prepared template.

11. The upper canvas of the cabinet with supports is laid on a flat surface. Studs are screwed into their threaded holes, on which the pipe segment (150 mm) is then put on.

12. Next, the assembly is in this order:

- glass;

- pipe - 550 mm;

- glass;

- pipe - 50 mm.

13. Between glass and pipes on both sides, the gap nodes are necessarily installed.

14. The lower supports are wound on the studs and carefully, without unnecessary efforts, are tightened.

All the details of the structure can not be sought shops, but ordered in the workshop.

Such a television cabinet, the price of which is much lower compared to the finished product, will decorate the interior and can withstand a considerable load.