An elegant toilet table in the bedroom is the desired and practical element of furniture. To make an original and authentic table for the vital needs of a woman is not as difficult as it might seem.

Content

The toilet table in the bedroom should harmoniously combine in style and color with another furniture and interior. In order for it to become a really functional and useful object, make a toilet table with a mirror.

Tool and materials for work

- Drill, and better a screwdriver with a 10 mm cartridge and a set of bit for assembling furniture and drill.

- Electric with a canvas for chipboard. In many stores there is a paid service for cutting chipboard.

- A combined reverse screwdriver with a set of bit, a hexagonal key for confirmation.

- Marker and an awl for marking, roulette, ruler and carpentry corner.

- An iron or a construction hair dryer for welding a flat end tape. Silicone glue for "P" is a figurative profile and the flexible profile itself.

Fittings and fasteners for assembling the toilet table

- The furniture stores have a large selection of pens for boxes and facade doors.

- You will need loops, awnings and roller guides for drawers.

- To assemble the crushed elements of the toilet table from the chipboard, purchase confirmation (5x70), wood screws (4x25 and 4x16).

- Plastic mounts or special glue for fastening mirrors, metal corners, PVA glue, plastic decorative plugs for confirmation for the main color of chipboard.

Drawing and marking of the toilet table with a mirror

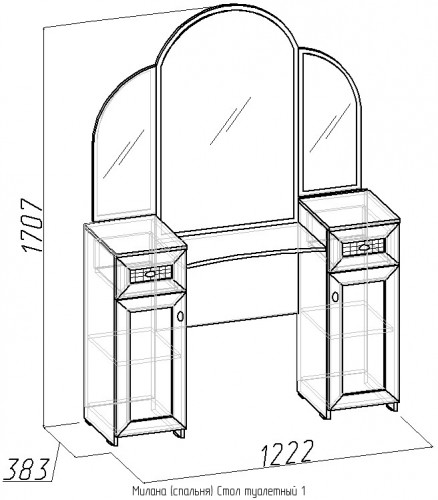

- Choose a suitable option for a toilet table. It can be with one cabinet or two. In one bedside table, you can mount drawers, and in the second make shelves and a facade door. An important detail is the capacity of the toilet table. There are many options and drawings for the toilet table, the photo of which are posted on the Internet.

- Start working with the drawing - scheme. Determine the place where the toilet table and approximate dimensions will stand. Plan the design of the table, better starting from the size of the countertop. The countertop, you can purchase the finished in the store or make it yourself. Facades for doors and drawers can also be bought or cut out of chipboard.

- If you decide that the mirror will be fixed monolithic on the toilet table, then chip is used for the rear wall and it is made continuous, as it is shown in the drawing. In other versions, the mirror can be fixed separately on the wall.

Marking holes for confirmation

- A carpentry corner is applied to the flat side of the part. With a pencil or marker, a mark is placed in the place of drilling. An awl rinses the point under the drill. Next, a thin perpendicular line is drawn to the edge and strictly vertical along the end. The workpiece is turned over on the back and using the corner, a serif is made on the opposite side.

- On the end side, marking is easier. Pencil surrounds perpendicular to the edge are made. The center of the plane is measured and core is carried out.

- Senses for confirmation are made by a drill with a diameter of 5 mm. The chamfer (zenkovka) is removed by a 8 mm drill with a diameter of 8 mm, to a depth of not more than 2 mm. In the end side of the part, the hole is drilled to a depth of not more than 40 mm.

Pattern and assembly of the toilet table

- You can cut out the parts for assembly yourself with an electrician, but high accuracy, cleanliness of the cut and compliance with curly cutting is necessary. Self -carved end surfaces, subsequently decorated with “P” - with a figurative cante or flat tape with an end.

- The texture and thickness of the chipboard, you will pick up yourself. The standard thickness is 1.6 cm, it is consistent with the technical requirements for the manufacture of furniture, the toilet table is no exception. Prepared details for assembling the toilet table with your own hands are processed on the end sides of sandpaper. Inevitable in such situations, chips of laminated coating are subsequently decorated with an end edge.

- The main frame of the toilet table is folded in mating surfaces, centered on the holes and is made with confirmation. The hexagon key No. 6, the confirmation are delayed until the gaps disappear between the mating surfaces and to the stable state of the design of the toilet table.

- For a more durable fastening, in the area of \u200b\u200bthe interfacing of the sidewalls and the horizontal plane, the tsar and several metal corners are installed.

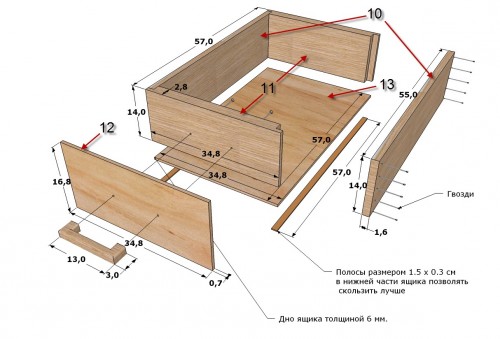

Assembly of drawers and hanging facade doors

- The side planks of the boxes are inhabited in the plane for confirmation, and the front and back walls in the end. The bottom of the plywood or fiberboard is nailed to the lower part with small cloves and fixed with self -tapping screws with a step of 5 - 7 cm.

- The boxes of roller guides are screwed to the side sides with screws. A similar procedure is carried out on the inside of the side walls of the cabinet. The guides are divided into right -sided and left -handed. It is important not to confuse them.

- To install overhead loops, in the manufacture of a dressing table with your own hands, you will need a special force drill with a diameter of 35 mm. The hole under the loop is drilled to a depth of 12.5 mm. It is important not to drill the surface through. False loops are inserted into the cups and mounted with screws.

- On the facades of the door of the cabinets and drawers, holes for handles are drilled. To do this, you need a drill of 5 or 5.5 mm. Furniture handles are installed and clamped by a screwdriver.

- The mirror is attached using special plastic mounts or on glue. A special double -sided tape for mirrors has now appeared in construction stores. Before the final installation, make a thorough marking of the mirror on the mounting plane of the toilet table.