Warm floor today is increasingly used as the main heating of the room. But not always the material of the floor covering allows you to arrange such heating. Among them, the laminate is not the last place. The fact is that this material is very impractical in rooms with high temperature and humidity. Indeed, depending on changes in temperature and humidity, it can change geometric parameters. However, there are some exceptions. Let's figure out how to make a warm floor under the laminate.

Content

How to choose a laminate for a warm floor?

Many people, in the houses of which the floor covered with a laminate, know that no insulation can make it warmer to the touch. After all, there is no wood in the surface of this material. In order to resist abrasion, this building material is covered with a layer of strong resin. Because of this, the surface remains cool even in the hottest weather. If you put a warm floor under the laminate, then the room will become much warmer. But it is worth saying right away that not any type of laminate and not every warm floor system is suitable for such a purpose.

The laminate itself in its composition still contains wood. Therefore, he has some properties of this material. In particular, he absorbs moisture and for this reason swells. In addition, in some cases he can deform and refer. For example, with a sharp increase in temperature.

Of course, these properties are not as strong as that of pure wood, but when choosing a laminate, you still need to pay attention to some important indicators. In particular, on the packaging of goods, as a rule, there is a special icon, which indicates the compatibility of the coating with a warm floor. It is important that the thickness of the material is at least 9 mm. If the laminate is thinner, it can be deformed due to temperature differences.

Before choosing a laminate, you need to figure out what it consists of. It is made by pressing the components (for example, wood dust). These components are fastened with each other with the help of various tight resins in which there is formaldehyde gas. And he, in turn, under certain conditions becomes harmful to our health. This gas is released when the laminate is heated above +25 degrees. Therefore, this material is usually used in those rooms, the temperature of which remains within 0 ...+25 degrees.

When a choice is made in favor of a particular type of laminate, you should learn more about the characteristics of the material that are usually indicated on the packaging. The coating must have thermal conductivity. For a warm floor, the coefficient is considered a suitable value of the coefficient 0.05 - 10 (measured in M2 x to/W). It is recommended to ask sellers a certificate for the laminate they sold. It must indicate the conditions in which this material can be used. In addition, its characteristics should be clearly spelled out there.

This is perhaps all the basic requirements for the laminate. Next, we consider how to choose a warm floor system.

The choice of a suitable warm floor system

Today, three options for floor heating systems are used:

- electric,

- water,

- film (infrared).

It is worth saying right away that not all of them suit the laminate. To find out, we will consider a little more than each of these options.

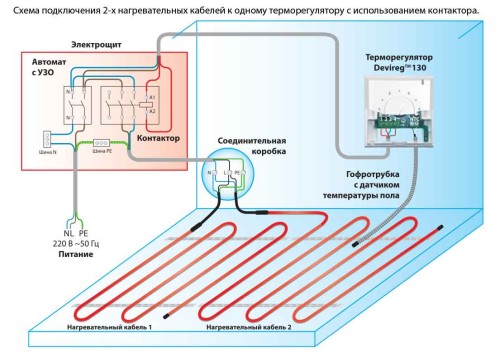

Electric warm floor under the laminate. Most often, this option is used for heating the premises, but it is poorly suitable for laminate and, in general, for most flooring. This is due to the fact that he has low thermal conductivity. The cable, which serves as the basis for heating, is poured with a screed on which the flooring material is then laid. First, with the help of the cable, the screed is heated, after which it should transfer the heat to the installed flooring. When carrying out the laminate work under it, a substrate is usually laid under it with low heat transfer. Therefore, it reduces even more weak burial. Therefore, so that the laminate can heat up to an acceptable temperature, you will have to wait enough for a long time. During this time, a large amount of electricity will spend. By the way, it is the most effective electrical system to use to convey heat to the coating of tiles and porcelain tiles. This is due to the fact that these materials, unlike laminate, have high thermal conductivity.

Now let's figure out what a water warm floor is. So, this is a system of pipes of a small section, which is directly connected to the central heating. This design of the warm floor is usually laid under the laminate, but not in apartment buildings. This can only be done in private buildings. The disadvantages should also include the costs of installing and maintaining a water floor for a laminate. If there is a malfunction, then its repair to the owners of the premises is poured into a rather large amount. Even with a small leak, you will have to change the entire system of pipes and, most likely, the laminate itself, which, due to such a malfunction, can become unusable. In addition, due to connecting the warm floor system, strong temperature changes are possible to the central heating, which is harmful to the laminate.

As for the film infrared floor, this is a system whose work is based on the effect of infrared radiation. The basic material of such a coating is a thin film penetrated by special strips conducting current. This warm floor system is considered the most suitable for styling for such a material as a laminate. This is facilitated by some important features. In particular, you can install this type of coating, even if screeds and glue are not available. He shows himself well with heating coatings with low thermal conductivity. In such variants of the warm floor, you can regulate the intensity of heating. Thanks to this, you can choose the most comfortable temperature regime for both the residents of the room and for the flooring (so that it does not spoil and does not deform).

From the foregoing, one can understand that the most suitable insulation for the floor with a laminate is the infrared film system. By the way, today there is even a laminate in which a heating film is already built. But so far such material has a very high price.

How to lay a warm floor under a laminate

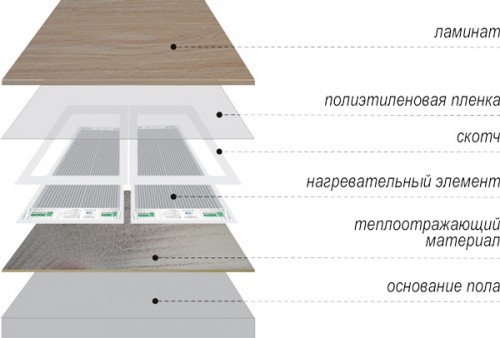

The system of filler warm floor under the laminate is easy to install. In this case, the knowledge of electricians will be very useful. Due to the fact that the film is very thin, such a floor, unlike other heating systems, does not reduce the height of the room. The laminate is laid directly on it. As a substrate during installation, you can take a special material with a soft base. He must have a coating made of metallized film.

The phased procedure for the performance of work:

- When installing an infrared warm floor, you do not need to remove the old coating under the laminate. But sometimes it is still worth doing. For example, when it can no longer fulfill its functions. In the event that the coating is still in good condition, then to prepare it will be enough to clean from garbage and dirt.

- The surface may not be perfectly flat, as required by installation conditions. Therefore, it is worth checking the presence of differences and hollows using the construction level. For the infrared floor, bends equal to the thickness of the film are acceptable. If the differences are larger, then they should be leveled. Then the floor needs to be dried. Now you can start installing the warm floor system itself.

- It makes no sense to warm the floor area on which furniture and appliances will stand. But if you plan to change the layout of the room in the future, it is better to insulate the entire surface of the coating. It must be remembered that the power of the warm floor system depends directly on the area of \u200b\u200bthe room. The more it is, the less power consumes.

- How to put a warm floor under a laminate? The first stage should be laid waterproofing, which is needed to protect heating from moisture. Next, a layer of thermal insulation is installed, which prevents heat loss from radiation directed down. This layer of material allows you to reduce energy consumption and increase the efficiency of the system.

- To make thermal insulation, it is allowed to use almost any materials intended for these purposes. Which one you did not choose, it will need to be thoroughly straightened and installed by the side with a metal coating up. The joints are recommended to glue with tape. It is believed that for the laminate as thermal insulation it is best to use foamed material, the thickness of which is about 4 mm. It doesn’t matter if he will have reflective properties. The most important thing here is only the thickness of this layer.

- As a rule, the reflective coating is made from Lavsan. With an infrared warm floor under the laminate, it is not recommended to use the heat -insulating material made of foil. In order to reduce heat loss, the joints of the substrates must be sealed with special tape with metal spraying.

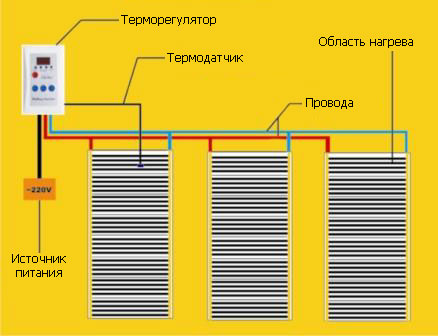

- For a warm floor, temperature adjustment is needed. This is usually done using a thermostat. The thermostat allows you to perform the following - set the basic temperature level, set the heating period of the frequency of the heating, and it is also designed to automate the inclusion and off of the heating.

- Before installing an infrared warm floor, you need to choose the place where you will place the thermostat. It is best to place it at a height of 200 mm from the floor level. How the sheets of thermal puffs will be attached to the correct placement of the correct placement and the wires are laid. After that, it is necessary to draw up a diagram of installation of a warm floor under the laminate.

- The installation of the thermal member should be made directly on thermal insulation, and according to the previously intended scheme. There is no need to insulate the entire floor of the room. Therefore, the film warm floor under the laminate is usually mounted only on areas of the room that will be useful.

- When there is the main source of heat and additional heating is needed, the polyester film is laid on half the area of \u200b\u200bthe entire floor. Moreover, its power should be from 90 to 150 W/m2. In this case, the warm floor in the finished form should be quite comfortable for the tenants of the room. If the floor is created as the main heating, then the film is laid on 75-85% of its area. In this case, its power should already be 150 W/m2.

- There are some important rules for installing a thermal puff. In particular, at least 200 mm should be from the wall. In addition, do not place it near furniture. If there are strong heating devices in the room (for example, a fireplace), then there should be a distance of at least 1.1 m. In order to correctly place a thermal grinder, it can be cut using scissors according to the marked marks in advance in advance. We must not forget that the strip in length should not exceed 7.5 m.

- When installing the film, you need to ensure that there are no impositions of its individual parts on each other. The thermal male can have one or two working sides. In the first case (in the presence of a one -sided film), the system is laid down the reinforced side. Bilateral film can be mounted with any side. To make the wires smaller, it is recommended to install it in the place where you will place a temperature control. The material must be laid so that the contacts with copper sides look down, after which clamps join the edge of the copper cable, and the remaining wires are already connected to them.

- Open areas of copper should be closed with insulation. For these purposes, bitumen isolation is suitable, which is sold in the form of a film. The piece cut off from it should be slightly larger in size than the working surface.

- With the help of insulation, copper areas are glued on both sides. To place the isolated area, holes are made by pressing in the film. Then they are sealed with tape. At the place of fastening of the wire, insulation is not yet necessary. Pre -prepare metal clamps. For their fastening, pliers are used.

As you can see, install warm floors under the laminate with your own hands can do it with it.

Installation of the skirting board

When the installation of the laminate will come to an end, a plinth is mounted on it. Only after this work can be considered complete. In order to install a plastic skirting board, a knife -haired carriage and drill will be needed from the tools, and self -tapping screws and dowels will be made of fasteners. Plinks of plastic of the desired shade are also purchased for skirting boards. In the doorway, skirting rails are closed with plugs. Reiki are cut in accordance with the size. In the walls, holes designed for dowels should be made.

If the plans to install a wooden skirting board, then the carpentry knock will come in handy, which is a device that helps to cut wooden details (in our case, the baseboard) is at an angle of 45 degrees. After installation in the knock, the material is cut using a hacksaw. As a result, two adjacent skirting boards are connected by a beautiful and correct joint.

General styling tips

- Even before the start of work, it is recommended to prepare a diagram, or rather, the plan according to which styling will be done. When compiling it, it is better to consult with professionals who can indicate important points.

- In small rooms with low ceilings, it is advisable to use thin layers of a warm floor. The choice of such materials is quite wide.

- You should choose the right type of warm floor under the laminate, given the quality characteristics of the material.

- In order to only go up, it is recommended to install an additional layer of thermal insulation under the design of the warm floor.

- If the floor is located on the border with a wet cellar or close to the soil, then when installing the heating system, it is best to install additional waterproofing.

- When laying a warm floor under the laminate, the temperature sensor is best placed in the middle of the structure. Thanks to this, less wires will be needed in the installation process. In addition, this sensor must be located in the cool place. It should also be wrapped in a corrugated sleeve.

- The installation of a warm floor system should be made strictly in accordance with the existing instruction.

- If the building has different rooms in the climate, then you can not use the same system of warm floors in them. So, for example, you should not lay one floor for a room and loggia. If you insulate these rooms, then for each of them there should be a separate system.

- If the room has high humidity, then it is not recommended to install a thermal gun in it.

- To fasten the thermal deer itself, you can not use screws and nails.

- If massive furniture is planned to be installed on such a floor, then it is necessary to make air pockets in advance.

- In the thermal dealer you can not make holes.

- In addition, such a floor should not be installed at low temperature.

- During installation, a film of 50 cm long cannot be bent at right angles.

- Take care that the grounding of the wires is present.