Frame houses first appeared in the United States, but over the past few years, a similar practice of construction has gained popularity in domestic expanses. Despite a number of advantages of such buildings, inexpensive and ergonomic houses have one significant drawback - a low heat insulation indicator. It is for this reason that the insulation of the walls of the frame house becomes a priority task when erecting a building.

Content

The choice of optimal insulation

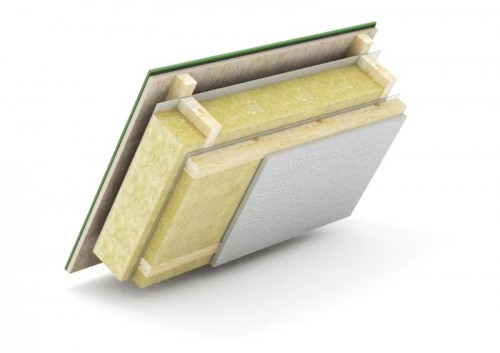

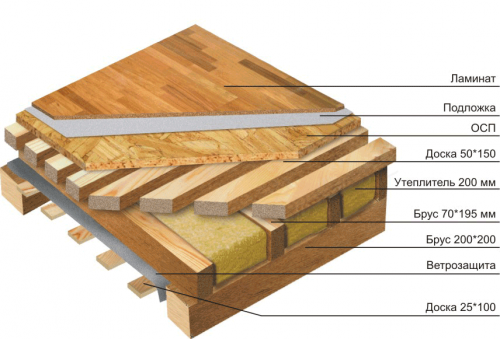

The technology of insulation of the walls of the frame house will be from the type of insulating material selected for wall cladding. Since normal humidity in the room and maintenance of heat inside are important criteria for comfortable living, the choice of material should be approached with responsibility and scrupulousness.

In general, all thermal insulation materials can be divided into two groups:

- organic;

- synthetic.

The first category falls raw materials of natural origin, for example, tyrs, peat, chips, etc. Such materials are environmentally friendly and do not harm human health during operation, but they are impractical: a high degree of combustibility, moisture and low thermal insulation is not the best option for insulation of modern construction.

The second group includes more technological heater, which provide reliable thermal insulation of the room. These include:

- balzate mineral wool;

- ecowata;

- fiberglass cotton wool;

- foam and foam;

- stone cotton wool.

Consider the features of the operation of each material in more detail:

- Basalt Minvata - one of the highest quality absorbing materials that has significant advantages: resistance to biological corrosion, low combustibility, good sound insulation, resistance to moisture and sunlight.

- Glass wool - material with high vapor permeability. Also, this insulation is easy to install and does not break up over time. However, with the thermal insulation of the walls with glassy, \u200b\u200bit is necessary to additionally attach a special film, which helps to keep heat inside the house.

- Ecowata - A relatively new seal, which is a cellulose fiber. It is of natural origin, does not require installation of films and has good heat -insulating properties. The insulation of the walls of the frame house is relevant for those who seek to make the house environmentally friendly.

- Foam and foam - The most popular materials for insulation of the room. The advantage of such raw materials consists in high moisture resistance, due to which it is not necessary to lay a steam protection membrane. As well as insulation of the walls of the frame house by foam is much cheaper than analogues, while the quality of the achieved does not change.

- Stone cotton wool - A new finishing material that is rapidly gaining popularity. This type of insulation has good water -repellent properties and flexibility. It differs in durability during operation and easy to install.

Insulation of the walls of the frame house outside

The loss of thermal insulation properties in frame houses occurs through the walls of the structure. This indicator often exceeds 40% of the total heat loss of the building. Therefore, the process of wall cladding can be carried out both by the external method and choose the interior decoration of surfaces. The most appropriate and practical solution will be the outer thermal insulation of the house, since it is much easier to lay material from the street.

Since polystyrene is the most popular and affordable insulation, we consider the process of thermal insulation cladding of walls on the example of this material.

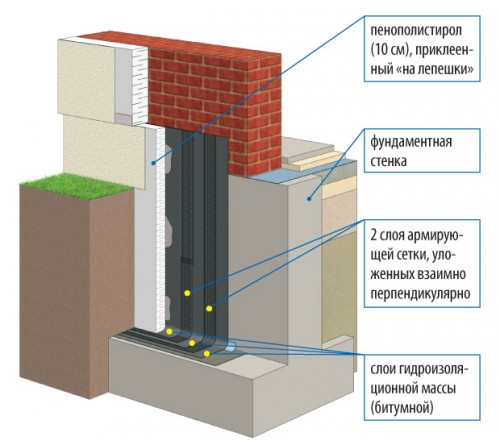

Step 1: Waterproofing surface

- Prepare waterproofing material. For these purposes, Permamine is best suited, the water absorption of which is 20% per day.

- Cover the roll in accordance with the size of the frame sections.

- Using a construction stapler, fix the peramin to the sheathing and designs. Strengthen at the joints at the intervals of 10-13 cm.

Important! Fragments of the layer must be laid, making a lining 10 cm.

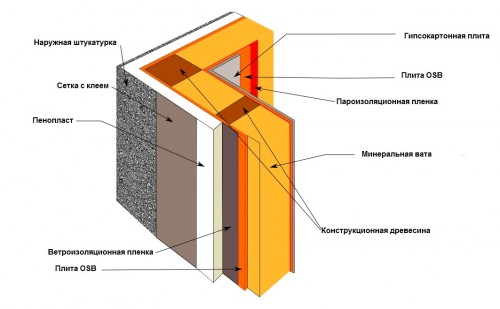

Step 2: laying a vapor barrier membrane

This stage in the insulation of the walls of the frame building is necessary even if you put the highest quality insulating materials that are not afraid of moisture. The reason is the peculiarity that in addition to the insulation in the wall pie of the house, there are other elements. They also need protection from steam penetrating inside the wall.

Consider the step -by -step guide for laying a vapor barrier membrane:

- This material is fixed to the construction of the frame through a construction stapler so that the film is close to the seal.

- As in the case of waterproofing, the joints of the membrane should be overlapped, leaving the lining of at least 10 cm.

- For the best result, all the junction must be strengthened with aluminum tape.

Important! Sometimes builders resort to such a vapor barrier method as a simple winding of insulation sheets with a membrane. However, this technique will not be able to protect all elements of the frame.

Step 3: Supply laying

- Prepare foam plates by cutting them into the required dimensions, depending on the dimensions of the frame sections. For this, an electrician or a hacksaw with small teeth is used.

- Lay the insulation between the racks so that the sheets lie evenly, and in the places of adjacent to the wooden bars there were 2-3 cm for ventilation.

- Each foam plate is attached to the base of the walls by means of special compositions: two -component - adhesive and leveling, or one universal.

- For strength, glued blocks must be fixed with mounts - umbrellas or fungi.

Step 4: Wall cladding

After the process of insulation of the walls of the frame building is completed, it is necessary to make surfaces. For this, plasterboard sheets or OSB plates are suitable.

- drywall is recommended to be applied to perfectly even walls;

- The OSB can be mounted on any surface, since the rigidity of the material will allow you to hide and leve flaws on the wall.

On top of these facing materials, you can perform a decorative surface decoration.

Wall insulation from the inside of the frame house

This technique of thermal insulation is carried out according to a similar principle with insulation of the outer surface of the house. However, minor differences in techniques are still present. Consider them more detailed:

- The surface of the wall must be prepared: cleaned and aligned flaws.

- Then the walls are carefully treated with a primer.

- Then you can start laying foam sheets. The mounting methodology is similar to the previous one - first the slabs are glued, then fixed with fixing materials.

- Plasterboard sheets are laid on top, which are also fixed using mounting glue, and for reliability they are fixed with dowels-zontics.

- After that, finishing and decorative wall cladding are made.

Important! You should know that wall insulation from the inside is less effective than external insulation, while thermal insulation material significantly reduces the size of the room. Such a technique is extremely rare, if it is impossible to carry out external work.

The instruction regarding the process of insulation of the walls of the frame building is presented on video fragments: