Metal tape is a relatively new material, but firmly gained authority among the consumer. Due to its numerous properties, from aesthetic appearance to reliability and quality, more and more builders and their customers choose the roof covering precisely with a metal tile.

Content

It is quite difficult to cover the roof with a metal tile with your own hands if you do not have construction experience. However, experts argue that when studying detailed instructions and the availability of sensible assistants, especially if the roof that needs to be covered in the usual shape, then nothing is impossible.

The main advantages of metal tiles

Along with the widest spectrum of roofing materials, the metal tile today is in great demand. This is due to the whole spectrum of its advantages:

- excellent resistance to different temperatures, as well as its differences;

- durability of use - bright colors of metal tiles actually do not burn out in the sun over the years, and your house will be as new and after many years;

- strength is the undeniable quality of metal tiles. Production will improve for 30 years of its existence in the market, today it is a complex process of covering the profiled sheet of galvanized steel specially designed polymers and varnish;

- the cost of coating the roof with a metal tile is quite loyal, which also speaks in favor of choosing this particular material;

- roofs covered precisely with metal tiles look aesthetically pleasing, rich and beautiful.

Delivery and storage of material

Having selected profiled sheets in the store, several questions may arise with their delivery to the construction site. Here are a few important tips that need to be taken into account:

- direct loading and unloading of the material should be carried out exclusively in a mechanized way. Only in this case, the manufacturer retains its guarantee obligations;

- if you acquire a lot of material and do not plan to start its installation for a long time, then the sheets must be unpacked and lay on each other, be sure to separate with wooden strips

- make sure that the workers carry the sheets, holding them at the top along the sheet. The transfer of sheets should be carried out at the rate of 1 person per 1.5 linear meters of Mathel. In no case should the sheets bend the sheets bend.

Roofing technology

The technology of roof covering with a metal tile implies several rather difficult stages:

- installation of a roof pie;

- trimming and preparation of profiled sheets for installation;

- laying and fixing with metal tiles to the crate.

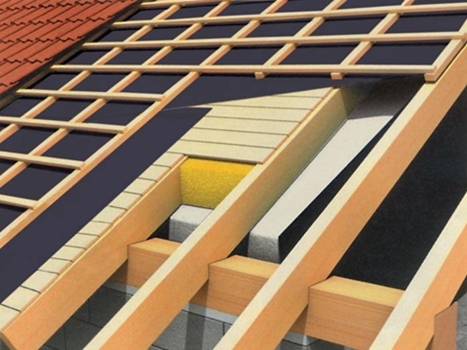

Installation of a roof pie

It is important to consider that the technology of roof covering with a metal tile, first of all, requires the preparation of the roof pie. A pie is called a structure of several layers, each of which has its own purpose. The design of the pie differs depending on whether the construction of a warm or cold roof is planned.

The cold roof is most often selected for non -residential premises and includes:

- layer of waterproofing film;

- counterparty;

- crate;

- initial crate;

- rafter.

A warm roof involves a more complex design of the roof pie, which is why the roof covering with a metal tile will slightly increase its price, but the monetary factor here plays a lesser role, since the roof over the head is done for many years. The roofing pie of the warm roof enters:

- one -way vapor barrier that will produce wet air, but not let in;

- the rafter system that will carry the main, bearing function for the roof. It includes both rafters and longitudinal runs;

- inside the rafter system, a layer of thermal insulation materials is poured;

- among thermal insulation, you must certainly leave a ventilation gap;

- the counterpart performs several functions at once: fixes the waterproofing and is a mount for the crate;

- the crate, on which a sheet of metal tiles is later attached. The material for the crate can be wooden bars treated with a special antiseptic, as well as a perforated profile made of galvanized steel. The crate is fixed with a certain step, which usually does not exceed 45 cm;

- metal tile.

Cutting and installation of sheets of metal tiles

Cutting sheets of metal tiles is the initial stage of its installation. Almost always, it has to be performed on the ground, after which already lifting it to the roof. In general, experts recommend resorting to cutting it as little as possible, but if such a need arises, you should always remember several rules:

- personal protective equipment in the form of glasses and gloves should always be with you, do not neglect them;

- cutting sheets of metal tiles involves the lack of use of any abrasive tools, this will damage the protective layer of coating. Use an electrician or a disk saw;

- the seats of the cuts should also be protected. To do this, be sure to purchase a special paint and cover it with an unprotected leaf layer.

Moving directly to the installation, first remember that the cut areas should be attached to whole - this will retain the durability of the coating.

Fixation of metal tile sheets

For fasteners of metal tiles, special screws are used, the size of which is 4.8x28 mm. Self -tapping screws should be covered with a special protective coating to the color of the metal tile itself. The average consumption of screws on the roof is correctly up to 10 pcs. 1 m 2.

- For more dense fixation, it is important to use goals to compile screws.

- Before fixing, a sheet of metal tiles must be drilled at the locations of the screws. It is not recommended to screw them independently, because this is how you can damage the protective layer with which the sheet is covered.

- An important point should be that the self -tapping screw is attached exclusively perpendicular to the crate, any slope is not allowed.

- When fixing the screws, calculate the force: it should not attach the metal tile to the crate too tightly, the roof should be a little pressed. But too weak fixation cannot be left.

- Additional fixation with self -tapping screws require a place where there are overlaps - this will increase the reliability of the roof.

- Starting the roof, first align the ends regarding the cornice, after which only you need to start fixing.

Depending on which shape is the lingering roof, there are several main technologies for the beginning of the roof covering with a metal tile:

- with a roof of a gable roof, you can start with the end, from the right or left - it does not matter;

- if the sheets began to be laid on the right, then the edge should be applied to the previous one, and if on the left, then under the previous sheet;

- if the roof is shallow, then the sheets of metal tiles must be laid down and go to the sides as installed.

Having completed the styling on the slopes of the roof, you need to proceed to the installation of the final elements. The roof hobble is decorated with a ridge bar, with self -tapping screws you need to fix all the skate elements of the metal tile. The butt strips are attached to all places where the leaves of the tile are adjacent to the vertical surface.

How much does it cost to cover the roof?

Of course, this issue remains the most popular, because proceeding to coating the roof with a metal tile, it is important to know full prices. They will depend on several factors:

- view of the roof: cold roof will be the cheapest option; Warm requires a complex design of the roof of the roof;

- who performs work: by doing all the work on their own, you can save on wages. But if you do not adhere to a certain technology, then you risk reducing the life of your roof many times. Starting the roof roof yourself, you need to carefully study all the instructions, the opinions of specialists and watch the training video on the topic “Coating the roof of a metal tile”;

- by hiring a team of builders, make sure of its competence, because if the work is done poorly, then in a few years you will have to start work again, which will double, or maybe the cost of the overlap will triple.