Glass tiles in the interior - stylish modern design solution. And the most pleasant thing to make the material can be handled using cheap and affordable glass waste. What is good such a tile and how to make it we will tell in this article.

Content

Pros and Cons Glass Tile

The benefits of glass tiles are quite a lot, let's look at them:

- A distinctive feature of the glass is the ability to reflect most of the light falling on it. Thanks to this, the glass tiles used in the interior makes the space around the lighter and spacious, and this is relevant for small rooms and rooms where little natural sunlight falls.

- It is good to use glass tiles and low ceilings. Such a design element visually will increase the height of the walls.

- The glass is not scary moisture and water, which means for bathrooms, toilets and kitchens such a solution is a huge plus.

- Wash the glass tile can be anything, not afraid of its destruction and damage.

- Material preserves its color for long years, practically without an ultraviolet.

- It is famous for a glass tile and its decorative qualities, because it is much more attractive and more beautiful than other types of finishes. The material looks stylish and often applied in design to create a luxury effect.

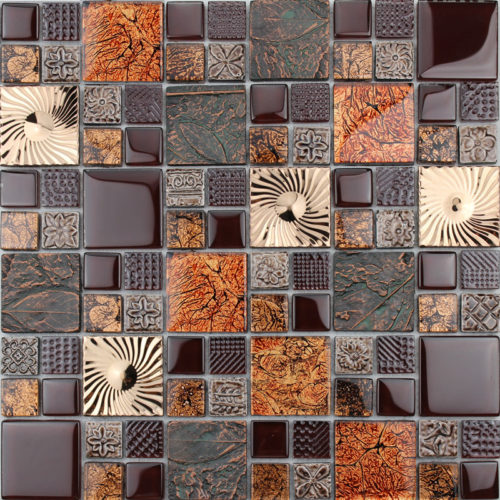

- He has a glass tile and a rich assortment of flowers, sizes, drawings, textures. Of all the variety of material species, you can create not only a monochrome surface, but also a mosaic or panel.

- Finished glass tile on sale is represented by a large amount of sizes.

The disadvantages of the material is a bit. The most weighty, perhaps, is the brittleness glass. The tile does not withstand significant mechanical impacts, although it transfers weak blows. You need to handle it carefully, and during the installation to make a durable and high-quality framework.

Where the glass tile is used

The scope of application of glass tiles is extremely wide. It can be found both in residential buildings and apartments and in public premises. Very often, it is used in rooms with "unfavorable" surrounding conditions: in kitchens, toilets, bathrooms, that is, where the humidity is increased and there are frequent temperature differences.

Glass tiles are a real rescue for close spaces. For example, to add the premises at least visually light and space, the tile can be laid on the diagonal, as well as arrange the ceiling. With this purpose, the material is used in narrow corridors, where there is not enough natural lighting.

The kitchen looks beautifully a decorative glass tile tape, the material is also used to create kitchen aprons or complete wall decorations or ceiling. Design with such a tile will be stylish, elegant, sophisticated. Very relevant material and for those kitchens, where there is a bar counter. The glass tile can be used as the main facing material, and you can make it a reflected interior addition, laying out a stylish panel or mosaic pattern.

How to make tiles of glass waste

Glass tile manufacturing technology is simple, therefore, at home, you can make a similar material. The so-called "cold" method of production says that no components will have to heat or melted. For the manufacture of tiles, glass waste will be useful, and therefore the finished product will be cost-effective. Briefly, the whole process can be divided into several stages:

- Initially, forms are prepared for the production of tiles of broken glass, directly glass itself and a binding component.

- Glass waste is crushed into small fragments, stirred with a binder.

- The dye is added to the mass and also mixes with the rest of the components.

- This mixture is poured into the forms where it finally freezes.

- Then the material can be divided into more convenient parts.

The manufactured glass tile made will be unique and unique, and in quality can compete with Italian counterparts. At the same time, it will cost you much cheaper, because the cost of it is relatively low, and you will not suffer any additional spending.

Consider which materials may be needed for the production of glass tiles:

- Glass waste is the main component of the material - can be obtained free of charge, for example, in glass workshops or in windows manufacturing companies. As a last resort, if the waste is not given to you for free, they will be sold for a symbolic price.

- As a binder component, it is convenient to use a polyester resin, the price of which is also very acceptable. For 1 kg of broken glass will take about 50 g of resin.

- Those who decide to produce tiles in large quantities, for example, for sale, will have to get the electric glass crusher. The device can be made both personally, and buy in a specialized store.

- To compose the material, you will need the corresponding dyes. They will help the stack of tiles at the mixing stage of the components, because its entire thickness will have a certain tone that does not burn out in the sun.

For the production of tiles for sale, it will be advisable to find suppliers of raw materials. Working with polyester resin also has its subtleties. It is known that the material freezes pretty quickly - for an hour, and during this time you need to have time to mix the components and pour them into forms.

In the process of work in the thickness of the material, small air bubbles are often formed. If you want, they were not in the tile, and the structure was homogeneous, acquire a vacuum installation. Forms with a mixture are placed in such an installation for 2 hours, after which the quality material with a homogeneous dense structure is ready.

By approximate calculations, the equipment for the production of tile costs more than 3000 rubles, for reusable forms will also have to pay from 200 rubles per 1 m². But the process of manufacturing the tile is quite fast, as well as the payback of such business.

How to make a tile of transparent glass do it yourself

Cut the tile of the desired size from the sheet glass and decorate it at its discretion you can own it, and they will need such devices for this:

- sample;

- diamond glass cutter;

- awl;

- foam

- small-grained sandpaper;

- glass sheet;

- oil paints;

- nitroemali;

- local sand.

Cutting and decorating tile occurs in this way:

- The table on which glass will be cut must be even and stable. It is covered with matter to avoid sliding material. For cutting material, the template of the desired size is prepared.

- From the left end on the table, the limiter is mounted, which will not allow the glass to be shifted during operation. The thickness of the restrictive bar must be greater than the overall thickness of the glass and the template imposed on it.

- Applying a template to the glass and resting them into the limiter, the material is divided by a diamond glass cutter into fragments.

- The fine-grained sandpaper is attached to a wooden bar and grind the edges of the tiles carefully. Then the products are washed with water and dried.

- Now the tiles can be painted. Note that the paint should be rack, quickly dry, hold well. To decorate the glass, nitroemali or compositions are perfectly suitable for painting road signs.

- Choosing a color, it is necessary to prepare the right amount of paint - it should be enough for the entire batch. The second time to pick up an identical shade will be impossible, so try to immediately paint the entire tile that will be used.

- Pour the paint to the liter can, and the remnants, if you eat, are tightly close and hide away from the sources of fire and heating appliances. Paints from liter cans are enough for 30-45 tiles in size 20x20 cm.

- To compose a tile in a background hue, break a small amount of paint into a small container, dip a piece of foam rubber and stuff the composition on the glass with a smooth layer without cleansing. After drying, repeat the procedure and apply another thin layer of the dye.

- Painting in this way 10-15 parts, you can depict any ornament. To do this, transfer the drawing to the tile of a gouache, let it dry, and then the contour scratch the image with a sharp selection or needle fixed in the collet pencil. The paint needs to be scratched carefully, while the layer should not be stuck or crack it. He will be incurred if the paint did not dry, but to crack if it dryed. The composition may dry in 2-3 days, so work should be done before.

- Processed tiles are put in water for 20 minutes. Then, without wiping the item, from the scratched circuit, the same seer or needle cleaned the paint.

- The resulting pattern is clogged with another shade. The tile is dried and covered with a layer of oil paint.

- Then fresh paint sprinkle with sand, and the tiles arrange in a vertical position. Excess sand after drying is crushed itself, and the remaining will create a rough surface, which will allow securing tiles on the wall. Tile dries over 2-3 days, then it is ready for installation.

In this way, you can make tiles of any sizes and shapes. If, for example, the tile will perform the role of a decorative ribbon, then it is necessary to cut it with oblong narrow fragments.