Everyone knows about such products necessary in the farm as house signs . Usually they are mounted on the facades of fences or buildings on the street side and contain information about the place of residence of the owner, as well as the name of the organization or institution.

Content

Similar address signs can be purchased both in specialized offices and construction stores of a common profile, however, if desired, they can be made personally. A wide range of materials will make it possible to build not only a functional, but also a beautiful home plate.

Varieties of address plates

Modern production technologies allow you to make products in various forms, colors and sizes of the tablet. The number of the house, as well as the stylistics of the design, completely depends on the individual requirements of the customer. Today, products from materials such as::

- stainless steel;

- PVC;

- bronze;

- tree;

- brass;

- copper;

- oracal film;

- acrylic;

- organic glass.

Also, address signs may vary in form. The assortment range of products allows you to purchase rounded, polygonal, square, rectangular or oval signs.

Methods for the manufacture of targeted signs

The availability of materials, along with the desire to build original targets to the house, leads to the fact that the methodology of the signal manufacture of the sign is becoming increasingly popular. There are several options for the implementation of the plan. At the same time, there is the possibility of a full -fledged minting “from scratch”, or buying a finished base followed by decoration of a plate.

Production technology and manufacturing technology may vary depending on the selected materials, tools and wishes of the master. Consider some methods of your own manufacture of house signs.

Target

The inscription on the plastic surface is applied using special colorful materials or the engraving method. Such methods will require work on profile equipment, and therefore are not suitable for independent development. The only possible option for home production is a signs is an Oracal film. You can buy a ready -made set of workpieces and get to work:

- The vinyl film, previously chopped on a plotter, must be glued to the base using a special mounting shell. A wooden, metal or plastic base can act as a fixing workpiece.

- Then the film should be thoroughly led.

- After removing all air bubbles, carefully remove the mounting layer.

- At the end of the work, delete unnecessary fragments around the letter and digital designations.

Such a product can last from 2 to 12 years, depending on the quality of materials and operating conditions.

Target

Such a technique is suitable only for craftsmen who own the art of woodcarving. In this case, the process of manufacturing an targeted plate is reduced to the minimum actions:

- Initially, it is necessary to choose a workpiece, determining the appropriate size and texture of the material.

- Then the base is sanded.

- Following this, the name of the street and numbers are cut.

- The outer layer is painted in colors conceived by the master. In order for the information to be as readable as possible, it is better to highlight the letters and house number. To do this, apply contrasting tones - painted on light wood with dark paint and vice versa.

- To extend the service life of the product and protect against negative atmospheric exposure, you should cover the sign with transparent varnish in several layers.

As an alternative version of execution, you can apply information with a paint, working with a brush on a flat surface, without cutting the designations. After drying, just cover the plate with transparent varnish.

Home metal plate

Such a technique is more complicated and requires special skills. More recently, most targeting designations were made of galvanized plate, but today you can use any metal raw materials available in stock.

The name of the street and house number can be engraved in any convenient technique, paint or make an forged target sign. However, for such a performance, special equipment and experience will be needed, therefore it is recommended to entrust the manufacture of specialists. Let us consider in more detail the simplest methodology of your hand -made metal plate.

DIY targeting

By putting a little imagination and perseverance in practice, you can build an original and durable product. Even a novice master will be able to make a tablet to the house, since for the process of building a simple product you will need minimal skills of owning a construction tool.

Required materials and tools

The following tools and materials will be required to work:

- metal sheet;

- paper adhesive tape;

- cardboard sheet according to the size of the plate;

- diamond disk;

- file;

- moisture -resistant paint;

- set of hard brushes;

- oil paint;

- permanent marker;

- building gloves;

- protective glasses;

- roulette.

A step -by -step process of work

Let us consider in more detail the step -in -law guide for the manufacture of an targeted sign from metal:

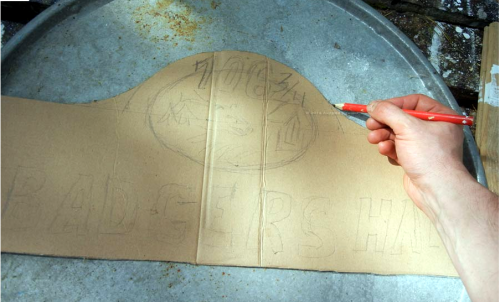

- Initially, it is necessary to determine the shape and stylistic image of the future plate. In this example, an address sign in a typical English style is taken for a sample.

- Then it is necessary to measure the main proportions and the style of the image taken from the photograph on the network.

- Since the cover from the barrel is taken behind the wooden base, a template should be cut out of cardboard, which will be slightly smaller than the circumference of the fragment.

- The outlines of the signs will be made in the style of “Bridge Style”, and therefore the bridge circuit must be drawn on a plate of suitable diameter.

- Following this, the template is transferred to the workpiece.

- Cut the plate along the contour using a grinder for this. It is advisable to put a diamond disk as a nozzle. For safety during work, it is worthwearing goggles and building gloves.

- Using the file, it is necessary to process the edges of the workpiece from irregularities and burrs.

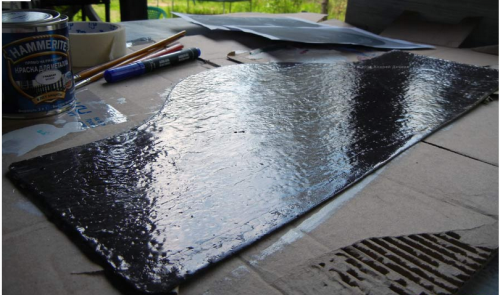

- Then cover the canvas of the future plate with a moisture -resistant paint in one layer. Let it dry for 24 hours.

- After that, it is necessary to apply a layer of any oil paint, deliberately making coarse strokes.

- Without letting the contents dry, cover from above with another layer of moisture -resistant paint. At the same time, make it thick to get the effect of an aged surface.

11. Using a hard brush, several smears should be applied with a light tone to create the effect of painting “on the lumen”.

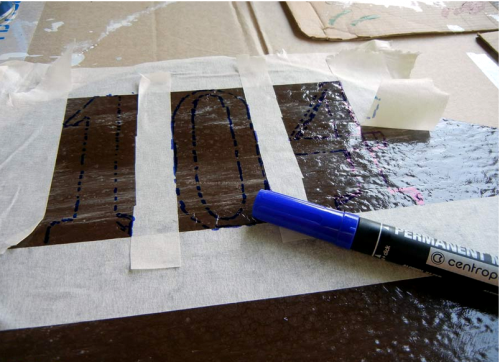

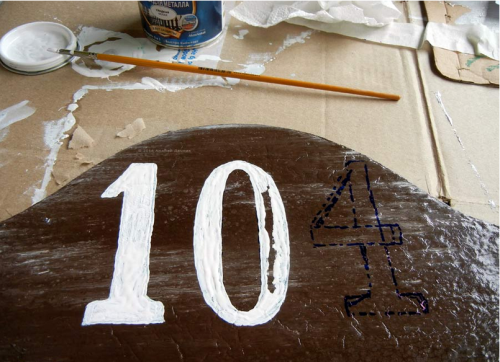

12. Thoroughly dry the surface and proceed to applying the house of the house. Initially, you need to make a template using paper tape.

13. Using a marker, enter the necessary numbers into the perimeter.

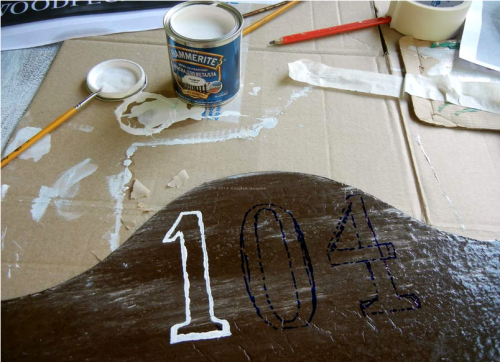

14. Circle the number with white paint. In order to make the circuit as even as possible, it is recommended to conduct a brush from the inside of the digital designation perpendicular to the lines.

15. After the circuit is applied, it is necessary to fill the space inside with the paint of the same color. In order to get the effect of engraving, you should put strokes at an angle, applying a fairly thick layer.

16. When the paint dries out, you can proceed to applying the name of the street at home. To get an even inscription, make a letter marking on the tape.

17. Designate letters based on a permanent marker.

18. Gently fit the letters with moisture -proof paint.

19. The plate is completely ready.

A video lesson in the manufacture of an targeted plate can be seen on a fragment: