Foam concrete is one of the latest developments in the field of construction. This material has many undeniable advantages and is very popular. Its cellular fractional structure is characterized by low thermal conductivity, which allows you to not spend money on additional insulation. Small weight and dimensions exceeding the size of a brick or sawn stone (the standard foam block - 600x300x200) can significantly save sand and cement during construction.

Content

Due to its unique porous structure, foam blocks have good sound insulation. The same properties create the effect of a “breathing” wall, which protects the extension from condensation that provokes the formation of mold or fungus. Environmentally friendly natural components are used to produce blocks from foam concrete.

Planning and drawings of an extension from foam concrete to the house

First of all, decide on the place of the extension, its size and height. It is important that the roof of the structure is slightly lower than the roof of the house.

- Provide and plan communications routes. This must be done at the initial stage of planning, otherwise you will face the problem of laying them after the construction of the walls.

- It is also required to provide for the possibility of a deformation suture in the places where the extension and main structure is spent.

- The doorway in the extension can be equipped in the place where the window is located on the outer wall of the house, or you can cut it out in the load -bearing wall. In this case, consider the external loads.

Arrangement of the base for the construction

It’s easier to build an extension to the house from foam blocks than from traditional materials. The foundation for an extension from foam blocks is made by a tape pouring method from concrete or from the elements of the future structure themselves.

- The depth of the base depends on the height and mass of the extension. For a small structure, it is enough to dig around the perimeter with a trench with a depth of 50 cm and a width of up to half a meter. At the time of laying the foundation from foam blocks, it is important to pay attention to the insulation and waterproofing of the underground part of the structure. The foundation is affected by groundwater and temperature differences.

- Moisture absorbed into the material in winter can freeze and contribute to the destruction of the base, and the condition of the walls depends on its strength. At the time of the start of construction, on the zero cycle, work on insulation and waterproofing begins. For insulation, polystyrene foam, mineral wool, foam and other materials are used.

- The laying of heat -insulating plates is carried out directly at the time of waterproofing. A dried foundation is coated with water -repellent mastic. Heat insulation slabs covered with hot, about +70 ° C, bitumen are attached to it. There is no need to fix them additionally. When filling the trench, the earth will press the insulation to the base. Elements of thermal insulation material should protrude over the ground by about 50 cm.

- There is another type of foundation insulation - polyurethane foam. This is a new and more expensive tool, but its use decides the issue of maintaining temperature and the implementation of waterproofing at the same time. Through a special machine, polyurethane is sprayed with a layer of up to 5 cm to the surface of the foundation. The coating of such a thickness corresponds to 12 cm of ordinary polystyrene foam.

These materials successfully cope with the task of insulation and waterproofing of the house and prevent the occurrence of cold bridges, which, in turn, protects the living room from mold and fungus on the internal walls.

Bill of walls for an extension from foam blocks

According to the frozen and surviving perimeter of the base, you can lay roofing material or rubles. Such a layer, laid along the level of the “dew”, prevents the penetration of moisture above the floor level.

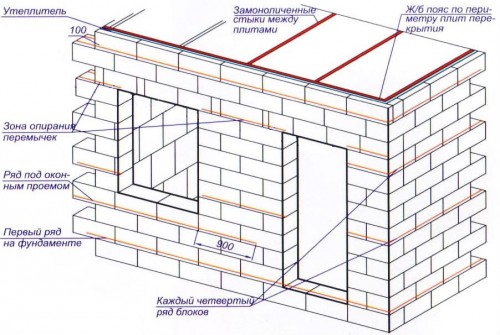

- When laying the first row of a wall of foam blocks, an ordinary cement mortar is used. Construction, as usual, should start from the corner. 3-4 horizontal rows of foam concrete blocks are laid out and it is time to grasp them. This is from an hour to three or four, depending on the cement glue composition used.

- In the places of attachment, the extensions to the wall of the house are driven by connecting embedded. They use trimming a metal rod or reinforcement with a diameter of 8 - 10 mm and a length of about 30 cm. The rod is driven into the wall to half the length, and the protruding part should accurately lie into the seam between the foam concrete blocks.

- When erecting walls, constantly check the horizontal rows and vertical structure with a level and plumb line. The last row of the wall is made taking into account the laying of rafter beams for the roof. It is possible to make a gable or single -slop, as well as a cascading roof of the extension.

External and interior wall decoration from foam concrete

- Pentone itself has all the necessary technological properties for the construction of any structure. When creating extensions from foam blocks, the outer walls need only decorative cladding.

- The external walls can be plastered, the solution sticks well to the blocks of foam concrete and does not crumble during the operation of the building. A good option is to finish building siding. It all depends on how the external coating of the structure will be combined in style with the main structure.

Interior decoration is made, as in an ordinary house. A plaster layer is applied, which is then puttled for painting or wallpaper. Consider the interior decoration options with drywall or wooden panels.