When choosing a kitchen set, special attention is paid to the countertop - this is its main working surface. It is subjected to the greatest load with the active activity of the hostess. In addition, the countertop is considered the “face” of the kitchen, its shape and color should correspond to the interior of the room. Artificial stone models are in great demand - they have all the properties necessary for the working surface and look great in any interior design.

Content

Artificial stone countertops

A countertop made of artificial stone or the top of the kitchen furniture is a stove fixed on the floor modules of the headset. It happens both monolithic, uniting tables and cabinets, and consisting of several elements.

The thickness of the top depends on the desire and financial capabilities of the owner of the kitchen. It varies within 2-13 cm and its cost depends on this parameter. Buying a tabletop made of artificial stone of slight thickness does not mean to purchase a product of poor quality. In this case, the stone is glued to a substrate of MDF or plywood and most importantly - the reliability of the frame and the strength of its connection with the cladding.

The width of the product usually corresponds to the parameters of the modules, but you can order a countertop protruding outside the facades of the kitchen set.

There are two types of composite materials:

- acrylic stone;

- agglomerate.

Acrylic stone

Acrylic stone is made from natural mineral filler. The binding material is acrylic resin. About 2/3 of the total composition of the stone is occupied by mineral fillers.

For the first time in the market, acrylic stone appeared in 1966. It was released by Dupont and for many years the right to make material belonged only to it. The Corian brand, under which artificial stone was produced, is considered the most famous and in our time. Sometimes people believe that the so -called any acrylic stone. But there are already many other manufacturers and, accordingly, other names of this material: Staron, Bitto, Montelli, Tristone, Hi-MacSB, Diamant, etc.

In our country, kitchen counters made of artificial stone are produced relatively recently, but the material of domestic manufacturers has a more democratic price. In terms of quality, it is not inferior to foreign counterparts.

Like any materials, acrylic stone has certain advantages and some disadvantages.

Advantages

- Strength - tops from acrylic composites are durable and withstand active operation without special negative changes in appearance.

- Stability resistance.

- Lightness in care - the countertop is perfectly washed with soap solution.

- The structure of the material - the incorrect surface is pleasant and heat to the touch, does not absorb liquids and oils.

- Large color scheme of tops.

- The possibility of restoration of countertops - scratches and small chips are easily polished even by ordinary fine sandpaper. More serious damage is also easily repaired at home. To do this, use a grinding and polishing machine.

- Acrylic stone flexibility. Under the influence of heat from the material, they create a variety of counterattacks of the tabletop model.

Despite the fact that the dark shades of countertops look stylish and rich, the defects that appeared during operation are more noticeable. On light products, scratches do not appear so quickly, especially if the products have a pattern of large and medium fraction.

Flaws

- The appearance of scratches with the active use of the countertop.

- The possible appearance of traces from very hot dishes - the acrylic stone negatively reacts to high temperature.

- The use of too hard washcloths and abrasive means threatens the appearance of scratches on the product.

Anglomerate countertops

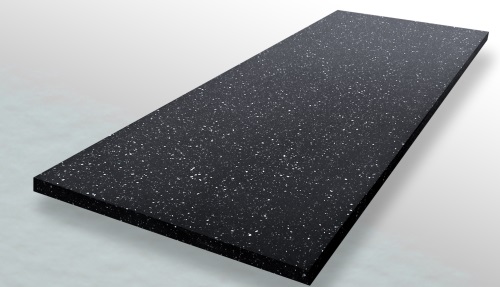

The agglomerate, in comparison with the acrylic stone, is much closer to natural material. Its filler occupies 90% of the total composition of the material. As a basis is a crumb of natural stone, and sometimes even its whole pieces. It can be marble or granite, but most often quartzite is used for the manufacture of kitchen tops. 10% of the component of the agglomerate is occupied by dyes and polyester resins. Outwardly, it looks like a natural stone.

The advantages of the agglomerate

- Strength - countertops made of agglomerate is more reliable than natural material and are able to serve for a long time with the most intense use.

- Stability resistance.

- The surface of the countertop does not absorb oil and water.

- Heat resistance (up to 150ºC).

- Without consequences, the use of abrasive agents transfers.

- The appearance of the agglomerate resembles a natural stone.

The disadvantages of the agglomerate

- The length of the continuous top is a maximum of 3 meters. It is possible to make a larger artificial stone countertop, but it will be with the seams. It should be noted that they are almost invisible - the joints are very well locked.

- The material is not amenable to restoration.

- The countertops are as cold as a natural stone to the touch.

- Topa from the agglomerate is harder than acrylic products.

- The material does not have flexibility. This limits its use in exclusive projects.

- The price of a countertop from an agglomerate above its analogues made of acrylic and natural stone. This is partly due to its more expensive installation in comparison with the acrylic product.

The undoubted advantages of artificial stone of any kind include hygiene. The smooth surface does not allow bacteria and mold - pollution from it is easily removed with soap water.

Count of artificial stone, the countertops not only organically fit into the general view of the headset, but also help maintain the perfect order in the kitchen. This is facilitated by the absence of seams and smooth transitions. They are beautifully cleaned, completely silent and resistant to corrosion.