A stone countertop gives the interior of the kitchen of solidity. She is beautiful and practical. At the same time, natural stone is very expensive. A good alternative is an artificial stone. Consider in this article how to make a countertop made of artificial stone with your own hands.

Content

Artificial stone? What is it?

What is an artificial stone? This is such a composite material that contains:

- fillers;

- mineral pigments;

- polymer resin, which connects all this.

The type of resin is determined by the type of artificial stone. Resins are most often used:

- Acrylic. This is a sheet artificial stone. He does not withstand very high temperatures - only up to 180 degrees C, therefore, using it in the kitchen, you need to observe precautions and not put a very hot dish on the countertop. A good place for him is a bathroom.

- Polyesh. Artificial stone with a polyester base. It is able to withstand the temperature of up to 600 degrees C. This material is available in the form of individual components from which a liquid suspension is prepared. It is either applied to the future countertop, more precisely on the basis from the chipboard, or the liquid stone is poured into the shape.

The advantages of artificial stone

Artificial stone is not the last place among finishing materials. Of the advantages can be called:

- relatively low price;

- high mechanical strength;

- moisture resistance. Due to this, no spots from tea and coffee on the surface are fixed;

- lack of pores;

- lightness in care;

- resistance to high temperatures;

- a variety of design solutions;

- environmentally friendly;

- the ability to take any form;

- there is no radiation background;

- in acrylic artificial stone, the color scheme includes up to 100 shades. In liquid - up to 120.

Making countertops made of artificial stone

If you are familiar with the carpentry, firsthand, then you can make a countertop made of artificial stone yourself. To get to work, you need to equip a small workshop, and besides, get:

- a sheet of artificial stone. Sheets that will offer you in the store usually have dimensions of 3.66x0.76 m and a thickness of 12.0 mm. There are also very thin sheets - from 3 to 6 mm;

- a substrate in the form of moisture -resistant plywood 30 mm thick. Sometimes they use fiberboard or chipboard, but this is not a very successful solution-swelling due to moisture, they are able to destroy the sheet artificial stone;

- two -component glue. On average, for one sheet of artificial stone, glue is required up to 150 ml and better in the tube;

- pencil and ruler.

A set of necessary tools

The manufacture of countertops involves the presence of a large list of tools and devices, which includes:

- grinding machine;

- lobby;

- disk and end saws;

- orbital grinder;

- drill;

- vacuum cleaner;

- cutter, but keep in mind, not any, but only of excellent quality;

- adhesive gun;

- milling mill;

- mills equipped with carbide blades;

- guide tire;

- devices for making measurements.

Process

When using artificial stone, the technology for manufacturing countertops, consists of a number of operations:

- We start with thorough measurements of the place where the countertop will be installed.

- Having thought out everything to the subtleties, we make a cutting card or drawing.

- We cut an artificial stone into the necessary elements:

- actually countertop. Its standard dimensions: length - 0.76 m, width - 0.605 m;

- strips for processing ends with a height of 3.5 to 3.7 cm; -preferential skirting boards or sides, the height of which is 3-6 cm. These sizes are only recommended, and you can choose others.

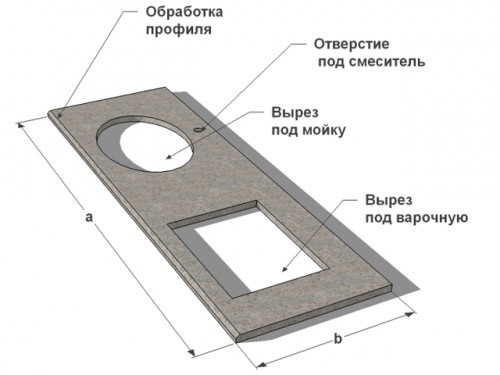

- Using a milling cutter, we end the edges of the workpiece and the contours of the cutouts for the sink and the hob.

- We process the profile, for which we turn the workpiece of the countertop to the wrong side up and using the milling cutter, we perform the groove under the edge. Its depth is 0.2 cm.

- We cut the strips from plywood with a width of approximately 7 centimeters for the formation of the frame, and if the thickness of the sheet of artificial stone is minimal, i.e. 3 mm, then the frame is cut out continuous, otherwise sufficient rigidity will not be provided.

It is important not to forget: The edge is installed on a clean surface, so conduct degreasing using alcohol or acetone.

The final design of the countertop

Further work on the countertop consists in gluing the edges and a frame from the plywood:

- we take a tube with two-component glue, equip it with a mixer, squeeze it into a plastic bag, mix, then cut off the tip of the bag and squeeze the glue on the edge or 2 mm groove;

- the countertop with the edge is squeezed with a clamp. Since the glue dries very quickly, we do everything promptly;

- after solidification, we clean the adhesive with a chisel;

- on the perimeter of the workpiece, we glue the stripes cut out of plywood with silicone glue, forming a frame lagging from the edge by 0.2 cm;

- if the countertop has a M-shaped shape, then in a place where 2 elements are joined, a strip of plywood is also glued as a stiffener;

- clamp the structure in the clamp and leave for 7 hours;

- the remains of silicone are removed with a chisel;

- on the site where the plywood frame is 2 mm behind the edge, we also apply silicone and smooth until the level of the frame and silicone coincides. For leveling, a milling cutter with a lower bearing is used;

- grind the plywood using a grinder;

- by placing the countertop face up, round the edge, using a milling mill;

- the places where there are cuts under the hob and washing, on the back is amplified by gluing the second layer of artificial stone;

- grind the surface of artificial stone to half a meter;

- it remains to be rounded by the parietal side and the countertop can be installed.

The option of manufacturing a simple rectangular countertop is described. When performing an L-shaped countertop of artificial stone, the processing technology of the ends is slightly different: the ends are milling mirror.

Mirror milling ends

The L-shaped countertop has two elements and they join in a straight line. To perform such a docking, both elements need to be milled at the same time. This is called mirror milling. It is performed in order to make the junction of adjacent details as invisible as possible.

The entire process of manufacturing a countertop made of artificial sheet stone is shown in this video material:

DIY liquid stone

Liquid stone in the interior looks very elegant. If you can’t allocate enough means to buy finished shape and liquid stone, then try to do it all with your own hands.

We make liquid stone ourselves

To do this, we make a stock of components for liquid stone:

- plasticine;

- fiberglass;

- pastes of different colors;

- chemical resin;

- filler;

- hardener;

- acetone;

- calcinitis;

- epoxy gelcoat transparent;

- thermal mushrooms;

- you will also need sheets of wood and fibrous.

Having mixed all the necessary components, we get a liquid stone. Now we have to decide: which of the 2 options we will make a countertop.

Option No. 1 - direct method

This method is fast and not very laborious:

- after all the necessary measurements, we cut out a workpiece of fiberboard or chipboard;

- we prepare the mixture that we will spray, for which we take 60% of the gelcoot, 40% filler, 1% hardener;

- with the use of a pistol, liquid stone is sprayed to the workpiece. The thickness of the layer is approximately 0.2 cm;

- dry the product, and then grind.

Option No. 2 - reverse method

For this method of time it takes more, but we win due to the smaller consumption of materials:

- previshes make 2 pcs. from the fiberboard, at the same time, in comparison with the finished countertop, they are 5 mm more along the entire contour;

- glue the blanks, draw and cut the hole under the sink and put them on the table;

- we cut out strips of chipboard or plywood and with the help of a heat mum, we fasten along the contour of the workpiece, which in this case serves as a template for obtaining a matrix, installing them on a rib;

- we take out the workpiece and cut off 5 mm allowance;

- we mark the place where the sink will be;

- we take plasticine and cover the gap between the sink and the table;

- the place where the edge of the countertop is planned is also coated with plasticine, and then they are given the necessary shape by using a special template;

- we process the matrix inside with a dividing wax or other dividing composition and wait 15 minutes while it is absorbed;

- on all surfaces of the matrix we spray a liquid stone;

- after 0.5 hours, the composition will harden and we place fiberglass, the purpose of which is to increase strength;

- the queue of soil filling was suitable, which includes a resin with an accelerator (6% of its mass), 1.5% of the amount of resin of the coloring pigment, 80% calcite and 1% hardener from the total weight of the solution;

- place the workpiece of the countertop in the matrix and evenly pressed on top, removing excess soil and air;

- we withstand 1.5 hours. During this time, the soil will freeze and the load is removed;

- we apply another layer of soil on the countertop;

- we cut the edges;

- we process the surface.

Please note: per 1 sq. m of the countertop requires 8 kg of soil, of which about 5 kg is consumed at the 1st stage and about 3-in the second. A mixture of liquid stone for this area will take approximately 3.5-5.5 kg.

And here is another way to make countertops made of artificial stone, and the liquid stone itself is obtained from available materials.

We make a form

The contour of the future countertop depends on the form we have made, so we approach the issue responsibly:

- we measure the installation site of the countertop, providing holes for the sink and stove, if they are there;

- we make strong racks for the base. Everything should be durable, since liquid stone is heavy material;

- as a base, take Crinospan - a sheet of chipboard, covered with a polymer film. The countertop will stick to a simple chipboard and it will be impossible to remove it;

- we fasten to the base of the bar, both longitudinal and transverse in size of the future countertop;

- in the resulting form, we insert the forms for the parts that will be mounted in the countertop: washing, hob panel;

- in places where there will be a crane, a mixer or other plumbing, the countertop should be thinner, so we fasten small wooden cubes there;

- we smear the corners of the shape, twisting them slightly.

Cook the mixture

To get cheap liquid stone, we take:

- cement not lower than M400 - 1 part;

- 3 parts of sand;

- 1 part of the water;

- color.

We mix everything in a suitable container.

Start the manufacture of countertops

So that the countertop made of liquid stone is strong, we observe the following technology:

- on the base of the form, place a reinforcing grid;

- we introduce the mixture into the shape, trying to distribute it evenly. At the same time, we remove the air from the mixture using a vibration grinding machine or at least a punch, in extreme cases. This is the first layer;

- we reinforce with a metal wire on top of the first layer around the perimeter of the shape;

- we spread the rest of the solution, equalize and let the product dry. Time until completely dry for different mixtures differs and sometimes can last 3 weeks;

- we take out the finished product from the mold;

- grind the front side, grind the sharp edges;

- having polished well, we rub the plane of the countertop, giving it a glossy shine.

Installation of countertops

Installation of artificial stone countertops on a kitchen base is not so simple, because it has a great weight, which means that one cannot cope with one.

Inviting assistants:

- remove the countertop from the desktop, place it in the right place and fix it;

- we perform holes for plumbing;

- install the sink and the hob;

- we wipe the finished design.

Manufacturers of artificial stone

Having gathered to make a countertop made of artificial stone, you will definitely ask yourself: - And which composite material is better to buy? Consider the advantages and disadvantages of the material produced by different manufacturers.

Montelli and Corian

Manufacturer from America Dupont (Dupont). Materials under this name have the following qualities:

- durable;

- racks to bacteria, pollution;

- homogeneous;

- the color palette is wide;

- seamless gluing;

- the price is relatively low.

Tristone acrylic stone

It is produced by a company from South Korea Lion Chemtech. Several collections are available:

- “Classic” is plain tones;

- "Romantic" - only natural colors;

- "Baroque" - the material includes natural and transparent particles;

- “Byzantium” is an artificial premium stone, has a 3D effect.

Hi-MacS

The LG corporation issues. The stone contains:

- 70% of natural materials;

- the basis of acrylic resin;

The quality of the composite is high, the price is democratic. The thickness of the sheet is from 6 to 12 mm.

COLGran liquid stone (colragon)

Produces a liquid polyester stone of excellent quality and has:

- the color spectrum includes 150 colors;

- resistant to the formation of spots and scratches;

- easy to care. It is cleaned with conventional domestic means.

Repair of artificial stone countertops

Despite the excellent characteristics, sometimes there is a need to repair countertops made of artificial stone.

Types of possible damage

On the artificial stone countertop, in case of improper operation, the following damage may occur:

- scratches;

- cracks;

- bloating;

- white spots from hot dishes;

- chips.

Cracks, scratches and their elimination

If you are seduced by a low price and bought an artificial stone from Chinese manufacturers, then a crack may appear due to non-compliance with manufacturing technology. Eliminate the crack like this:

- we clean and degrease the crack, we expand it a little;

- we introduce glue into the formed channel, consisting of two components - the same as used to glue the edges;

- grind and then polish the surface.

Visually, the surface of the countertop will not differ from the new, but still the strength characteristics will deteriorate, therefore:

- buy only quality material;

- clearly observe the technology in the manufacture of countertops.

Not deep scratches, but also some spots are removed by grinding, using sandpaper of different grainisms, starting with the largest and ending with small. Subsequently, these places are polished with a felt nozzle dressed on a drill. This repair is possible if a fairly thick sheet was used for the countertop.

Elimination of bloating and spots

If there are such defects on a thin sheet, then:

- we cut a damaged place using a milling mill for this;

- from the remains of sheet artificial stone, we cut out the patch, choosing the color;

- lubricate with glue and insert the patch into a damaged place;

- we grind and grind the joints.

To find out how to eliminate the chip on the artificial stone countertop, watch this video: