The need to make a woodstone made of wood with your own hands can arise for various reasons: you want to make a table with original sizes, update old furniture or just practice furniture. Be that as it may, everyone can build a countertop if desired. However, in addition to the desire to have a clear instruction, carpentry tools and a few skills in working with wood. In this article you will find all the necessary instructions for assembling a countertop with your own hands.

Content

Choosing wood

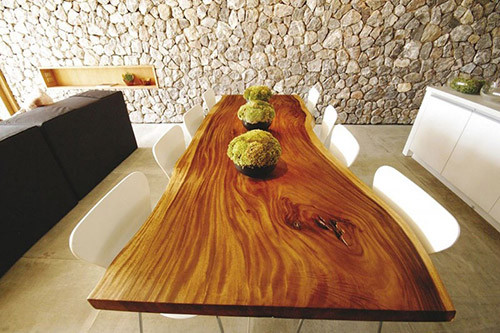

Often in the manufacture of furniture, prefabricated wooden countertops and made of a carpentry shield are involved. The woodcs from the wood array are very beautiful, durable and durable, and therefore are quite expensive, therefore they are used to assemble premium furniture. However, for work at home and without special skills, whole pieces of wood are not suitable, since they are very difficult to process.

Regardless of the type of design that you plan to do, you must first choose the right wood. The table should turn out to be strong and resistant to mechanical influences, especially when it comes to kitchen furniture. If you want the countertop to serve you for many years, preference should be given to solid breeds: oak, cherry, cherries, tiku or nuts. These are the most suitable trees for creating tables. There are more firm rocks, but they are very long and difficult to process, and the cost of some exceeds the price of finished factory furniture. In addition, too solid wood can be dry out or swell from temperature and humidity drops. The previously listed types of trees not only have sufficient strength, but are also able to effectively withstand various external influences.

Tools and materials

Depending on how you will make a countertop, you will need various tools. So, if you make a countertop from the carpentry shield, you will have to get a fuganka - a long shirt with which the finish (smoothing) of the surface is carried out. The shield method allows you to make strong and durable furniture of large sizes.

The best option for a self-taught master is a fugitive machine. It can be rented, or if you do not have skills in working with such equipment - ask to process the workpiece of a specialist in the workshop.

So, what is needed in order to make a woodwood made of wood:

- automatic or manual milling cutters (if you plan to make a table for a summer residence that will stand out in the air);

- jointer;

- hacksaw, perforator;

- set of drills;

- hammer;

- fasteners (nails, screws);

- pliers;

- elevator paper of different granularity (from No. 3 to No. 0);

- flight;

- clamps;

- wood (boards);

- carpentry glue;

- morilka (if you tint the wood);

- antiseptic impregnation (to protect the tree from pests);

- varnish or paint;

- flat brush.

Useful advice: choose boards of the same thickness if you want the countertop to be strong. Before assembly, all wooden elements should be dried, otherwise the countertop is deformed over time.

Before starting work, select the type of connection of the elements of the future countertop. In some cases, you may need additional wooden rails and fasteners.

Methods of compounds

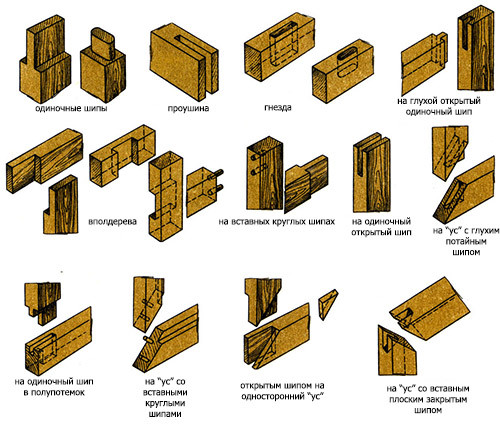

There are several ways to connect wooden parts in carpentry. Depending on the chosen method, the assembly technology of the countertop will differ. Basically, for this work, knitting and rallying are used using carpentry glue and wooden dawns. This or that type of connection for the manufacture of the shield is selected depending on the functional load of future furniture. The easiest way is to rally. It implies gluing elements with each other with edges processed on a fuganka. To give the shield a lot of stability, at the ends of the boards you should choose a groove and a comb or a quarter so that they go into each other. Also, elements are also rafted on the insertion bar of plywood, mounting it in specially prepared grooves.

You can also join the boards of the countertops to inserted spikes, the diameter of which should be half less than the thickness of the board, and the length-exceed the diameter by 8-10 times. Install such round spikes every 10-15 cm.

Consider the basic examples of fraining wooden elements:

- The end on glue - such fastening of the boards does not give high strength and applicable only in cases where the bars have an enhancing fixation on the edge or plate. To strengthen the scraping, you can apply the connection to the "mustache". For this, the ends of the elements are fastened at an angle of 45 °.

The stepped connection to the “mustache” allows you to increase the area of \u200b\u200bfasteners, making it more durable.

Sowing of a non -core is one of the most common techniques used in the middle and angular mounts. To increase the density, make the boards of the boards under a protracted lock on the ends - then a wooden countertop will withstand any load. - If you need to connect the boards over the entire length, use a wedge or straight spike with carpentry glue. Shipping compounds are used to fasten the boards with ends or end and middle at an angle. To do this, you need to select a spike and eye, a spike and a nest or a groove and a comb in details, that is, two parts, fitting with each other like a puzzle. Spikes can be flat, trapezoidal (swallow tail), round or gear. The design distinguishes integral spikes that are made at the end of the boards, as well as insertion. The latter are called dowels and pass along the entire length of fastened elements. The spikes have side edges (cheeks) and shoulders (cut ends of the bar). If the spike nest is open from 3 sides at the end, it is called eye.

If you make the middle connection, choose the depth of the spike nest more than the length of this spike by 2-3 mm to leave a place for excess glue. At the ends of the spikes, cut the chamfers - so it will be easier to enter the nest, and the glue will almost not be driven to the implements. The denser the docking, the stronger your countertop will come out. - Insert round spikes are most often used, since this is a simpler method of angular connection. At the same time, they provide the same strength as if you chose the spikes in the end of the boards with your own hands. In the image below, you can see examples of studs:

Fasteners for countertops

To ensure additional strength of angular stud joints, wooden bastards are used. These are small details with a cone -shaped end, which are coated with glue and inserted into specially prepared holes. Such a wooden nail is installed perpendicular to the sidewalls of the spike, as a result of which it passes through the entire spike and eye. So that the sticking ends of the nagel does not interfere, they are cut off by flush with the surface of the product.

In some cases, it can not do without the use of ordinary nails. It would seem that it could be easier than getting a nail, but if you want to get a beautiful and even countertop, you need to know how to do it correctly:

- If you work with a solid wood, clog nails into pre-drilled holes with a depth of 0.5-0.6 of the length of the nail.

- If you fasten the details without piercing them through, then the distance between the mounts should be 15-20 lengths of the nail; If the fastening is through with a bend, increase this distance by 2-3 times.

- With through punching, the nail should be longer than the thickness of the boards by a third.

- Bend the nails perpendicular to the fibers of the wood, otherwise the boards are cracking. For bending into the castle, take an unnecessary trihedral file to give a frozen shape with a nail and then drive it into a tree.

- To increase the strength of fasteners, drive nails under a slight inclination. If you make a carpentry shield with an overlay, drive them in a checkerboard pattern.

- Cutting the blanks on the weight, substitute a large hammer from below.

How to make a carpentry shield

Regardless of the selected method of connection, before starting to assemble the carpentry shield, the wood should be prepared. This implies work with a fuganka, grinding, antiseptic treatment. If you plan to tint the countertop and open it with varnish, this must be done after assembly.

The most elementary way to collect a furniture shield is to glue the elements. And so that such a countertop serves more, the mounts must be strengthened in one of the above methods, that is, choose a spike and a groove. In this case, the spike will be located on the end part of the countertop, and the groove at the end of the head. As an alternative - from below you can glue the transverse strips that will enter the grooves.

We will consider the method of fastening the crest-Paz, since it is more reliable than the crest-chip. The main difference is the uniform distribution of the load, so that the attachment places do not become potentially vulnerable points. To make grooves and crests, use a manual or automatic mill.

If you want to attach the rail from below, first attach the boards on the edges, and then make grooves with a cutter. In thick boards, the sizes of the groove are usually 10x10 or 15x15 mm, and in thin ones - from 6 to 8 mm. This factor also depends on which cutter you use.

When working with a milling machine, always use a flight - it will help to put the boards as accurately as possible. Reiki can be done independently or bought ready -made. The width of the rail depends on the dimensions of the countertop, and the thickness is on the size of the chosen groove (the rail should perfectly enter it). Instead of a rail, you can take an oil plywood or a piece of MDF from 6 to 12 mm.

If you need to make a countertop for a summer house or apartment in the style of a hunting house, it is better to take a dodgy board. It should be collected according to the same principle as an ordinary carpentry shield, only for the edge under the groove is used a spoon. Fix the boards, fastening the transverse beam from below with self -tapping screws. So you can quickly build a massive, strong and rather rude table, which will give the highlight of the interior and decorate the country veranda.

How to make an option

Any team of the countertop needs a background - a protective edge that goes along the entire perimeter of the structure. For the block, you will need 4 bar made and solid wood, for example, birch, walnut or beech. It is better not to use oak, since it is too heavy. For a countertop 134x80 cm, make 2 parts 140 cm long (with a small margin) and 2 - 85 cm each.

Before the installation of the hull bars, select a one -sided comb along the entire perimeter of the countertop. To do this, use a manual mill or a circular saw (it is recommended to put discs for working with a laminate).

How to make a comb with a circular saw:

- Fix on the guide thick sheet of chipboard, put a height of 10 mm and the same at a distance from the guide along the external divorce.

- On the opposite side, put a bar 33-34 mm from the guide and tightly hold it with clamps. This will be a kind of stop for the design.

- Put a sheet of chipboard on the edge and pass the first side of the quarter, removing the unnecessary part of the wood.

- Complete the cuts around the perimeter.

- Remove the stopper-bruck and make cuts from the side of the facade. As a result, you get a spike 22 mm wide.

- Make grooves on the inner ends of the edging bars, calculating the depth in accordance with the thickness of the spike. To do this, use a mill and a quarter cutter with a support bearing. When you install the salary on the rib, make sure that the details protrude behind the bar from the DSP by no more than 1 mm (ideally, elements should go on a flush with each other).

- It remains only to mark the details of the edging in length and cut the ends at an angle of 45 ° for a beautiful connection.

- Glue the slats and pull them with clamps until the glue is completely solidified.

- To strengthen the mounting, pull off the lining and the countertop with self -tapping screws, screwing them slightly obliquely and fingering the hats in wood. These places can then be covered with putty on wood to match the color of the breed.

If you make a wooden countertop for the kitchen, glue the plastic panel on top to protect the material from mechanical damage and humidity. In other cases, you can cover the surface with paint, varnish, make beautiful decoupage or apply decorative painting.

We hope that this article helped you figure out how to make a woodwood made of wood. Do -it -yourself furniture is always more appreciated than the one that was bought in the store. In addition, taking control in your own hands, you can make tables of atypical configurations, fitting them as well as possible into the interior.

Finally, we suggest you watch an interesting video about the manufacture of a round woodbuilder: