Plastic bags are becoming increasingly popular in houses. They serve as a rather reliable protection against wind and cold, the penetration of pollution and noise from the street.

Content

A separate variety is sunscreen, which can significantly reduce the percentage of ultraviolet rays in the room. To protect your house from an excess of the sun in the summer, you need to know how the sunscreen provides a similar effect.

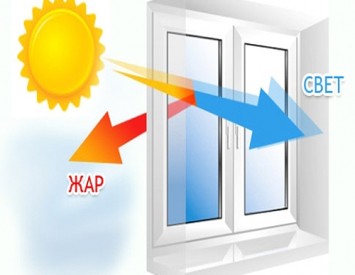

The principle of operation of sunscreen

The main goal for which sunscreen is used is a decrease in the flow of sunlight, which reduces the effects of excessive ultraviolet radiation and indoor temperature. As a rule, such glass is distinguished by a different color shade: grayish or greenish.

First of all, the absorption of solar radiation occurs due to the tinting layer. As a rule, it is added either during the introduction of metal oxides into a viscous mass, or later, by applying a film or spraying to a finished surface. Thanks to the tinting light absorption, a tangible decrease in temperature occurs: even in the presence of a single-layer double-glazed window with sunscreen, the temperature decreases by an average of 3-5 ° C.

Such double -glazed windows are made of reflex glass with reflecting the effect, or from hardened by heat treatment.

Even with direct exposure to sunlight on glass, you should not be afraid of its excessive overheating. Such a danger threatens those glasses that have an excessively dark tinting film.

According to the principle of operation, glasses are divided into two groups:

- reflecting,

- absorbing,

The reflecting layer is applied in the production process using spraying, or at the time of installation or after, by pasting with a film that will provide good protection of the glass from the sun.

The production technology of absorbing glasses is more complicated. Once on the surface, the light is multiplying and divided into spectra. Ultraviolet remains inside the double -glazed window, and the rest of the light flows pass into the room.

Sunscreen production technology

Two methods for obtaining glass are used:

- furio,

- float.

OP technology Furio's method involves rolling a glass mixture through rollers, after which the obtained sheets are moved to the cooling chamber. A similar method managed to become obsolete morally, since, unlike float technology, it involves a significant percentage of glass surface defects.

According to the technological process, the Float method is more preferable because it has the following advantages:

- the absence of the need to modify the surface of the glass,

- small percentage of marriage of finished products,

- high performance,

- optical defects on the surface of the glass are practically absent.

According to the floic meter production of sunscreens, the molten mixture having a strip shape enters the container with tin. Due to the fact that tin has a higher density, the glass does not mix with it, but is on the surface, cools and divides to a perfectly flat surface. Next, the glass chilled to 600 ° C enters the furnace in which a layer of metal dioxide is sprayed onto it. After that, the glass is gradually cooled and checked for defects. In the case of their detection, during cutting, such areas are cut out and used again, in the next batch - due to which, the production of glass is a non -waste process.

Types and characteristics of sunscreen

Relatively recently, as sunscreen on the market, exclusively varieties with tinting were presented. They are inexpensive, but have a significant drawback: the higher the stopping ability, the darker the glass, and, accordingly, it passes less than the light. As a result, on a cloudy day or evening time, the illumination of the room will leave much to be desired. Exceptions are those varieties of glasses that I have a greenish tint.

Of the advantages, it is necessary to highlight the throughput indicators, which make up 70% for sunlight and only 30% for infrared and ultraviolet flow.

But there are also their shortcomings: tinted glass heatily heats up and are afraid of uneven cooling.

The second effective solution to the problem of passing solar radiation will be the use of colorless sunscreen in the double -glazed window, the coating of which allows you to reflect ultraviolet. This method is based on the presence of particles of impurities of titanium oxide and chromium. The mixture covers the glass with the thinnest film, while the metal reflects sunlight well and, most importantly, the excess ultraviolet radiation “beat off”, and the glasses themselves continue to pass sunlight and do not heat up. The disadvantage of the method will be its cost.

A combined variety is gaining popularity, a distinctive feature of which is the appearance: a silver mirror surface. The technological process of manufacturing such a coating does not have significant differences: the workpiece is placed in the furnace and at a temperature of 650 ° C, four layers of coating from metals oxides are applied, then they are hardened. In the end, the glass is covered with silver spraying and allowed to cool.

The specified variety, in addition to the high indicators of the reflection and absorption of ultraviolet radiation, is also characterized by an excellent degree of thermal insulation, which is very relevant in winter. A pleasant addition will be a beautiful aesthetic appearance and the absence of the need to purchase curtains or blinds - since the combined reflex glass looks like a mirror and does not allow us to consider what is behind it. From its minuses, it is important to note the complexity of the manufacturing process, as a result of which the final price for the double -glazed window is also determined. More often, such glasses are used in buildings where invisibility is provided to visitors and working people. A good example is banks and office -type buildings, as well as bars and restaurants. Another advantage of choosing such a glass of glass will be its resistance and strength to mechanical influences.

Less commonly there is a special type of sunscreen glasses - these are photochromic glasses that received the nickname "chameleon". They demonstrate an interesting ability to change the percentage of light and heat access to the room under the influence of sunlight. With an excess of ultraviolet radiation, such glasses are darkened, in cloudy weather, on the contrary, the surface of the surface comes to normal. Such a variety is obtained when silver and cesium are added to sodium -reassador -diligent glass. Of course, the final price of such double -glazed windows is able to upset ordinary consumers, but for household needs there is an alternative - a photo chromium sunscreen, which is manually applied to any glass and found the use of both buildings and car windows. Moreover, the price of a tower meter of such a film is quite modest - only $ 4, which allowed it to be widespread among motorists.

The use of sunscreen

First of all, glass is used specifically to protect from the sun. Any variety of glasses used can significantly reduce the effect of ultraviolet radiation on the environment located behind the glass. For example, furniture and curtains can easily fade, being under the "sight" of the sun. Glass is suitable for absolutely any use: its varieties are installed in winter gardens and greenhouses to protect plants from excessive sunlight, in high -rise multi -storey buildings, in double -glazed windows of private houses and apartments. Moreover, any person at least once in his life wore sunglasses, the glasses of which are covered with a tinting film, or have shading impurities in their composition - therefore, the favorable effect of the use of such glasses is noticeable to everyone.

Modern glasses are able to shadow natural light, but at the same time provide comfort in the following directions:

- Thermal insulation of the room. There are many varieties of finished double -glazed windows and tinting films on the market, whose task is to protect the glass from the sun, while the internal heat in the room is reflected from the glasses and persists longer.

- Due to sunscreen, general energy efficiency increases. Properly selected sunscreen in the glass -glazed window can lower the cost of air conditioning and heating the internal space of the room. The difference is significant compared to simple glasses and double -glazed windows.

- A solid coating applied is durable and high mechanical strength.

With your own hands

Do -it -yourself sunscreen is especially relevant if the windows overlook the south. Close to close with curtains or blinds not the only way out when it is quite possible to independently glue the sunscreen on the glass. There are several varieties of films that are optimally suitable for this task:

- Standard tinted. Designed for simple protection from the sun. The room, in the presence of such a film on the window, does not heat up so much in addition, there are no glare from the sun on the screens of TVs or a computer.

- Mirror film. It is an excellent solution for the case if the neighboring house is located in the immediate vicinity, and there is no desire to constantly keep the curtains detached. Such a film on the glass from the sun will provide unilateral visibility when it is impossible to view the room outside. It is important to remember that a similar effect works in the daytime or when the degree of light on the outside is brighter than inside. When the light is turned on, the mirror effect disappears.

- Matte film. It is used for those cases when it is necessary to limit the transparency of the glass. As a rule, for internal glass partitions in order to reduce direct visibility. At home, the film found its use in door stained glasses and glass partitions of showers in bathrooms.

- Protective film. It has high resistance to mechanical damage. Its use is important in the children's room, since some varieties allow you to make the glass unconscious, which is important if the child due to careless actions will strike the glass. Even in case of destruction, glass covered with a protective film will not fall into fragments.

Since there is a large assortment of filming films on the market, and their price is available to any consumer, the conclusion is obvious: the sunscreen for glass represents tangible competition for finished double -glazed windows, since it does not require special skills for its gluing. In the event that the decision is completely used, it is worth preparing auxiliary tools in advance:

- chancellery knife,

- a spatula for alignment. The spatula should be used rubber, since the metallic is easily caused by damage to the film,

- a spray gun with a prepared soap solution for the finish adjustment of the film. Simple water in this case will not fit, since it does not have the proper effect on the adhesive.

The process of gluing must be divided into several stages for more convenience:

1. Preparation for work:

- a roll is rolled on a flat surface and the required amount of the film is measured;

- with the help of a stationery knife, the site required in size is cut out, while it is important to leave around the perimeter a margin of 1-2 centimeters, which will be cut off later;

- the surface of the glass is cleaned from contaminants and dust using cleaning agents on an alcohol -containing base, then it is wiped dry by the newspaper. Newspaper paper is better suitable for this work than a rag, since it does not leave stains on the glass.

2. When the preparatory work was over - it is worth moving on to the main ones:

- the surface of the glass is abundantly moistened with soap solution;

- the protective layer is removed from the film. It is recommended to perform this work with the assistant in order to avoid difficulties in gluing;

- using a solution of soap, the adhesive layer of the film is moistened so that it does not begin to arbitrarily stick to the glass during gluing;

- next, the film section is applied to the glass and carefully leveled with the hands and rubber spatula. A small dense roller is also often used. It is always necessary to level from the center to the edges in order to remove moisture from the edges of the film;

- the final stage of work is the accurate removal of excess film with the help of a stationery knife.

It often happens that the film as a result of damage or replacement will require removal, and in this case there will be difficulties. Some films are based on lavsan, which belongs to chemical materials, therefore, according to many experts, traces of gluing composition with great difficulty and not always completely, are removed even with the help of solvents and means for cleaning glasses. In this case, do not despair, but it is better to pay attention to simple tools. For example, it is enough to apply a fluor -containing toothpaste on the sponge and wipe it with traces remaining after the film. Then the back of the sponge, which has a rigid base, the glass is wiped for the second time and there are no traces. In addition, the most ordinary wet wipes are also suitable for this task.