The shield door is the most common type of door structure. Its popularity is due to a low production price. Such doors are quite reliable. However, there are several nuances that you should know about before buying a shield door.

Content

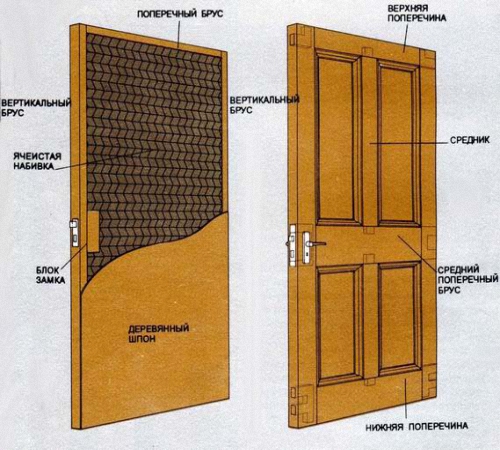

The design of the shield door

The traditional shield door consists of three elements:

- frame,

- filler,

- layers.

The frame is a rectangle assembled from solid or emaciated wooden bars. A groove is called a beam glued from individual boards. This option is more reliable, since it is not subject to a change in geometry due to temperature changes or changes in air humidity.

Additional stiffeners are installed between the upper and lower crossbars. The more there are, the stronger the door. The distance of 10 cm is considered optimal. With such an arrangement, the ribs will provide sufficient strength even for a very thin lining.

If we talk about the material, then most often the frame is assembled from pine, less often from birch. Given the design of the shield door, there is no fundamental difference between wood species, since the frame does not directly interact with the environment.

The filler is called the material that is installed between the stiffeners. The following types are used:

- toleled wooden board,

- minvata,

- foam,

- polystyrene foam,

- installation foam.

An unprocessed wooden board is very cheap. Therefore, in the simplest options, it is it that is used as a filler. Of the shortcomings- a large weight of the finished design, weak sound and heat-insulating properties. The rest of the materials are approximately the same in properties and price, so they do not affect the characteristics of the door too much.

Basically, the frame-shack doors are installed as interior, so their decorative value comes to the fore. The overlays are responsible for this.

Layers for shield doors

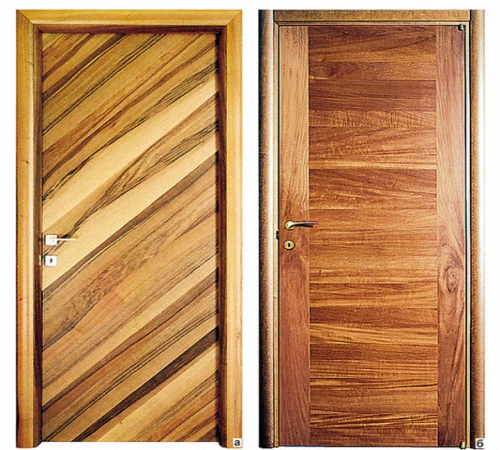

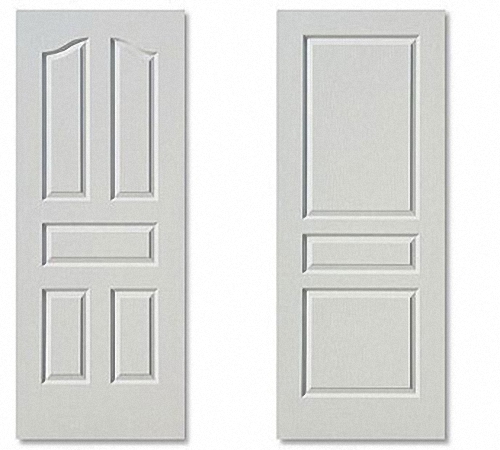

The shield door got its name due to the fact that its front and back sides were a flat shield without any excesses. Nevertheless, the designers stepped far ahead and created a lot of variations for any taste requests. Therefore, the shield doors are customary to divide:

- patterned,

- even.

Patterned shields consist of the base on which special decorative elements are pasted. Such a door looks much richer. In terms of operational characteristics, it is no different from the door with a flat canvas, but it costs a little more. On the other hand, any glue has the ability to dry out, so the use of patterned overlays in rooms with an aggressive external environment is not allowed. We are talking about:

- bathrooms,

- kitchens,

- cellars,

- balconies,

- children's rooms.

The last point has a slightly different nature. Since the overlays are glued, they poorly tolerate mechanical damage. This shakes the structure and leads to its breakdown. Children, especially at a small age, often like to throw toys. Regular door entering even soft plush products in a few years will lead to the lining is peeled off.

It is quite simple to fix it:

- it is necessary to completely clean the surface of the shield and the lining itself from the glue,

- remove the door from the loops,

- degrease the place of gluing,

- apply glue to the inner surface of the lining,

- glue and crush the overlay with a load of at least 10 kg.

But, it is much easier to use even shield interior doors. Since they will not need the repair. In addition, their cost allows us to make a regular replacement of the door if the canvas is hopelessly spoiled.

Material for linings on shield wooden doors

This is perhaps the most important point when choosing a shield doors. The following options are used in production:

- DSP,

- DVP,

- MDF,

- Plywood.

The wood-cutting plate is one of the most popular materials for linings. Especially in budget models. There is no need to talk about its advantages, and the shortcomings should be noted:

- the presence of formaldehydes and other volatile toxins,

- highs moisture strongly, which leads to irrevocable damage to the canvas,

- it has a fairly large weight and thickness of the canvas.

The wood -free plate is more reliable. Although in its manufacture, chemicals harmful to humans are used, in the finished product, their level rarely exceeds permissible norms. Since the wood fibers are much more slow than sawdust, the FEP is practically not afraid of moisture. In addition, a more viscous structure allows you to reduce the weight and thickness of the canvas. Another indisputable advantage - on sale there are hard -to -flammable varieties that are effectively used in refractory doors. DVP is more completely, but also has its drawbacks. This is primarily due to the structure of the plate. If you damage the shield, then it will gradually begin to crumble and crumble. The putty will solve the problem, but will ruin the appearance of the door.

MDF is a modified type of fiberboard. It has the same features, but compared to wooden -fiber plate, much lighter and thinner. In addition, the evaporation of chemicals dangerous to humans is minimized. This is the best choice for lining on the shield door.

Plywood - to put it mildly, controversial material. On the one hand, it consists of wood, quite light and thin. But it is important to understand that plywood is highly subject to a change in geometry, it sags, is dry, demanding on operating conditions and is not subject to repair, whether it is mechanical, chemical or atmospheric damage. Naturally, if you do not use the door, or it is placed in a rented office, an apartment for rent, on the cottage, then the choice will be quite justified by the price. For everyday use in your home or apartment, such overlays are not suitable.

Face coating of linings on the shield doors

Each of these materials has an extremely unsightly appearance. In order to give it attractiveness, decorative materials are used:

- veneer,

- melamine film,

- vinyl film.

The veneer imitates noble varieties of wood. Often, high -quality veneer is made directly from red, iron and other rare species of trees. Technically glued on the door shield, he is able to turn any door into an icon of style and luxury. Nevertheless, the requirements for gluing suggest a fairly expensive and powerful equipment. It is not affordable for most small manufacturers, so the veneered products quickly begin to lose attractiveness.

Larger enterprises prefer to use the melamine coating, since it is much cheaper than veneer. Melamin is a thin film from 200 to 4000 microns. which allows you to create almost any pattern on the surface of the shield. Most often, manufacturers imitate a tree or use a pastel gamut of colors.

A compromise between the conveyor and originality is a vinyl film. Unlike melamine coatings, vinyl allows you to use absolutely any color combinations from gloomy black, to dazzling ultramarine. Although most doors are made in one, maximum-two colors, with the help of vinyl it is easy to make a mosaic door or decorate it with some kind of pattern. To do this, you will have to make an individual order for the manufacturer.

Not so long ago, the so -called Canadian shield doors appeared on the market, the price of which starts from 600 rubles. Plywood is used as a lining in them, and the internal filler is completely absent. Nevertheless, they have one raisen - the white color of the coating. Designers effectively use this to create unique drawings on the doors. There are a lot of technologies, from ordinary drawing, to graffiti. The result is very original products. Naturally, their quality leaves much to be desired. Therefore, the finished picture is covered with several layers of colorless varnish. Such a simple solution allows you to protect the door from most negative factors. The only thing she will be afraid of is mechanical damage.

If there is no desire and time to experiment with art objects, it will be better to turn to trusted manufacturers.

Review of shield manufacturers

Consider the manufacturers of wooden shield doors in the order of increasing prices:

- BelwoodDoors is a Belarusian company founded in 1999. Exports goods not only to the CIS countries, but also in Europe. Offers very high -quality products, at a price of 1800 rubles. For simple models and from 2500 rubles. For more exquisite options. The lineup has more than 1000 variations.

- "Krasnoderevik" is a domestic company founded in 1993. Before the beginning of the two thousandth, the factory was engaged in custom -made doors. From 2000 to 2005, the competition “Hundred Best Products of Russia” won the competition annually. Now the company has reached a fundamentally new level of quality, fully complies with European standards. Product price from 2700 rubles.

- "European" - the history of the company began in 1999. Initially, it was engaged in the production of materials for the manufacture of furniture. Since 2006, the direction for the production of interior shield doors has been actively developing. The peculiarity of the products is that all the components of the doors, except for accessories, are made at the factory. This avoids marriage. Products comply with all domestic and European standards. The lineup starts from 5500 rubles. The price is attached to a guarantee for seven years, which is an absolute record for Russian manufacturers.

- Framir is a narrow -profile enterprise that is engaged in the production of venerable products. The rich model range and the highest quality was provided by the company popularity. Of the shortcomings, a bad distribution is represented mainly in Moscow and St. Petersburg. The price starts from 7000 rubles.

These manufacturers belong to budget models. If we talk about the price-quality ratio, then the choice should be stopped at BelwoodDoors. But to a greater extent, the choice of the door depends on taste preferences.

Model and VIP -class models are presented:

- Radadoors is a Russian manufacturer who has been actively conducting activities since 2005. By 2008, products entered the CIS market, more than 30,000 m is produced monthly 2 door leaf. Moreover, the quality of the product remains at the highest level. Price from 11,000 rubles.

- Dariano - the main plant is located in Khabarovsk. This company began work in 1998 and completely turned the creation of doors into art. A rich model range and excellent performance provided the doors with popularity. The production uses fairly expensive wood breeds, so the doors are really reliable and durable. Price from 14,000 rubles. The assortment has doors with a complex geometric design. As linings, a real tree is used. The price of such products starts from 30,000 rubles.

Various distributors, whether private sellers or construction hypermarkets, offer Italian, French, and less often Spanish manufacturers. Of course, their quality and external design do not cause any questions, but the cost is unreasonably high.