In industry and farm, it is often required to cut certain parts. There is nothing unusual in this if there are always the necessary tools at hand.

In this material we will talk about pipe cutting. It is worth saying right away that the pipes are very diverse. Accordingly, in some cases, you need to make a choice in favor of a particular method of cutting pipes.

Our main task is cut the pipe Thus, so that in the future it can be used. Often, the hosts choose completely inappropriate tools that damage the pipe connection. Thus, using damaged pipes is strongly not recommended.

The volume of work also radically changes, if we need to cut not a thin pipe, but a massive one.

Content

Features of cutting pipes of small diameter

Very often in the farm you need to cut a small pipe. Most often, their diameter does not exceed several centimeters. Fortunately, for cutting such pipes it is not necessary to use any complex devices, and even more so, grinds and machines will not be needed.

It makes sense to note that there are more and more different tools on the market that facilitate the once laborious processes. In this case, a pipeline is useful for cutting pipes. Now there are several modifications of this tool on sale. It all depends on the diameter of the pipes that we need to cut.

You also need to say in advance that there are cutters on sale that are able to cut large diameter pipes. Experts say that such a device is short -lived, especially if the pipe has a large thickness of the metal. Of course, it is advisable to shorten small pipes with a cutter. On average, such devices can be operated without problems for several years.

Small pipes cutting process

To cut the pipe, we need to fix it in the clip of the cutter and turn it out the handle of our tool clockwise. The cutting video should come into contact with the pipe. Next, another revolution is made, after which a distinct trace of the cut will remain on the pipe. If the circle is closed and has no visible deviations, you can continue the process.

Now we move the cutting handle by half the turn and move the mobile video to the pipe. You need to make sure that the cutting elements of the device entered the metal. Next, it is necessary to rotate the pipeline. This process continues until the tool completely cuts the pipe.

In order for the process to go smoothly and without the slightest problem, you can lubricate the necessary section of the pipe with oil. This will significantly reduce the metal processing temperature, and also accelerate the process itself.

If we are talking about cutting plastic pipes, then everything is much simpler than it might seem. Often, not specialized tools are used for this process, but, for example, large scissors for metal. There are also special cutters for plastic pipes that are very difficult to distinguish from ordinary scissors. In order to cut off part of the pipe, it is necessary to make a lot of effort, however, often the plastic products are very flexible and is excellent to cutting.

It is also worth saying that it is best to purchase products from authoritative manufacturers. Very often in stores you can find Chinese products in this area, and it is these devices that are called “disposable”, since such devices are unambiguously unsuitable for regular use.

The cost of cutters for pipes of small diameter is quite high. If the tool is needed for regular use, then it will become an excellent assistant. Otherwise, it is better to take a cut from someone for rent.

Cutting pipes of large diameter

Unfortunately, the above tools are no longer suitable for cutting pipes of large diameter. In industry, there are a lot of other devices that are characterized by high durability and reliability. In industries, many installations for cutting pipes are used almost around the clock, which indicates their practicality.

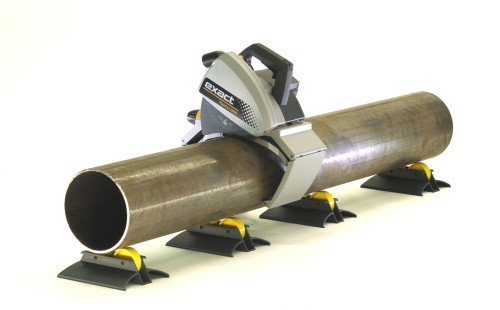

Cutting with a roller pipe cutter

Using a roller pipeline, you can cut a tremendous amount of metal products daily. The design of such a device consists of cutting rollers, as well as a holder, with the help of which you can cut the pipes, being at a certain distance from the process that is happening. Thus, in order to carry out the necessary work, it is necessary to make progressive movements up and down, until the pipe is resolved.

It is worth saying that this tool is common in industry, but as a device for constant pipe cutting, this is not the best option. The thing is that the cutting process here is quite long, and even time -consuming. But if the pipe metal has a small thickness, then there should be no problems.

Using a hacksaw machine

At enterprises where pipes cutting are regularly used, a hacksaw machine is often used. This is a fairly massive installation resembling a vertically milling machine, only a huge hacksaw is installed instead of the cutter.

In order to qualitatively carry out cutting, you need to fix the pipe and make sure that the hacksaw is directed in the right direction. It is worth noting that this installation is universal, since with its help you can cut not only pipes, but also many other metal parts.

Unfortunately, this installation has frank disadvantages. When cutting, a hacksaw machine leaves sharp edges that may turn out to be a serious barrier for further work. Also, if the pipe has a large diameter and a considerable thickness of the metal, the cutting process can drag on for a long time.

Cutting with abrasive tools

Most people have a grinder or some other abrasive installation in the farm. This is a great option that has practically no shortcomings. For cutting, it is quite reliable to fix the pipe and qualitatively cut off part of the metal products.

It should be noted that when using a grinder, attention should be paid to the presence of a protective casing. When processing metal, this is a particularly important point. In addition, you should purchase an abrasive circle, which is intended directly for cutting metal. If it is decided to use the circle on the stone, then there is a chance to spoil not only the pipe, but also the tool itself.

Gas -flame cutting

With the help of gas -flame cutting, you can significantly increase productivity and quality of work, especially if a hacksaw machine was previously used. Semi -automatic cutting is the highest quality, and during manual cutting you can encounter a number of difficulties. Despite this, the work often is to consolidate the pipe and activate the cutting mode. It must also be noted that at the site of the pipe cut will always be an almost perfectly flat edge.

Pipe cutting using laser equipment

Recently, machine -building enterprises have been producing more and more automated laser installations that perfectly cut any metal structures. Of course, the main feature of such installations is the presence of a CNC system, which allows you to cut a cutting through a personal computer using special programs.

Definitely, this is the most practical and progressive way of cutting metal, however, there are some restrictions that relate to the dimensions of the pipes. Thus, the length of the pipe should not exceed 6.5 m, and the external diameter is not more than 160 mm.

Also, do not forget that laser equipment is a very expensive pleasure, so those enterprises that plan to use it can afford it, and cut not only pipes, but also other metal products.