A folding table is a convenient and practical thing that is indispensable in many situations. Salmatic tables are ideal for small apartments and houses, as they not only save a place, but easily transform into a large dining table if necessary. A folding table for a folding picnic easily fit in a car and give convenience and comfort in nature. The advantage of this furniture is also that making a folding table with your own hands is not difficult. Only drawings, materials, a set of tools and desire are needed.

Content

A little information about folding tables

There are many varieties of designs of folding tables. Depending on the functional purpose, their appearance and size vary. But one part combines all structural solutions - the height is always more made than the folding part, otherwise the table simply will not work out. The finished table is decorated with various ways that correspond to its purpose. For example, decorate or painted in any color.

They use folding tables in a variety of areas of life. They are used as shelves for remote trading, they are used on picnics, installed on cottages as a seasonal dining table under the open air, and often such furniture is also bought in apartments whose area does not allow to install a stationary dining table for a large number of people.

In accordance with the scope of application, tables differ in the type of material. For use outside the house, aluminum structures with a plastic countertop are optimally suitable. These materials are not subject to corrosion, but at the same time weigh a little, which facilitates their transportation. But in the house, such furniture will not look very appropriate. It is better to opt for a countertop from a natural tree, plywood or laminated fiberboard, with a wooden frame.

The tables also differ in the shape of the countertop - a rectangle, circle, oval or square. Most often there are tables with countertops in the form of a rectangle, since this form is most universal and convenient to use and store a table. For the manufacture of tables of tables, wood, aluminum or steel are used. If the legs of the table are located in parallel, then this design has less stiffness, but sitting at the table will not be very convenient. Crossed legs make the table as stable as possible.

The legs of folding tables are mounted stationary or made removable. Sometimes they are equipped with a thread to regulate the height, it is very convenient for street folding tables, as it makes it possible to adjust the horizontal level of the countertop. When planning to make a folding table with your own hands, drawings must be studied carefully and choosing the structure not only by the size of the countertop and design, but also on the features of the frame, in particular, by the alleged location of the legs.

If you need a kitchen folding table, then the ideal material for it is wood or laminated fiberboard, and the design of the frame is parallel to each other. The table from such a material will last a long time in the house, provided that it will not be laid out too often. These materials allow you to create particularly beautiful furniture, which is precisely because they are recommended as the basis for the home interior. But as a table for a picnic or summer cottage, a table made of varnished plywood is optimally suitable. It is not captured by moisture and does not deteriorate when used in open space. The legs in this case should be a cross on the cross so that the table is easily folded and does not break from frequent use.

DIY picnic table

Rest outside the city will become even more pleasant and more comfortable if you do not sit on raw land, but it is convenient to sit at a small folding table for a picnic. It also applies to fishing trips and any trips outside the city. Such furniture is made is quite simple. First you need to view the drawings to better study the design according to which the table will be made. Photos of the structure and the necessary elements are located below. The dimensions in the drawings, if desired, change to any others that are necessary, taking into account all the proportions.

The design of the table is quite simple and does not require complex manipulations and a large amount of accessories. The manufacturing algorithm looks like this:

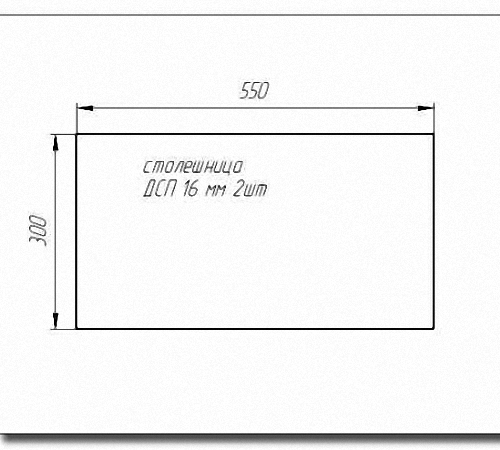

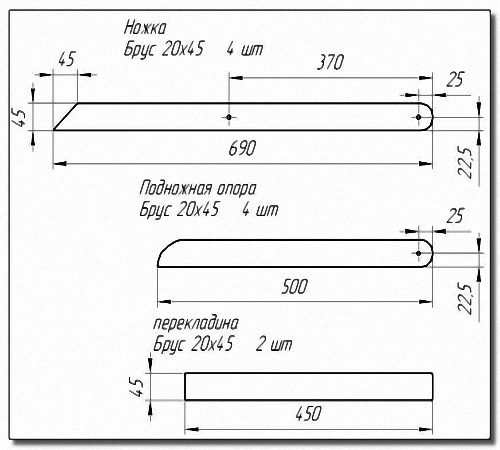

- All the necessary bars are cut on a circular saw. Their dimensions and quantity are indicated in the photo with drawings. If there is no circular saw, it is replaced by a regular or any other convenient tool.

- The countertop from any convenient material is made - varnished plywood or wood. The countertop is covered with several layers of varnish, since it is this element of the table that takes on the main moisture blow when it is on the street. In addition, such a countertop is easier to wash from various spots.

- Return to prepared bars. All saws on them need to be covered with an incriminating ribbon. The jigsaw is blocked by bars for the legs and steps. In the presence of a grinder from these elements, a right angle is cut off and then smoothed out by a machine.

- When all the details are ready, the process of their fastening begins with each other. To begin with, connect the legs and supports to each other. Then, marking for fasteners is applied to the countertop. The installation of parts is carried out using wood screws with a diameter of not more than 35 mm.

- All the details of the table are numbered, disassemble, polished their irregularities and treat them with varnish. Now the table is collected completely.

This design involves a whole countertop. This is very convenient in operation, since the smaller in the table of moving parts, the less likely that over time it will lose its stability. But when transformed, such a table changes in size only due to the folding of the legs, which makes it not very compact. For transportation in a car with a small trunk, a design with a countertop divided into two parts is better suited. This table is also made quite simple:

- A countertop is made, for this two pieces of plywood of the same size are used. Dimensions 340x500 mm.

- Make 4 legs from bars with a section of 40x20 mm. In each leg, two holes with a size of 6 mm are drilled, select the bolt heads for deepening. Planting for bolts is selected so that they come in from the outside of the table.

- Make 4 crossbars 500 mm long for the main frame. This part will be located on the countertop and serve as the main rib of the stiffness of the table. The holes in the crossbars are drilled according to the same rules as for the legs.

- Make 2 crossbars for legs, length 380 mm.

- All details are collected, focusing on the drawing.

Another convenient and compact version of the picnic table is a chartan table. In this case, the legs and countertops are not just folding, and the table is going to a real suitcase with a handle, which is convenient to transport even by public transport. For the manufacture of such a table you will need:

- 2 sheets of plywood dimensions 50x60 cm;

- 4 beams in size 44 cm;

- 2 beams in size 60 cm;

- 4 beams 52 cm;

- self -tapping screws - about 30 pcs;

- nails - about 50 pcs;

- handle for a suitcase or door handle;

- 2 loops in size 60 mm;

- 2 suitcase latches;

- furniture screws for attaching the legs.

Table assembly algorithm:

- To begin with, the frame is assembled. 2 frames of the same sizes are made - 50x60 cm, they are fastened with self -tapping screws. The finished frame looks like a small low box.

- The loops are attached to the frames with self -tapping screws in such a way as to connect both boxes with each other.

- At the same distance, 4 holes for the legs are marked, they should be 1 mm larger than the diameter of the purchased furniture screws. Next, places for holes on the legs are marked and immediately drilled.

- Now the legs are screwed to the frame and the stability and symmetry of the entire structure is checked.

- A handle and latches are screwed from the end of the frame, the table is ready. To make out the table of such a design, it is necessary to unscrew the legs, put them in a frame and close it like a suitcase.

Table processing of any of the designs described above is carried out the same way - it is treated with stain, varnish or paint. This will not only improve the appearance, but also extend the life. The product will also give the beauty a slightly different structure of the countertop. Above the algorithm for manufacturing a table with a countertop from a solid piece of wood or plywood was described, but if you make it from the racks stuffed through a certain gap, then such a table will look much more interesting.

The folding mechanism in a chimodan table is modernized using stabilizers on which the legs are fastened. The whole structure is interconnected, the legs are located so that they easily go beyond the inner edge of the frame. Now the design is assembled without unscrewing individual elements.

DIY lunch table

It is easy to make not only a picnic table, but also a beautiful functional home furniture, such as a dining table. The manufacturing process is nothing complicated. The most expensive in time and forces will be the manufacture of all parts, but the table itself is assembled easily and simply. It is only necessary to have a drawing at hand.

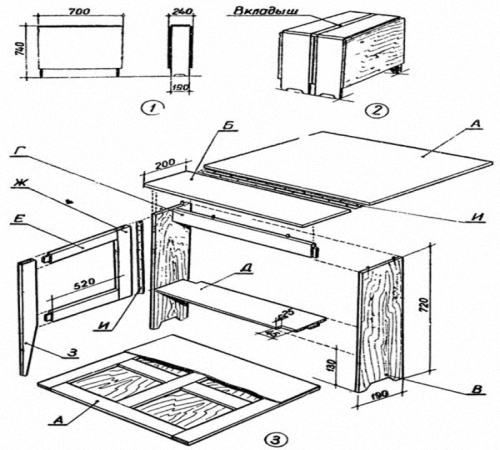

- A - countertop, part size - 700x670x20 mm. It is necessary to make 2 pcs., The recommended material is hollow shields.

- B - table cover, part size - 700x200x20 mm. It is necessary to make 1 pc., The recommended material - carpentry plates.

- B - the leg of the table, size - 720x190x20 mm. It is necessary to make 2 pcs.

- G - TsAGA, size - 638x190x20 mm. It is necessary to make 1 pc.

- D - subm, size - 628x190x20 mm. It is necessary to make 1 pc.

- E - horizontal timber, size - 500x40x25 mm. It is necessary to make 4 pcs.

- F - vertical frames, size - 500x40x25 mm. It is necessary to make 2 pcs.

- H - mobile leg, size - 720x40x25 mm. It is necessary to make 2 pcs.

- And - a piano loop, it is necessary 4 pcs.

Table manufacturing algorithm:

- First, all the cuts on the details must be treated with an edge.

- The assembly begins with the fastening of the central part with the movable leg, the bars of the vertical and horizontal location. In the diagram, these parts are indicated by the letters Z, Z and E. The mount is carried out using deaf straight spikes.

- The countertops are assembled, for this, the leg, the king and the ground are attached to it. In the diagram, these details are indicated by letters B, G and D.

- Round inserted spikes are attached to the ends of the legs a lid (b).

- The design of a movable leg and frame is equipped at the end with an elastic band or a metal button, and then piano loops are attached to it.

- The assembly of the table is completed, now it only needs to be covered with varnish or other remedy for your choice.

How to choose a folding table

The main parameter when choosing a folding table is its alleged functional purpose. Tables are large and small, equipped with or without folding chairs. If you plan to use a table for a large number of people or install it as stationary street furniture for the summer season in the country, then it is better to opt for tables with aluminum counterattacks and a steel frame. Such a table will withstand a significant load and place a large number of people. Often such designs are equipped with a cover, which will become a convenient help for safe storage of the table.

If the table is rarely used for a small company, then a medium -sized model of wood or aluminum is suitable. For street use, it is best to opt for the second option. In the design of the folding table, one of the most important factors is its small weight and size. Since the folding table is most often used for trips, it needs to easily fit in the trunk of a car.

Most often, the material used for the manufacture of tables is wood, steel or aluminum. Each of them has pros and cons. Aluminum weighs a little and is not subjected to corrosion, but in itself it is very soft and short -lived. Steel is hard and reliable, but afraid of moisture. The tree requires care and protection against external influences, while its weight is greater than that of aluminum.