Recently, among popular flooring for decoration of residential premises, laminate is the leader. This material is characterized by ease of installation, because you do not need to purchase an additional tool and invite masters, you can handle all the work yourself. To lay the laminate, only a coating and a special substrate is required. Why is it needed and which substrate to purchase, let's learn in more detail.

Content

What is the substrate for?

This finishing material has an important task - to smooth out a slight curvature of the sexes. If the floors are uneven and the differences are too large, then before starting to lay the laminate, it is necessary to pour the surface with a self -leveling mixture. After the screed is completely dry, you can proceed to the most interesting process - laying the laminate. But first you need to put a substrate, this is a kind of depreciation so that the board does not contact with a solid surface and does not deteriorate.

If the irregularity of the concrete floor is about a few millimeters, then laying the cork substrate under the laminate is allowed. Regardless of the quality of the material, its main function is the depreciation of the surface, so that as a result of the operation of the laminate, goals are not formed on the floor and there is no rigid coating load. If you ignore the rule and lay the laminate without a substrate, then stepping on such a coating, you will always hear a strong creak or crack. Here is another answer to the question of what a substrate is for - to improve the soundproofing of the room and save heat in the house.

Types of the substrate

If you decide to put a laminate in the room yourself, then you need to find out all the nuances in more detail, but you need to start with the choice of coating and substrate.

On sale you will find several options for this finishing material:

- the polyethylene foam substrate - it retains heat well, repels moisture, resistant to damage by rodents and insects, the cost is low. Of the shortcomings of this material, quick wear should be noted. After a few years of operation, the substrate is quickly sagging in high passage sites;

- the foil substrate is a foamed material with a coating on one side with a metal foil. It is used in cold rooms to enhance thermal insulation. Suitable for the equipment of the "warm floor" system. The material is expensive, so using such a substrate without connecting warm floors is inappropriate;

- the “Tuplex” substrate has an original design, a kind of puff pie, consisting of a cork, on both sides, dressed in sheets of granular polystyrene. Such a substrate is distinguished by a high degree of wear resistance, retains heat in the room, repels moisture;

- croofing substrate under the laminate. The price of the product is kept at a high level, but if you study all the characteristics of this building material, then you will not have to regret the purchase. In short, we describe the technological process of manufacturing a cork substrate. The main raw material is a cork oak bark, the material is crushed, and then gets into the press car, where, under the pressure of the fibers of the natural material, a homogeneous canvas is connected. In the manufacturing process, additives are not used, only natural material is used, and gluing the cork occurs due to the fact that in the cork tree there is its own glue - Suberin. Under the influence of high temperature, it softens and glues. The material is absolutely safe, not toxic. You can buy a cork substrate for a laminate at any construction supermarket.

Pay attention to the dimensions. The substrate is sold mainly in rolls of 5 or 10 m. The thickness of the material can also be different, from 2 to 4 mm.

Does the thickness thickness matter?

Most newcomers believe that crooked floors can be easily fixed if you buy a thick substrate. But the thickness of the cork substrate for the laminate will not solve the main problem. If the differences are large, then you will have to make a screed. If you decide to avoid such a troublesome lesson, then a small curvature of the floor can be tried to fix with a cork substrate under a laminate with a thickness of 4 mm. But here you need to take into account one important factor, if you choose the thickness of the material incorrectly, then as a result of the maximum load on the floor (areas of high patency), recesses are formed after a few months, and this will entail the rapid wear of the flooring of the flooring. Therefore, when choosing the thickness of the base for the laminate, it is necessary to take into account a small curvature of the floors - a cork substrate for the laminate should be 3 mm thick. If the surface is almost flat, then you can purchase a cork substrate under a laminate with a thickness of 2 mm.

Advantages and disadvantages of finishing material

The main advantage of the cork substrate is in universality. This building material can be used to decorate walls and even ceilings. The cork substrate will last a long time and will not be worn out even after 5-7 years of operation. By the way, the manufacturer gives a guarantee for a cork substrate for 200 years! Imagine how much the floors can last, and with them a substrate! It is clear that the laminate will not withstand such a long operation and after 10 years it will be necessary to change the old coating to a new one. But the cork base can be left, because it will remain well. This is a good savings in funds.

Pluses of cork substrate:

- ecological material, does not emit harmful substances and toxins;

- can be used in any room, even in the nursery;

- the material is not deformed;

- saves heat and has soundproofing properties.

Of the minuses, only the only drawback can be distinguished - this is a high cost.

Based on the foregoing, we can draw the following conclusion: if you are not going to change the laminate after 5-7 years, but give preference to a quality and durable coating, then you can lay a cork substrate under the laminate.

We will get acquainted with the technical characteristics of the material:

- the density of the product can range from 220 to 260 kg/1m 3;

- plug humidity is only 7%;

- high thermal conductivity - at 1m 3043 W;

- high resistance to fire. Despite the fact that the cork of natural origin, this material does not burn, and if it lights up, toxins do not release during burning;

- high strength of the material (2kg/1m 2).

How to properly lay a cork substrate under the laminate

The quality of work and the final result directly depend on the correctness of your actions and a clear sequence.

How to lay a cork substrate under the laminate

- First you need to prepare the entire area. That is, if the floor is uneven, then using a self -leveling mixture or liquid putty, you need to level the entire surface.

- After the curvature of the floors is fixed, it is necessary to walk on the surface of the grout of the skin to clean and smooth out all small irregularities and cracks.

- We treat the floor with a primer (it is better to buy a liquid with protection against mold and fungus).

- After applying the primer, you need to wait 24 hours (or a little less, study the instructions).

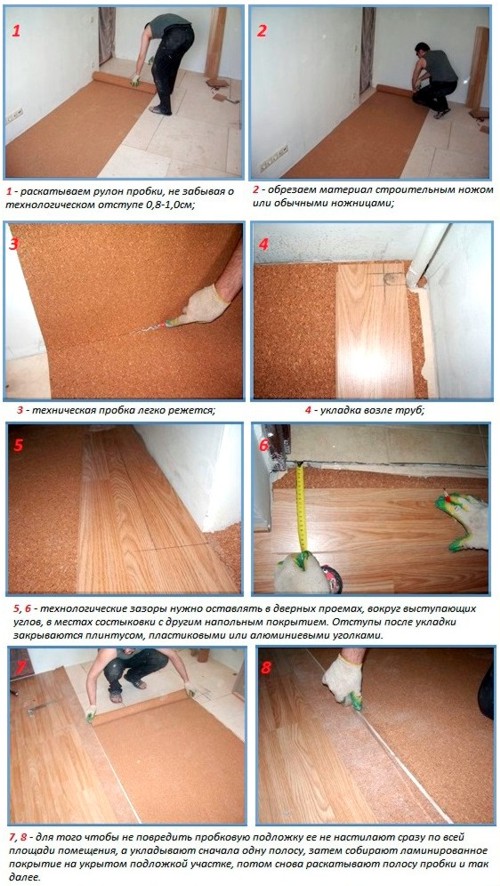

- Remove the packaging from the substrate and put it on the floor. Leave for a day to “get acquainted” with the climate of the room.

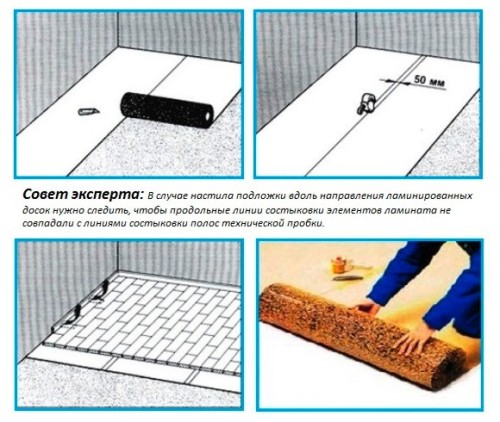

- We proceed to work: first you need to lay a layer of waterproofing. It can be a special material or dense polyethylene. We cut it into strips plus a supply of several centimeters and lay it on the floor with a small gap so that the edges of the film “climb” on the wall (up to 1-1.5 cm is enough).

- Using a construction tape, we fasten polyethylene together. Attention, in no case do not use metal brackets or nails to fasten the film, since moisture can seep through the holes, and this is the time and means for materials.

- We lay out the substrate so that the distance from the wall is approximately 1 cm. We lay each sheet tightly to each other, without overlap, the joint in the joint.

- We connect cork sheets using construction tape.

- If you want to additionally protect the coating from moisture, then you can treat the cork substrate with a special tool that repels water and any liquids.

- Everything, you can start laying the laminate.

Small secrets that will help you quickly cope with the task and extend the life of the flooring:

- any substrate needs to be laid only across the laminate to avoid displacement of the coating during operation. You need to determine in advance to the direction of laying the flooring;

- do not be too lazy to carefully clean the concrete floor of pollution. If there are cracks, then they need to be filled with a solution and cleaned all irregularities;

- the concrete floor must be treated with an antifungal mixture and wait for it to be completely absorbed;

- cut the cork substrate so that it is convenient for you to work and lay the sheets on the base, the width of the base can be different;

- remember that it is prohibited to lay a cork substrate in several layers;

- a cork wood substrate is best used for living rooms and corridors. For rooms with high humidity (kitchen, toilet, bathroom), buy tiles or if you decide to put a laminate in these rooms, then it is best to use a cork substrate with an additional layer that protects the coating from moisture for work. Pay attention to the bitumen base for the laminate in combination with a cork tree. The basis of such material is a pressed cardboard, on which a thin layer of bitumen - durable material is applied on the one hand. The second side is a traffic jam. Such a substrate protects the coating from moisture and even repels it out. Laying of combined material must be put with a cork to the concrete base. Joints are fixed with sticking paper;

- it is worth paying attention to when buying a laminate to laminate on rolls made of cork wood in combination with synthetic rubber. The material is cheaper, the quality remains on top, the wear resistance is high.

Croofing substrate under the laminate. Video: