The annexation of the balcony in a private house expands the living area and can make the architecture of the building more interesting and attractive. The balcony, a rather complicated engineering design, its extension requires compliance with the norms that ensure the safety of the structure, compliance with fire safety requirements, etc. Any protruding architectural structures on beams or console slabs are being built taking into account the rules of the sopromat.

Content

When choosing a place for the balcony, compliance with the overall architectural composition and constructive expediency is taken into account. An important panorama, which opens from the balcony, shade or solar lighting of the place. In the process of planning an extension of the balcony to the house, the internal location of the rooms and the convenience of access to the balcony are taken into account. For an extension of the balcony on the ground floor, special calculations are not required. Brick support columns or a light strip foundation on which the floor is set up and the fencing is settled.

Regulatory requirements for balconies

When calculating an extension of the balcony on the second floor, many factors are taken into account: the thickness, material and age of the walls, calculated loads, taking into account the weight of the design itself, present on the balcony of people, snow, etc. The size of the balcony, materials and the method of installing the frame depend on this.

- the calculated load on the stove along the entire plane is 200 kg/m2, the strip load is calculated taking into account the group of people standing along the parapet in the area 80 cm wide and is 400 kg/m2;

- the height of the balcony fence of at least 105 cm at a load on the handrail of the railing 30 kg/m 2, and vertical for the fence of 100 kg/m2;

- the angle of inclination of the balcony plate from the capital wall to the edge is 2 °, for the divert of the rain water (about 2 cm per 100 cm of the site).

In addition to the above parameters, 100% of the strength supply is added to the calculated numbers. Given the availability of several more specific nuances, the design of the output of the balcony is easier to entrust a competent specialist.

Balcony frames for private houses

The balcony consists of three main elements: base, protective fence and a canopy. By type of attachment of the base, balconies are divided into two types. Consillum and console-beam.

Cantileum

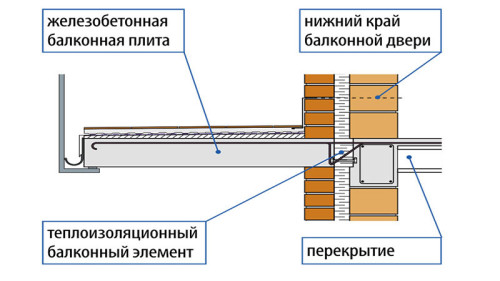

In the process of erecting a box of a house, in a bearing wall is laid at least 40 cm by a reinforced concrete slab. The following rows of building material securely fix the balcony plate. Such designs are used in buildings with thick and heavy walls. The width of the balcony site should not exceed 1 meter.

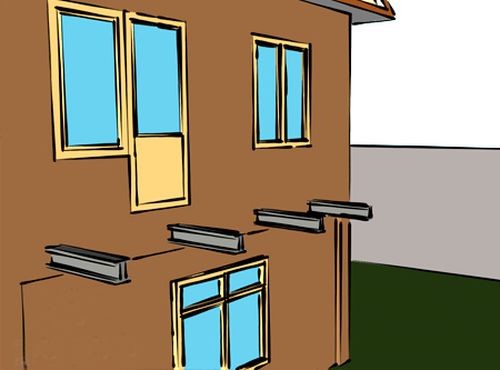

Console beams

Reinforced concrete or steel beams are laid in the wall during the construction of the box of the house. Sometimes holes are stroked in the already erected wall and beams are started to a depth of at least 40 cm in them. In this case, the balcony platform is additionally strengthened with brackets or support racks. The width of the site is allowed from 1.2 m to 1.5 meters. The support racks under the balcony allow you to increase the width of the site by 2 - 2.5 meters.

- Reinforced concrete slabs for the base of the balcony have a large weight and are installed at the time of construction. To arrange the balcony to the house, it is wiser to apply the console-beam method with the institution in the wall of the metal channel and the flooring of the wooden floor.

- A fence for a balcony is made of wood or metal. Various original variants of wooden railings or metal grilles can be purchased in a store or ordered in a workshop. In any case, the fence should be strong to have a reliable mount and be sufficient height. The canopy performs utilitarian functions of protection against wind, sun and precipitation. For it, a metal frame is made and covered with roofing material. But, if you approach the process creatively, the canopy will become a decoration of the balcony.

The device for the balcony in the house

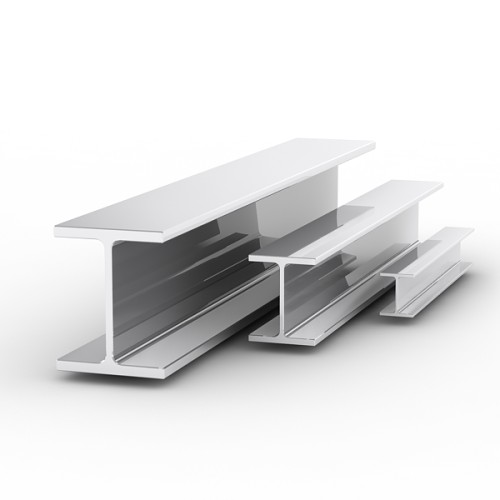

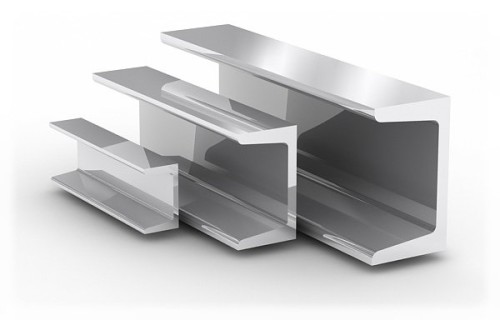

To install the base of the balcony, a channel or a breakfast beam is used. The channel has a figurative profile, and the rally beam resembles a railway rail. For a 1.5x2 meter balcony site, you will need 4 such metal beams of 2 meter length. A channel in a section of 50x150x50 or double -tank 150x50x150 with a wall thickness of at least 5 mm, provided that the wooden floor is flooring.

- In the wall, 4 holes to a depth of 50 cm with a span of 50 cm are spoken at the same level of 4. Balks are started in the holes, if it is a channel, then the wide side is aligned in levels, frightened and concrete. Under the beams to the wall of the house, a 70x70 metal corner is attached to the anchors and is grabbed to the beams of welding. This will not allow separate beams to sag in the wall of the house. The same binding is made on the ends of the balcony beams. Three metal strips are welded across the ligament beams, along the entire balcony site.

- For the reliability of the design under the extreme beams of the frame, struts are mounted. They are welded separately from the corner in the form of a rectangular triangle. The free space of the triangle is filled for beauty with an openwork ornament of a metal rod or square. When releasing a balcony beam of 1.5 meters, the side adjacent to the wall and the side of the braid welded to the beam is equal to one meter.

The support racks are mounted from metal pipes with a diameter of at least 2 inches. The upper end of the support is started under the cut of the extreme beams and fixed with welding. The lower part of the support rack, treated with anti -corrosion mastic, is immersed in a pre -dug hole to a depth of 0.5 meters. The free space around the support is compacted and poured with concrete.

Flooring, fences and a canopy of the balcony

- The floor for the balcony is arranged from a dry string board of 30 - 40 mm thick. Boards are laid from wall to the edge of the balcony. The final sides of the boards are attached to the extreme beams on the bolts, the intermediate mount can be made with self -tapping screws. A minimum gap of 1-2 mm is left between the boards. Without a gap in raw weather, it is possible to swell the boards and swelling the floor. The floor is covered with an antiseptic and paints.

- For fencing the balcony, two metal racks are welded at the corner outlets. A metal inch pipe at least 105 cm high is quite suitable. From a metal corner or pipe, a figurative profile of the railing is bent. For the calculated balcony, its dimensions will be 1.5x2x1.5 meters. At the corner points, the railing is welded to the racks, and the end ends are securely fixed in the wall. Metal mortgages are made in the wall, to which the ends of the railing are welded.

- The facade and lateral openings of the balcony fences are closed with decorative metal lattices, wooden balusters, plastic panels, etc.

- For a canopy in the workshop, a frame is ordered. The roof of the canopy can be made of galvanized iron, maclone, flexible tiles or other roofing material. The roof of the canopy on bolts and screws is attached. The canopy is installed with a mount to the wall for 4 anchors (F16, L \u003d 250mm, R cm \u003d 30 kg/cm 2) It is enough.