Brick is the most popular building material in the field of the construction of residential and industrial buildings. There are many varieties of brick, different in physical parameters, on which their area of \u200b\u200bapplication also depends. In this review, we will talk about Shamotnoy brick. But, let's start from the beginning.

Content

- Varieties of brick

- Types of chamotte

- Visual differences in the chamotum brick

- What shape can there be a shamic brick?

- The advantages of chamotis brick

- The disadvantages of chamotis brick

- The weight and dimensions of chamotis brick

- Signs of refractory bricks of good quality

- Signs of underwear bricks

- Where is it advisable to use such a brick?

- Features of masonry

Varieties of brick

- Ceramic brick (the main component is clay).

- Brick silicate (sand+clay+different additives).

- Brick refractory (sand+clay+additives that improve the ability to resist high temperatures):

- zhelsky;

- refractory;

- borovichi;

- novomoskovsky;

- throat;

- shamotnaya.

Shamot (clay) brick is made of special chamotis powder and various clays, burning blanks in special furnaces at a very high temperature.

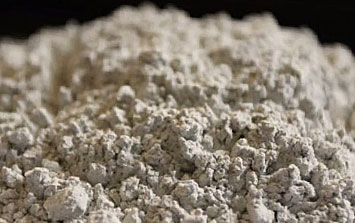

Shadow - refractory clay that has lost chemically tied water and plasticity in the process of firing, spinning to a certain extent. This raw material is produced in mine furnaces by firing at 1300-1500 ° C.

Types of chamotte

- Highly burned (moisture absorption 2-10%).

- Low -burned (moisture absorption up to 25%).

Visual differences in the chamotum brick

- Yellow (sand) shade. A rich and dark color indicates that this brick is suitable for laying the furnace.

- Grain texture.

- The rough surface.

- Special marking ("Sh").

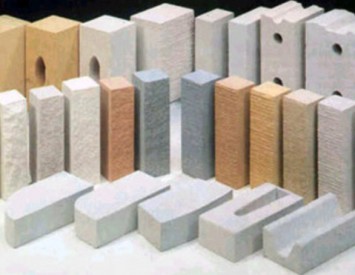

What shape can there be a shamic brick?

- rectangular;

- wedge;

- trapezoidal, etc.

The advantages of chamotis brick

- Refractory properties. Shamot blocks are able to withstand up to 1600 ° C.

- The plane, composed of this material, warms up quickly and holds heat longer than a similar ceramic (i.e., less fuel is necessary to achieve the same effect).

- Simplicity of laying. Each of the 6 sides of the sham brick can act as the front side. For comparison, ceramic brick has only 3 such faces that differ from others visually.

- He does not distinguish harmful fumes when heated, unlike other varieties of refractory bricks.

- Resistance to aggressive alkaline and acidic media.

The disadvantages of chamotis brick

- A fewer freezing-freezing that such a brick is able to take out compared to a ceramic analogue. To eliminate this drawback, you can apply a special varnish or liquid glass.

- Due to special hardening, it is poorly cut. The trim of this material can only be done with a grinder equipped with a diamond disk.

The weight and dimensions of chamotis brick

- Weight \u003d 3 kg.

- The dimensions of the most running types of this type of brick: 25x12x6.5cm and 23x11.4x 6.5cm.

Signs of refractory bricks of good quality

- The correct shape and evenness of the surface.

- The absence of chips, white divorces, cracks, bumps.

- Color saturation (the darker, the better).

- When tapping, the brick produces a sonorous sound.

- With a strong blow, it does not crumble, but is divided into large pieces.

Signs of underwear bricks

- a pale non -pronounced color.

- when tapping, it forms a dull sound.

- fragility (painted with a chisel when hit).

- too porous structure.

With excessive firing, the brick becomes black, charred and melted until the middle. The resulting product is called iron. It is very resistant to the influence of various third -party factors. It is advisable to choose it for laying foundations and sewer lines. But, for the construction of furnaces, this brick will no longer suit.

Where is it advisable to use such a brick?

- The decoration of those surfaces of street furnaces, which account for direct contact with fire - fuel, chimney, etc.

- The laying of a fireplace or furnace arranged in the house is entirely from chamotis brick.

- Creation of production plants for enrichment, metallurgical and chemical, etc. industries, such as domain furnaces, boilers and fuel chambers, etc.

This building material is often preferred when erecting a stove or fireplace, but here we must remember that the price of chamotis brick is much higher than the classic ceramic.

Features of masonry

- Masonry is carried out without prior soaking blocks.

- We need pre -cleaning the surface from clogging with a brush.

- The width of the joints during laying should be no more than 3 mm.

Preparation of a clutch solution for chamotis masonry

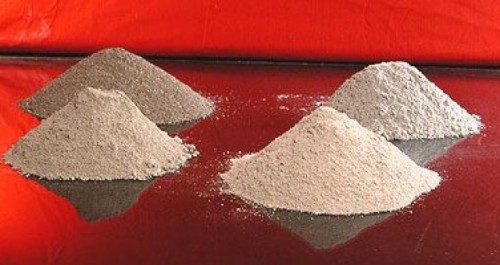

Preparing for the beginning of the masonry, you can buy the finished powder (chamotum measurement) for the manufacture of a binder solution, or you can make such a powder yourself by mixing refractory clay and chamotis sand. Consider both options.

Preparation of a solution from a mudtel (based on 100 pcs. Bricks)

What do you need?

- 40 kg of finished powder (output - 3 buckets of finished substance);

- pure water (without additives, not salty);

- portland cement - 6kg (15% of the weight of dry measure);

- electric drill (concrete mixer).

Preparation technology

- In dry refractory powder, just add water. This must be done before the time when the solution becomes cream -shaped density.

- At the same time, interfere with the solution no less than 5 minutes using a mixer, electric drill or concrete mixer (with large volumes).

- Leave the resulting substance for an hour.

- Mix again.

- Add Portland cement to improve strength qualities.

- The solution is ready for use.

The use of mercnes is certainly a more comfortable and simple option. However, a solution made of the main components with your own hand does not give such a strong shrinkage and has the best strength characteristics. Therefore, it is better not to be lazy and prepare the solution yourself.

DIY solution made of ball sand and refractory clay

What do you need?

- 1 packaging of ground clay (preferably white kaolin);

- shamotnaya sand (chopped battle of chamotis blocks);

- water (clean, without additives, not salty);

- sieve (with cells of 3x3mm).

Creation technology

- Soak the clay so that the water covers it completely.

- Leave for a while (from 12 hours to 2-3 days).

- Stir the substance periodically.

- Wipe the clay thoroughly through a sieve.

- Add the sand sieves through a sieve (its mass should be twice the mass of clay).

- Mix thoroughly.

- Start the masonry.

Important!

- If white kaolin clay is not found, replace it with Cambrian blue.

- Pure clay almost does not smell. If there is a very strong smell, then organic additives did not wash out of clay.

- The only permissible replacement of chamotis sand is mountain sand without inclusions. Do not try to replace it with a quartz analogue, marble or granite chips.

- The final solution should be such a density that it is free to crawl from the trowel without sticking and without smoking it. It should be without lumps and clots.

A solution made according to all the rules does not need to use additional additives. However, if there are doubts regarding the quality of the mixture, you can use certain substances to improve some qualities.

Additives

- To enhance strength qualities: cook salt-100-150 g/bucket; Cement 150 - 1/2 trowel/bucket. But, it should be understood that by adding cement, you will no longer be able to repair the masonry, and salt often leaves whitish stains.

- To enhance plasticity-liquid glass (1-3% of the volume of the solution).

The ball brick today has become indispensable, its use guarantees the preservation of masonry in specific operating conditions, increases fire safety and gives a special visual effect to home stoves and fireplaces.