By the location and specifics of the installation of lamps, it is customary to divide the ceilings made of drywall into structures with outstretched lighting and hidden backlight. In the ceilings, which belong to the first type, the lighting is suspended or built using specially prepared holes. It is worth saying that the frame and the skin of the ceiling made of drywall have a low bearing capacity. Therefore, if this installation method is used, then the selected suspended lamps should not weigh more than ten kilograms.

Content

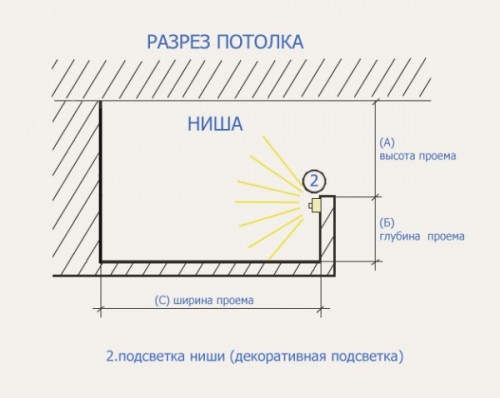

As for the second type of ceilings, in this case, the lighting is located in specially made niches for this, which are located between two levels of drywall sheets. In this case, light in the room will fall by reflection from the surface. With the help of hidden backlighting the ceiling made of drywall, with the right approach, you can create a unique cozy atmosphere. We will talk about the installation of such designs in this article.

The choice of backlight

If you want to erect a gypsum plating ceiling with backlight, then, first of all, you should think about choosing the most suitable lamps for use as a backlight. In most cases, the choice falls on fluorescent and LED lamps. Here we will talk about LED lamps.

The backlight with such lamps has a number of obvious advantages:

- First of all, this is their energy efficiency, which is almost one and a half times higher than other lighting options.

- Diode backlighting of a drywall ceiling made of LED lamps is an economical and very practical option for any home. At the same time, such lamps make it possible to provide a sufficient level of lighting in the room.

- Such lamps are usually installed using a self -adhesive tape. Therefore, the simplicity of installation is also their undoubted plus.

Today, there are control units that allow you to control the light of the ceiling from drywall at a distance. The photo below this clearly shows.

To date, there are several different options for LED lamps on sale. Each of them has a set of parameters:

- One of these characteristics is the type of LED. For lighting the room, models such as SMD-3528 and SMD-5050 are most often used. The latter is more powerful.

- A rather important parameter for decorating the room is the color of the LED lamp on the tape. Most often, one-color ribbons are used, but there are also RGB tapes that can change colors. If for lighting you want to install just such structures, then you need to buy special controllers that provide sufficient brightness of the glow.

- Another significant characteristic of LEDs is the density of diodes. By this, it is customary to understand the number of light elements located on one meter of tape. For lighting, ribbons with different density are used, for example, structures with a density of 30, 60 and 120 are actively used. Moreover, if the first two are suitable for contour backlight, then the third is not used for this.

- An equally important parameter of any LED lamp is their protection against moisture. It is provided due to special silicone insulation.

Stages of carrying out work on the installation of illumination of drywall ceiling

- You need to start installing the ceiling with backlighting with its marking.

- Next, you need to assemble the frame. For the frame, the same metal profile is most often used, which is used for any suspended ceiling made of drywall. To make the frame you need to perform the following actions:

- first, you need to make an indentation about 100 millimeters from the ceiling overlap and draw an axial line at this distance in the camps of the premises. This line will pass throughout the perimeter and determine the level of the future ceiling. To check the line, we use the building level;

- then the start profile should be fixed along the line;

- now you need to fix the suspensions, and it is necessary to attach the frame from the main profile;

- the frame is reliably fastened with the help of ordinary screws and special combat connectors;

- line with drywall sheets.

How to install a box of boxes with a niche for backlighting

Drywall cannot be considered a strong material. Therefore, if you do not use other structural elements, then it will not be able to withstand the severity of the second tier. It is in it that the backlight is usually mounted.

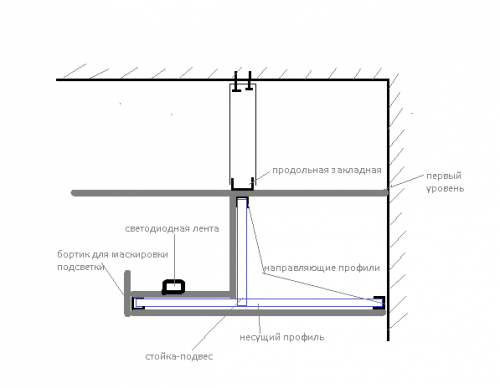

For this reason, the frame of the second tier of the ceiling is usually attached through the drywall to the upper level guides. In order to achieve this, such mounts must be placed in the same place where the guide will take place in the future, which forms a box with backlight. Two guides, which go across the longitudinal profiles of the main ceiling, are usually attached without problems at a distance of 400 millimeters from each other. The situation is different with the process of fastening the other two guides, especially if there is no longitudinal profile above them. Such designs are very unstable. Therefore, you have to lay this profile specifically when the main frame is installed. Sometimes the second level should be designed, based on the existing structure.

Not a problem if the mortgage was forgotten. After all, longitudinal profiles are usually located quite close to each other, and this makes it possible to choose any of them to use it as a base.

The installation process consists of the following steps:

- Make a retreat from the main ceiling to the height of the box, which will be laid later. And at this distance, place the marks.

- After that, connect these marks with a horizontal line.

- Further around the perimeter, it is necessary to mark the marking, while retreating from the walls of the room to the desired distance. As a result, the lines connected together should make up the figure in the form of a correct rectangle. If you know that the walls in your room are perfectly even, and the corners are only straight (strictly 90 degrees), then you can make the distance from the walls not equal along the entire perimeter. Otherwise, marking should be carried out using a square.

- We move on to the process of installing a suspended structure with backlight. It is best started by fixing the guide profile according to the previously evaporated markup. The profiles fixed on the ceiling should be located with shelves down, and the structures on the walls are directed towards the parallel (opposite) wall. The guides on the ceiling must be screwed into the profile of the main frame.

- Then you should create designs of rack suspension from the ceiling profile. For this purpose, cut the material into small parts. In height, they should be equal to the size of the box. On the one hand, it is necessary to make small incisions on the bends, and then bend the back wall inside. To calculate the amount of material, be sure to keep in mind that the suspensions will need to be fixed with about 500-600 millimeters.

- Then, previously prepared racks-suspension racks, which were previously prepared, should be inserted into the guide profile. After that, fasten them with metal screws.

Next, you need to make blanks from the profile. To do this, it is cut into parts equal to the length of the lower part of the structure of the box. - It is important that their size differs from the distance between the wall and the guide profile installed on the ceiling. The fact is that on the lower plane of the box to fasten the LED lighting of the ceiling from drywall, a shelf is required. Thus, the length of the profile should be more than the specified distance, at least 50 millimeters. This should be enough to place small lamps or LED ribbons.

- Then we place the resulting blanks at one end into the guide profile located on the wall. Then fix it with self -tapping screws.

- The second end of the workpiece should be fastened at an angle of 90 degrees with a stand-suspension.

The result is a certain frame with protruding profiles. Now the parts of the material are drowned out. To do this, cut the segments of the desired length from the ceiling profile and then insert them inside. These segments will play the role of the basis for fastening drywall strips that form a shelf designed to install ceiling lighting. - Next, the protruding ends of the frame must be closed. To do this, fix the guide profile along the perimeter on these ends, and then fasten it with ordinary screws. Preparation of the frame is completed.

How to execute the frame of the frame

- It is not difficult to do the facial work of the box. The most important thing here is to cut drywall evenly and in the correct order to carry out the necessary work. The material should be cut using a hacksaw. Thanks to this, drywall ceilings with backlight will look more carefully.

- After that, you need to process the edges with a shirt and cut off the excess of paper from them.

- Before starting work on cladding, be sure to stretch all the wiring necessary in the future for backlight.

- First, it is necessary to fasten the strip to the niche shelf. If it turned out that there is too much distance between the first level and it, then screwing the screws can be performed using a corner bit.

- After that, it is necessary to clarify the vertical part of the box. For this purpose, the drywall should be attached to the suspension racks, and then to the ceiling guide. It is important that the joints of the attached stripes fall on the racks.

- Next, proceed to the cladding of the horizontal part of the box.

Then fasten the side to the end part of the structure. Thanks to this, the side will not be visible to the backlight, which in the future will be located on the niche shelf. It is important that between the upper edge of this side and the main ceiling, the distance is at least 50 millimeters. To strengthen the upper edge, before the start of work, the P-shaped profile should be put on it. - The installation of the backlight is almost completed. It remains to mount the lighting elements. This will require LED tape. Today they are offered various capacities. More tapes can be plain or change colors. A 12 volt power supply will also be required. When the type of LED tape is chosen, it is necessary to calculate the power you need. To this end, measure the perimeter of the niche, which was prepared for the installation of future backlight. Then calculate the work of this value and power of one linear meter of the tape.

Important nuances:

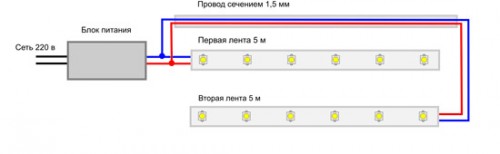

- LED ribbons cannot be connected to the power supply sequentially. Otherwise, each subsequent tape will shine not as bright as the previous one.

- In addition, you need to know that the higher the power value of the power supply, the larger it is in its dimensions. This must be taken into account in the manufacture of the side necessary to hide the backlight. As an alternative option, you can purchase your own separate power supply for each tape.

Installation and subsequent connection of LED tape

- Such tapes are usually offered in construction stores in the form of five -meter bobbins. An adhesive base is applied on the back of each of them, which allows you to install it on a surface of any orientation - both horizontal and vertical. Therefore, when working on drywall structures, in order to attach diode backlight, you can use a shelf in a niche or an internal wall-bortion.

- When connecting the tape directly to the power supply, it is important to use the right circuit.

- For the second tape, the wire must be laid in a niche parallel to the tape, which was laid first.

- The power supply should be installed in a drywall niche in the place where the wires were previously displayed. Next, it can be connected to the network. This will be the last step in the construction of the ceiling with illumination.