Most of the apartments built in the "Khrushchev" times are not particularly distinguished by their spaciousness. However, during the construction of such premises, individual and, as a rule, small rooms - pantries were always provided. In the pantries, it was customary to store all kinds of necessary and unnecessary things, clothes and conservation. This tradition has been preserved to our times, today people are equipped with dressing rooms and even workshops from the pantries, if they allow the size of the room. Compact regiments in the pantry allow you to distribute many different things on a relatively small area.

Content

Calculation of space

It is rational to use the room of the pantry by proper placement of shelves and racks in it. The process of making shelves with your own hands will not take much time and will not require additional knowledge, the main thing is a competently organized layout of the shelves in the pantry.

You can fill the pantry with different furniture and accessories. When arranging this room, shelves, various bedside tables, chests of drawers, mirrors, suspended shelves are often used.

Having organized a small closet in your apartment, it is worth deciding how to properly place the shelves in the pantry and thereby save space. Breaking the walls and expanding the room already a small apartment is not worth it, it is better to make the shelves with your own hands.

If your pantry performs the power to store conservation and all kinds of jars, then try to make the maximum amount of wide and stable shelves from high -quality wood with a metal fortification that would withstand the load.

For books and other things, you can make hinged shelves and shelves with glazing.

So that the wooden material does not rotate and does not collapse under the influence of time, in the manufacture of it, it must be covered with stain, varnish or paint.

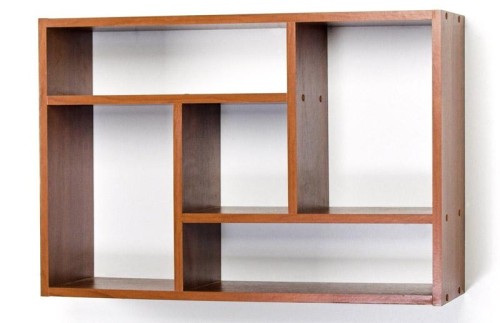

What the standard wooden shelves in the pantry look like, you can see in the photo below.

Load on the shelves

Before making shelves in the pantry, you need to decide on the proposed load on them. For storage of cans with conservation, strong and stable shelves are suitable. But, in general, the load depends on such parameters as:

- the thickness of the boards. The greater the weight of the things loaded onto the shelf, the thicker the board should be. Optimal thickness - 3 cm;

- fastening. Wooden shelves can be attached to the walls, both using metal devices and wooden bars. The highest quality is mounting on metal brackets. Plastic in this case will not work;

- the number of fasteners. The longer the shelves, the more fasteners should be.

Advantages of shelves in the pantry

It is possible to free your pantry from excess pile of cabinets and racks by placing shelves in it, since the advantages of these compact structures are obvious:

- saving the space of the pantry;

- spacious shelves allow you to hide all unnecessary things from the field of view;

- shelves in the pantry is a rejection of excess bulky furniture;

- the rational use of each meter in your apartment.

Tips for the manufacture of shelves

In order to make a shelf for the pantry correctly so that it serves for a long time, before starting manufacturing, use several important tips:

- Decide on the appointment of the future shelf. If you plan to store large boxes, bags and cans in the pantry, you will have to make the shelves spacious and deep.

- To protect the racks from destruction, the tree must be pre -treated with varnish or stain.

- If your pantry is long and narrow, then the most correct solution will be placed shelves in the form of the letter “P” on three walls.

- For the manufacture of shelves, it is better to use natural wood, and for partitions you can limit yourself to plywood sheets.

Installation of shelves in the pantry

Free square meters of your apartment can be rationally used to create a separate room. To decorate the pantry, you do not need to come up with thorough and bulky cabinets or racks, it is enough to place compact and spacious shelves in it.

If you agree with this decision, then make sure of the preparation of the walls. First, conduct an inspection of the walls for the presence of roughness. If there are irregularities, then plastered the walls. It is better to dye the surface in light colors. Since the pantry itself is a room without windows, the bright walls will remove excess gloom.

You will need: for the installation of shelves:

- wooden boards;

- drill or punch;

- screws;

- brackets;

- construction level;

- pencil;

- scurgery.

When the walls in the pantry are prepared for work, for starters with a pencil and level, make markings. It should be determined in advance how the shelves, their distance and dimensions will be located. The width of the shelves should allow them to place large items, banks and at the same time so that the shelves do not close the passage into the room. Dimensions are selected individually, depending on the parameters of the pantry.

The course of work:

- Screw the bracket to the wall. Metal brackets are more durable, since plastic may not withstand heavy loads. Determine the correct attachment of parts by level.

- Pre -cut boards suitable for the size of your pantry, fogging with sandpaper or a grinder with a grinding nozzle.

- Process the finished shelves with stain and varnish.

- When the boards are completely dry, place them on the brackets and screw them with screws. As a landmark, the approximate distance between the shelves should be 0.5 m, and the optimal depth of the shelves is 30 cm.

- When the shelves are fixed on the brackets, we can assume that everything is ready. Such convenient and durable shelves in the pantry is very simple, you do not need a large number of materials and special skills.

Shelves in a pantry of strict boards

Before starting the manufacture of shelves, stock up on the necessary tools and special metal mounts. The drill for the perforator must be selected for wood or concrete, and the thickness of the strict boards for shelves should be 20 cm.

For work, you will need:

- electric lobe;

- punch;

- plane;

- screwdriver;

- knife;

- roulette;

- pencil;

- self -tapping screws;

- pVA glue;

- sandpaper.

The length of the shelves for shelves is selected exclusively onto individual order depending on the size of your pantry. In addition to strict boards, you will also need long wood bars (4.5x4.5 cm), plywood (8 mm thick). Treat the tree with a stain and then cover with varnish.

Production technology:

- Before starting work, it is better to make a drawing of future shelves. According to this sketch on the walls on both sides, design the placement of the shelves.

- Wall the wooden bars to the walls with self -tapping screws, which will subsequently fasten the shelves with each other. Thus, you should get a frame of bars.

- To make it convenient to lay the shelves, attach transverse ones between the longitudinal bars. Determine the distance and height between them yourself.

- Next, from the clay wood with a jigsaw, cut the shelves suitable for the dimensions of your frame and put them on the transverse bars. They should be applied, as they say, “in a paw” or to each other. Fix them with PVA glue and self -tapping screws.

- Make the first and fourth shelves continuous, and two medium -sized shelves - divide with a plywood among themselves. Thus, it will turn out sections.

- The number of shelves on both sides may not be limited. Having spent a minimum of free time, you will construct the most ordinary but very durable shelves in the pantry for storing all kinds of items.

Pantry shelf

To make shelves in the pantry with your own hands, you will need boards with a thickness of 25-30 mm, bars with a cross section of 20x30 mm. If the width of the pantry allows, then a metal bracket or a pipe segment will come in handy.

For work, you will need:

- wood (pine) or finished boards;

- self -tapping screws;

- lobby;

- sandpaper;

- level;

- pencil;

- metal pipes;

- flanges.

Before starting work, make markings on the wall of the pantry. The most acceptable option for installing shelves is a step of 30 cm. In this case, banks can fit on the shelf with a volume of 3 liters and shoe boxes.

Production technology:

- Using the construction level and pencil, mark the horizontal lines, both on the side walls of the pantry and on the back.

- Pre -cut wooden bars pre -cut to the desired sizes to the walls. On the sides - bars 30 cm long (this value is the depth of the shelf). Fix each beam on 2 strong self -tapping screws under the hexagon. Fix long horizontal bars with three self -tapping screws.

- The shelves are made from the board that you need to pre -process.

- Hackle the boards cut in size with sandpaper or using a grinder with a special nozzle.

- Place the finished, emphasized and treated with a stain, put on bars and screw with self -tapping screws. To do this, you will need screws for wood 35-40 mm long.

- When the shelves are in place, it is necessary to strengthen the structure so that the shelves do not bend and do not break under the weight of the cargo. Buy a pipe for furniture and 2 flanks in advance in advance for each shelf.

- Cut the first piece of the pipe. Its size is the height from the floor to the first shelf. Insert the pipe between the shelf and the floor and attach the flanges.

- Try to do so that the vertical pipe between the shelves is on one vertical line. In this case, you can achieve maximum stability.

Hinged shelf for a pantry

This is not a complicated example of how to make a hinged shelf will help you independently decide on a set of necessary tools and the manufacturing technology of shelves in the pantry.

For work, you will need:

- wooden board 1.5x2 cm thick, width - 20 cm.;

- wood self -tapping screws or furniture conformarts;

- lobby;

- drill;

- screwdriver;

- bulgarian;

- pencil;

- ruler.

First, prepare the tree for work. Cut the board with a jigsaw along the length. You will need two boards of 80 cm and two - 25 cm each. When the boards are cut off, sand them from all sides with a grinder with a special nozzle. Align the wooden surface until it becomes perfectly smooth.

Production technology:

- When the boards are prepared, proceed to their assembly. To do this, connect all 4 boards to each other so that the box comes out. Make holes with a drill and screw the configurations.

- When the box is assembled, on the back side, screw metal hooks for furniture with screws.

- Cover the tree with a stain and then it can be painted in any color or varnished.

- When the coating dries, the finished hinged shelf can be attached to the wall.

You can see the process of manufacturing a wooden shelf in the video.