The issue of staining the floor should be paid to special attention, since this section of the building is most susceptible to various kinds of influences. Among the variety of colors, it is difficult not to get confused. Therefore, we will continue to talk about the choice of paint for various kinds of floors and how to paint the floor correctly and efficiently.

Content

Playing sexes - advantages and disadvantages

To update the appearance of the flooring, paint is used. This method is used by both apartment owners and owners of non -residential premises. The main advantage of flooring is the fact that paint is capable of applied on any kind of surface: from wood, concrete, gypsum, etc. At the same time, painting does not require hiring specialists or using special equipment. Even one person is able to fulfill it.

Among other advantages of staining the floor, you should highlight:

- the stability of the coating before moisture, since most of the colors applied to the floor have moisture resistance;

- the paint creates a protective film on the floor, which protects it from various kinds of influences;

- the coating becomes easy to care and easily withstands any type of cleaning, both dry and humid;

- the application of paint is carried out quickly and does not require special physical efforts to conduct it, in addition, after the paint dries, the floor is ready for further operation;

- this type of decoration is characterized by efficiency and affordable value, therefore it is the most popular among alternative options.

Among the shortcomings of painting floors in the house, distinguish:

- a low level of thermal insulation, in the winter walking on the painted floor does not bring comfort, so it requires the installation of rugs;

- low level of wear resistance, this coating is not able to operate for a long time and requires periodic update;

- the low speed of drying, most colors dry for two to seven days, at this time it is forbidden to walk on the floor;

- the appearance of the coating is quite simple, therefore, when arranging a special design room, flooring will be inappropriate.

How to paint the floor - process technology

The first stage of work is preparatory. It requires the removal of the old flooring or other finishing materials, if any. In the presence of fat spots on the surface, they are removed using degreasing agents, such as White Spirit.

When using wax in order to rub the floors, it should also be removed. It is better to do this using a solution of soda with water, in the proportion of a glass per seven liters of liquid. Next, apply the mixture to the floor surface and erase the wax using a hard brush. At the end, rinse the floor with clean water and leave until completely dry.

If there are convex knots on a wooden floor, remove them with a chisel, and drown the hats from fasteners for several millimeters deep into it and plunge.

Before starting staining, treat the surface with a primer or olifa, the latter option is suitable exclusively for floors made of wood. If it is possible to wait a few days until the solution is absorbed into the surface and begins to perform the intended functions. If necessary, there is a perfectly flat surface, it is recommended to treat the floor with putty, choose compounds with an oil base, it is they who differ in high wear resistance and will last for many years. Keep in mind that the color of the putty should not differ much from the color of the floor. Apply putty on the entire surface of the floor, eliminate irregularities or minor defects. With the help of the skin, go uneven areas. If desired, repeat these actions several times until the surface acquires the desired appearance.

After the preparatory stage is completed, the staining procedure follows, which will make the floor attractive in appearance and protect it from external irritants.

Before starting work, pour the paint out of the can and mix until the mixture acquires a homogeneous consistency and structure. Keep in mind that the presence of lumps or small clots is unacceptable.

Using a painting tape, protect areas that do not require staining, but directly in contact with the floor. It is this material that will protect these places from a sudden fall of paint.

Carry out staining in stages. First, apply the first layer of paint, after drying it, apply another layer. Approaching the second layer will make the surface more attractive and high -quality painted. The second layer should dry at least four days.

Tip: when re -staining to the surface, it is enough to apply one layer of paint, but if the floor is stained for the first time, then at least two, and sometimes three layers should be applied.

Keep in mind that the application layer should be thin, otherwise, after a certain time, it will be deformed and swollen.

The staining of the wooden floor is carried out horizontally by the movements of wood fibers. It is preferable to start work with the perimeter of the room, namely, from the skirting board.

Take a little paint, squeeze the brush on the edge of the tank in which the paint is located and apply it to the surface. Keep a brush under an inclination in relation to a painted surface. Try to carry out work with smooth movements - strokes. The power of the brush is affected by the required layer thickness and its color saturation.

After staining the skirting boards, proceed to apply the paint on the entire surface of the floor.

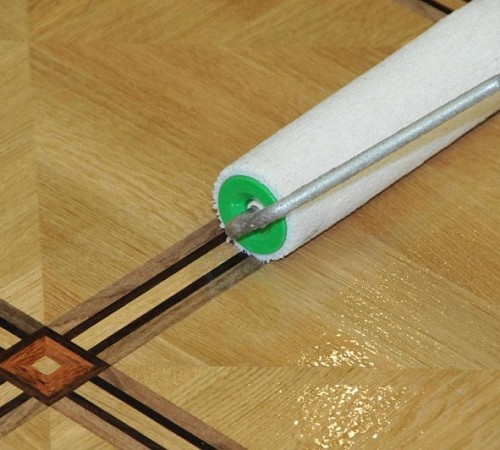

It is better to do this with a roller. Start work with corner sites:

- lower the roller into the bath with paint;

- soak it;

- squeeze the embossed area on the bath;

- attach the roller to the floor and roll the paint on the surface.

Tip: Do not tear off the roller from the floor until there is at least a little paint on it.

When the first layer of paint dries, inspect the surface for the presence of defects, and, if necessary, carry out repeated staining. The floor should not contain stains, drops from paint, stains, stones or traces of the roller.

Take care of cleaning the entire glued tape, residues of olifa, oil on the floor. This is done using periodic floor cleaning with a special solution, for the preparation of which it will be necessary to dilute water with vinegar. In this case, the addition of soap, powder, any cleaning products or soda to this mixture is unacceptable, as this will significantly affect the attractiveness of the coating. If the appearance of the floor is satisfactory, proceed to its operation.

Painting a wooden floor

Wooden floors are environmentally friendly types of coatings that are able to maintain a healthy microclimate and the atmosphere in the room, so their popularity is very great.

In addition, this type of flooring is durable, durability, stability to many stimuli. But at the same time, the wooden floor requires special care, and in particular, processing of various kinds of antiseptics, impregnations, etc.

Before starting staining a wooden floor, you should take care of choosing a quality material that will help save it during operation.

In the relationship with the appearance, paint and varnish materials for wooden floors are:

- transparent;

- color.

The first option consists of varnishes or impregnation. Some of them contain special substances that contribute to a more clear manifestation of wood texture.

Color types imply the use of colors of various origin. Among them, materials should be highlighted:

- polyurethane;

- oil;

- alkyd;

- acrylic origin.

The main functions of the impregnation are the protection of a tree from a fire or biological stimuli in the form of fungi or mold.

There are two types of impregnations:

- antipypeyte;

- biocide or antiseptic.

The first option makes the tree impregnated and protects it from fire. Their use is associated with the buildings of public, industrial or residential purposes.

The latter helps to improve the antiseptic properties of a tree and protect it from biological exposure.

There are two types of impregnations:

- surface action;

- deep action.

Only the first option is suitable for applying the floor with your own hands. Before applying the impregnation to the surface, it should first be cleaned and dried. To apply the impregnation, use a spray or brush.

Another type of impregnation is an oil basis. For their manufacture, wood or linen oil is used, as well as modified natural resins that strengthen and protect wood tinting. The oil base is better absorbed by wood, so it acts more efficiently.

Pay attention to such types of oils in which there is no solvent. It is better if the oil has a natural base and does not need to wait long for its drying. The use of oils is associated with rooms with a high operational load, such as corridors, living rooms or entrance hall. In addition, they are suitable for flooring in unheated rooms or in rooms with a high level of humidity.

If we consider the issue of choosing varnish or paint, then here we should proceed from the individual characteristics of the premises and personal preferences of its owners. Lacca is less stable before the influence of mechanical stimuli in the form of shoes, heavy objects, etc., therefore, its use as a floor covering is limited.

In the process of choosing a paint, pay attention to the environmental factor, the best option will be the material on the water-dispersion basis, which does not contain organic solvents in its composition.

This type of paints is characterized by water resistance, good clutch with the surface and stability of color. For painting the floor in the kitchen or in the bathroom, it is recommended to purchase an acrylic -based paint. It is more durable and stable before moisture. To paint the parquet, use alkyd enamel.

Tip: When choosing the number of paint, you should first find out the area of \u200b\u200bthe painted room. Each bank with paint indicates its consumption per square meter. In the calculation, it is necessary to take into account the number of layers and calculate the consumption of paint.

Do -it -yourself painting instructions:

- clean the floor, take care of the absence of dirt, dust, various kinds of spots on it;

- set and stick all the cracks, wait for their drying;

- pull out, roll and dry the floor;

- apply antiseptic compositions and wait until they dry;

- paint the floor with chosen varnish or paint.

Tip: apply a second layer of paint, only after the first dries completely. Otherwise, the paint is deformed.

The procedure for staining varnish is practically no different from applying paint. Although here there are their subtleties. After applying the first layer, you should wait for its drying, polish the surface and apply the second layer. Subject to this technology, the coating will acquire perfect evenness and pleasant shine. The varnish is applied at least three layers.

Painting the floor with paint is carried out by various technologies, among which we will highlight the three main ones:

- Coating a wooden floor with the help of olifa or primer. Drying for three days. Application of paint, drying it. Approaching the second layer and waiting from 3 to 6 days.

- Speech putty using a mixture with an oil base. Alignment of cracks and other defects. Floor processing with fine sandpaper. Its putty and alignment. Application of paint in two or three layers.

- Olifa application to the floor surface. Its drying and putty, which is carried out several times. Stripping the floor with the help of a skin, its primer, drying and painting at least three layers.

Tip: When choosing the type of primer, you should take into account the type of paint, which will be applied to the surface of the floor. For example, when applying acrylic enamel, the primer should be acrylic.

Painting of concrete floor: Features and technology

The quality of surface preparation directly affects the duration of the operation of a concrete painted coating. First of all, you should remove dirt, garbage, dust, old paint or bitumen from the floor.

Take care of the removal of concrete crumbs, lay down and plunge small surface changes, if any. Using a special grinding machine, grind the surface. It is this process that will make the surface even and significantly improve the adhesion between the paint and the floor.

The use of a vacuum cleaner or a regular mop will help get rid of dust. To blame the concrete base, acquire the compositions of polymer origin. They will significantly improve the quality of concrete. To strengthen the concrete surface, use topping - this is impregnation with a strengthening effect. Funds with strengthening action will increase the strength of the base and protect the floor from the appearance of dust by 4 years.

In order for the clutch between the concrete floor and paint to be the best, use the primer. Among the wide variety of this material, select the composition, in accordance with the type of paint that will be processed the surface.

To apply a primer, use a foam roller, which contributes to the uniform distribution of soil on the surface. Application of a primer requires compliance with a special technology:

- first you need to mix it;

- so that the floor is not slippery, add a little quartz sand to the finished mixture;

- apply the composition with two or three layers.

After the purchase and selection of paint for the floor, the type of type used in the work should be determined. It can be an ordinary brush, roller or spray gun. The decisive factor in this issue will be a paint that will be applied to the surface.

The last option contributes to the best application of paint. In addition, it is characterized by ease of execution, efficiency and a small amount of time that takes staining.

Next follows the drying of the floor, which is carried out in certain conditions. When conducting this process, the temperature in the room should be about 19 degrees, and humidity - up to 86 %. Paul dries for three or eight days, it all depends on the conditions of drying and type of paint. After drying - the coating is ready for further operation.