The cellar in the summer cottage is the most necessary object, because having grown a decent crop of vegetables and fruits, we can nullify all the results of our works if we do not provide their proper storage. How to build with your own hands this important structure is told in this article.

Content

Varieties of cellars

There are 3 main types of cellars:

- fully buried in the ground;

- dried out half;

- ground.

Where to place the cellar

The construction of the cellar in the country begins with the choice of a place. You should proceed with the following reasons:

- If you need to save space, place it under the house or under one of the outbuildings. Of course, at first we swear the cellar, and then we are already erecting the building. Such a cellar is most convenient to operate.

- When the size of the site allows you to build a separate cellar, then in addition to its direct purpose, it will also become an interesting element of landscape design. It should not be forgotten that when choosing a place, the decisive factor is hydrogeological conditions - groundwater levelFirst of all. The best place is a hill.

How to make a cellar in the country

To understand how to make a cellar in the country, first we will consider the easiest option. Such a primitive non-capital cellars sometimes do to use it to store products brought with them and some small part of the crop. The process of its construction is made up of several stages:

We make a sketch where we indicate the dimensions of the cellar, the necessary materials and the approximate cost.

- We proceed to the pile of the pit. The optimal depth is to your height.

- We arrange the bottom of the cellar, i.e. Pour a layer of crushed stone - about 15 centimeters, sand - 5 centimeters, trim and pour concrete solution. This element performs two functions - the foundation and gender.

- In the corners of the pit, even before filling the concrete mixture, put up racks from the corner. After the concrete floor freezes, tighten the frame with metal crossbars.

- To prevent the soil shedding, we put a grid with a small cell behind the frame.

- We install the lid, isolated well so that it does not pass the air from the outside.

- We arrange primitive ventilation in the form of a pipe. The simplest cellar is ready.

Capital cellar in the country with your own hands

Thinking to build a capital cellar in the country with your own hands, such that it serves any generation, come to every step. Now we consider the option of a cellar located completely underground. The main thing: start building when the street is plus temperature.

We select the material

Soberly evaluate our financial capabilities, and then decide what to choose for the construction of your grocery safe:

- brick;

- concrete slabs;

- wood;

- metal.

Choose sizes

Experts consider the following parameters optimal:

- The volume in the final form is 2x3x2 m, the length, width and height, respectively. These dimensions change depending on specific conditions and needs, but in any case, 0.5-0.6 m is added to the length and width of the pit.

- Paul-0.5-0.6 m above the lines of groundwater.

- Ceiling ceiling-0.2-0.3 m lowered below the depth of freezing of the soil.

- The thickness of the walls is 0.25 m.

Concreting the base and walls

Having chosen the sizes suitable for ourselves and the jelly torn off, we proceed to pour the bottom of the pit with concrete:

- We align the bottom of the pit, strictly controlling the horizontal level by the building level.

- We fall asleep with gravel, then moistened sand. Diligently trim.

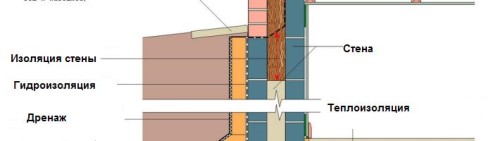

- We cover the sand-gravel pillow with roofing material-horizontal waterproofing.

- Pour the base with a concrete solution.

- Install steel rods around the perimeter with a step of 100 cm and wait until the base is freezed.

- We weld or tie the horizontal reinforcement to the vertical rods, observing the interval of about 300 mm.

- We arrange a strong formwork. We check the verticality.

- Pour concrete with concrete the walls of the cellar immediately around the entire perimeter, otherwise the mounting seams will appear, which will loosen the structure.

- We apply bitumen mastic to the walls or glue the roofing material - vertical waterproofing.

For information: Sometimes a polymer film for waterproofing is placed in the formwork, and then the walls are poured.

Important: to ensure sufficient concrete density, and air sinks were not formed in the walls of the cellar, constantly stir the concrete mixture during filling.

There are other options for the walls of the walls in the cellar:

- Put from red brick, stone or concrete blocks.

- Renew logs or wooden beam. In this case, the tree is treated with special means that prevent its decay.

- Sheathe with asbestos -cement sheets on a wooden crate.

Sometimes they make walls of metal, but then you cannot avoid problems with temperature.

Ceiling for the cellar

Different materials are used to block the cellar:

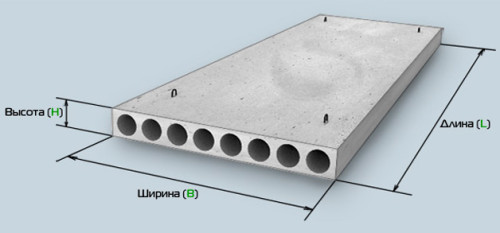

- reinforced concrete slabs;

- durable wooden bars or logs;

- metal profile, etc.

The walls of the cellar are the supports for the overlap, so its dimensions should exceed the quadrature of the room under it. This important stage of construction is carried out in the following sequence:

- We place the channels with an emphasis on the walls with a larger length of 0.5 m from each other.

- We first welcome perpendicular to, and then parallel to the metal profile, the reinforcement so that there are squares with a side of 250 mm.

- We arrange a wooden formwork.

- We introduce 2 asbestos pipes for supply and exhaust ventilation and an electrical box with a wire laid in it.

- We mount rigid supports, the purpose of which is to predict the sort of overlap when pouring a solution with a large weight. We install the supports so that each has an area of \u200b\u200babout one and a half square meters. m.

- We seal the formwork, preventing the seeping of the solution when pouring.

- Pour concrete, filling the entire space in the interval of a channel-armatic grill. We make sure that there is not a single empty corner. In the finished form, the floor is a plate, the maximum height of which is 0.3 m. Such a plate freezes for about a month.

- We insulate the overlap by roofing or other thermal insulation material.

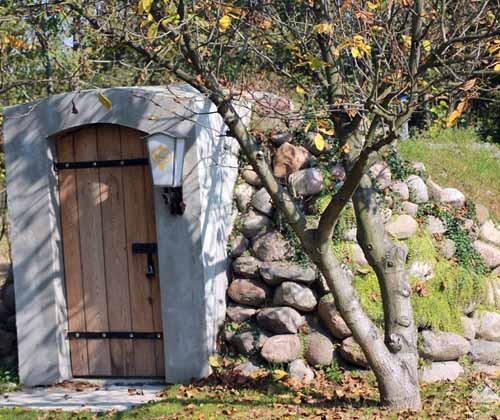

- We fall asleep the finished overlap with the earth, forming a mound or make a roof. Since the overlap was very durable in our country, it can also serve as a foundation for the construction of a small structure above the cellar - a burial made in the form of a house, an arbor or to design the entrance in another way.

The sequence of manufacturing concrete ceiling is set out in this video:

The process of an independent device of reinforced concrete overlap of the cellar is described above, but if there is the possibility of using construction equipment, then ready -made concrete slabs are bought. There is one inconvenience in this option - the dimensions of the cellar will have to be limited by the size of the plates.

It is possible to dig a cellar in the country in the above method only when groundwater is low, and if their level is high, then this option, of course, will not work. For areas where water is located near the surface, a good solution is to build a bulk cellar.

How to build a bulk cellar with your own hands

This type of cellar is performed in 2 performances: vegetable labase, it is also called terrestrial and semi-pounded.

The choice of one of the options depends on the level of groundwater. In this case, one interesting folk method is used:

- Shurf is drilling at least 1.5 m. It makes sense to do this in the spring, when there is enough water in the ground.

- Check in a day, whether there is water in it. If the water appears, you can build a cellar only on the surface, otherwise - you can lay a midnight cellar.

Construction of a ground cellar

If it turned out that the level of humidity is already too high, then there is no other way out how to build an above -ground cellar, the desired microclimate is supported in it due to the layer of the earth, which is dumped the basement. The construction process is schematically looks like this:

- We choose a place on the hill.

- We make markings and remove the soil layer around the perimeter to a depth of not more than 40 cm.

- Adjusting, increase the perimeter by 30 cm on each side.

- We fall asleep into the pit drainage, i.e. A broken brick, crushed stone, sand and just construction garbage, tamp.

- We arrange a brick floor.

- We perform the walls. How the material for them is suitable for small diameter logs, boards, and horseman. Naturally, we process the tree to protect against decay and pests.

- We close the cracks.

- On the outside, cover the walls with bitumen mastic and glue the roofing material.

- We mount a wooden floor and coat it with a mixture of clay with straw.

- We coat with clay -bearing mastic and cover with roofing material.

- We fall asleep the layer of the earth on which we sow the lawn grass.

We build a half -jacket cellar

Most often they build half -glued cellars in the dachas, photos taken in different areas show how this option can be beaten, turning it into one of the elements that harmoniously fit into the design and decorate the site.

The feasibility of the device of a half -jacket cellar is justified by a high level of groundwater location on the site, when it is impossible to delve into no way lower than 1 m. The algorithm is this:

- Prepare a pit 0.7 m deep.

- We arrange a brick or concrete base.

- We build the walls to a height of 0.22 m, not forgetting to leave the opening door in one of them.

- We isolate the bottom and walls.

- We build an overlap that is easiest to make from a hump with a thickness of 5 cm, then:

- pour a layer of clay;

- we cover with two layers of roofing material;

- we fall asleep with soil to a thickness of 0.7 m;

- we put the design with a turf.

6. We insert the door, build a canopy above it, make steps.

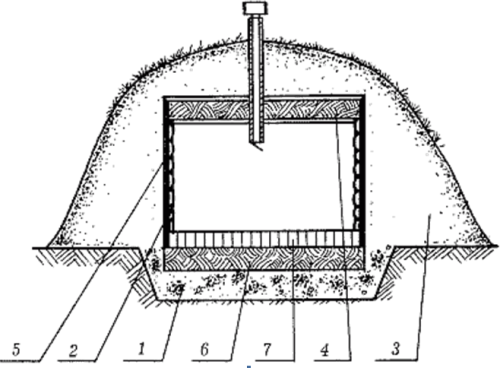

Below is a sketch of the aboveground cellar:

Here:

- 1 - pillow of crushed stone, broken brick or sand;

- 3 - soil;

- 4 - a mixture of clay and straw;

- 5 - waterproofing;

- 6 - fatty clay playing the role of the castle;

- 7 - a floor of brick installed on the rib.

Such a cellar can be attached to the house or garage, then only 3 walls will have to be erected.

The construction of all these cellars requires considerable physical effort and the availability of free time, but there is another option that allows to significantly speed up this process. We are talking about a plastic cellar. Let us consider in more detail its advantages and disadvantages.

Plastic cellar for giving

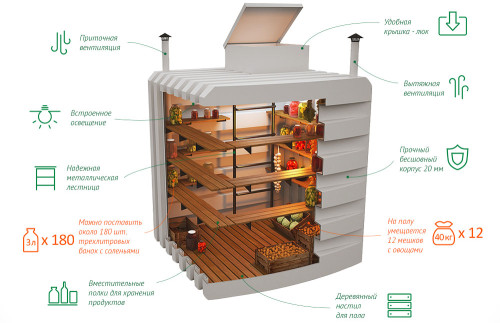

Plastic cellars are chambers with wall thickness of a maximum of 1.6 cm. The shape is different. There are structures with or without stiffeners. The equipment of individual products is also different: they can have a lid, shelves, a staircase, a finished ventilation system. Popular dimensions - 150x150x150 and 200x200x200 cm.

The advantages of the design

The advantages of this design are expressed as follows:

- The place of accommodation is chosen where it is convenient for the owner, and not depending on the location of the groundwater.

- The installation technology is very simple compared to the device of the traditional cellar, because The need for many works is no longer.

- The kesson does not have temperature and humidity changes.

- Microorganisms and pests do not settle in it.

The disadvantages of Kesson

Before making a decision on the purchase of a plastic cellar, think about whether its minuses are arranged:

- the cost is considerable, it will cost 25 percent more expensive than with your own hands;

- standard dimensions;

- if you install it incorrectly, then high groundwater can oust it from the pit.

Experienced advice

In order not to regret the acquisition, listen to the advice of people who already have such happiness as a plastic cellar for a summer residence:

- pay attention to the quality of the material, check certificates, GOSTs and other documentation;

- for installation, invite specialists;

- to monitor the quality of work, it is good to have a familiar professional in extreme cases of a person in no way related to a working team;

- to protect yourself from problems, conclude an agreement with the installers and pay attention to the guarantees that they provide.

Manufacturers of the cellar

A plastic cellar can be bought or ordered. For example, the Russian Aqua Hold company produces cellars in 3 performances:

Barce cellar

- Rectangular plastic with a thickness of 10 mm.

2. The cellar in the second performance of a cylindrical shape made of a pipe with polyethylene, spiral with a wall of at least 2.5 cm, height at the request of the client.

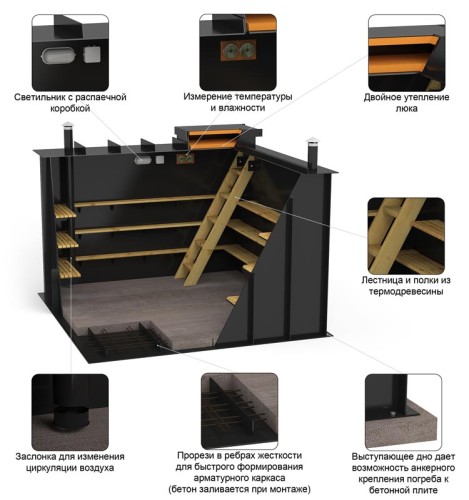

3. The third cellar is rectangular, cast, made using a rotoformal machine. It has stiffener ribs and a protruding bottom, which reliably protects the caisson from surfacing.

Tinger cellar

The Tinghard polymer products plant produced good plastic cellars. The main advantage of Tinger’s cellar is that it has no seams, which means that it does not threaten the penetration of groundwater through a poor -quality connection.

It is impossible to build a cellar in the country, not knowing the basic principles, its arrangement. The author of this video shares useful knowledge about this: