Facade decoration is an important question that excites all owners of private houses. I would like to use inexpensive, but at the same time reliable material that will provide protection against negative environmental factors and give the house an original appearance. One of the best solutions will be the use of plastic siding.

Content

Features of the material

Siding was developed as a substitute for a classic wooden lining, so it is largely similar to this building material. Panels from various polymeric foundations are made. The cost and characteristics of the material depends on their quality and physical and chemical properties.

In general terms, it is worth noting:

- high resistance to ultraviolet, the color does not burn out even under the direct exposure of sunlight;

- wide temperature regime, from -50 to +60 degrees Celsius;

- service life is at least 60 years;

- environmental friendliness, there are no evaporating benzene junctions;

- relatively low cost.

The correct name of the material is vinyl siding. For the first time he went on sale in 1959 and has since passed several significant modernizations.

Of the circumstances that speak in favor of buying a plastic siding, it is worth highlighting:

- not susceptible to acids and alkalis;

- not susceptible to temperature fluctuations;

- does not crack, does not peel off, does not delay;

- withstands mechanical damage to moderate severity, such as the hit of the football ball;

- does not rot and does not corrode;

- does not absorb moisture;

- does not conduct electricity;

- easily mounted and does not require update.

The disadvantages are customary to include:

- lack of noise and thermal insulation;

- exposure to burning;

- not too presentable appearance.

But the last remark is true only with respect to the plastic siding, the price of which does not exceed ordinary ceiling panels.

In fact, the similarity of the distillery and ceiling panels gave rise to most myths about unreliability and poor quality of the material.

Types of plastic siding

Vinyl panels according to the manufacturing principle are divided into:

- monoecstrusive;

- polyextstrusive.

The first option is extremely rare, since finished products do not have high technical characteristics. The polyeststruse method of production involves the presence of a special apparatus - an extruder, which gives a polymer base for two boxes preheated to a liquid state.

In one of them, the polymer is mixed with protective components and additives, in the other it is enhanced by heat -resistant additives. Of the boxes, both blanks are fed to the conveyor tape, where they are combined at the molecular level. The result is a two -layer high -strength panel.

By the method of fastening, it is divided into:

- christmas tree latch;

- the latch is like a shipboard.

In practice, both options differ exclusively by localization, the Christmas tree is characteristic of the USA and Canada, the shipboard for Europe. There are no differences in strength or other characteristics.

Another possible classification, according to the texture of the front part:

- flat;

- relief.

Relief panels, as a rule, imitate raw wood or stone.

Siding is plastic colors

Given that any polymer is excellently tinted, the color palette is almost unlimited. For convenience, we use the following classification:

- monoxide;

- polycolor;

- vinyl colors;

- immitations.

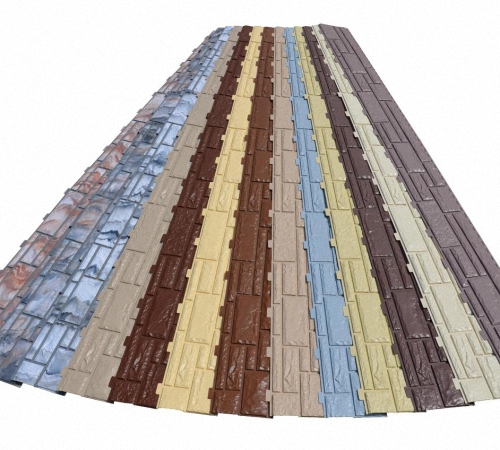

Monocouple is more common than others, since their production is considered the cheapest. In addition to the standard palette, it is possible to choose options for marble crumbs, and other expensive types of finishing materials. A plastic siding, a photo of which is presented below, shows a variety of design options.

Tip: When choosing such panels, it should be borne in mind that if there is no color in one store that you like, it will certainly be in another.

Polycles are achieved by combining plastic siding of one series. Experts use this technique to create unique mosaic compositions.

A distinctive feature of vinyl is the reflection of sunlight in such a way that the paint begins to shimmer. In the free sale of such panels, it is almost impossible to find, however, there are special films that allow you to achieve the desired effect.

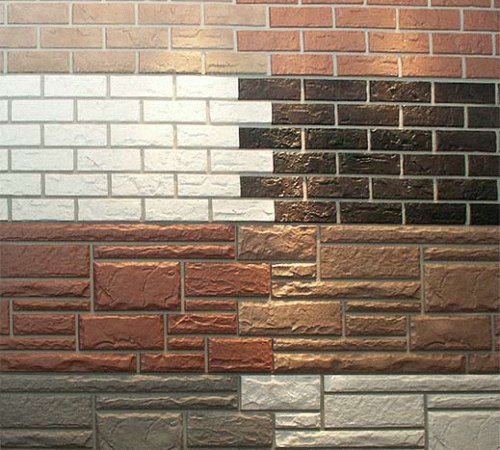

I simulations, despite the fact that it transfers the texture of natural materials, is at the level with other types of plastic siding. Happens:

- under the log;

- under stone;

- under the brick.

Plastic siding under the log, in turn, is divided into two subspecies:

- natural log;

- glued beam.

A natural log has a rounded shape, glued beam - square. When choosing such panels, you need to pay attention to filling. Very often, manufacturers save and leave voids, this should not be. Any space between the load -bearing wall and siding can be used by insects and small rodents to arrange the nest.

Tip: Some solution to the problem will be the use of mounting foam. The properties of the material make it unsuitable for the life of pests.

Plastic siding under a stone repeats the outlines of natural stone laid on a cement mortar or a monolith method. There are quite a lot variations of execution, from flat shale or granite to a ornate basalt with original veins and interspersed of other breeds.

Tip: It is better to choose this variety of siding in online stores, since there is the opportunity to see the battle of several variations from various manufacturers.

Plastic siding for a brick is also a fairly common type of decoration of vinyl panels. The main model line is red brick and clinker. But there are other options for execution. The subspecies of this design is an imitation of tile decorative tiles.

Siding plastic manufacturers

Since the technology was developed in Canada, this country is an unconditional leader in product quality. This circumstance affects the price, but investments will be justified. Since there are no complaints from users. Among the most popular firms are highlighted:

- Mitten;

- Vytec;

- Gentek;

- Novik;

- Kaycan.

The average cost is $ 30-40 per panel.

A little worse vinyl siding from manufacturers from the USA. Differences are so insignificant that they can manifest only after 20-30 years of use. During this time, most likely, you will need to do at least cosmetic repairs. Best companies:

- Variform;

- Georgia Pacific;

- Foundry;

- Nailite.

The average cost is $ 30-35 per panel.

The Americans, unlike Canadian factories, also produce an economy series. This product cannot boast of high quality and only a little superior to domestic analogues. Among such manufacturers:

- Elixir;

- Heartland.

The average cost is $ 25-30 per panel.

Domestic manufacturers recently are also engaged in the manufacture of vinyl siding. All factories can be divided into two large groups:

- those who work with foreign raw materials on imported equipment;

- those who work on domestic equipment using polymers of production of the CIS countries.

There is no need to talk about the quality of products of the second option, so we will present a list of firms that should be trusted:

- Alpha profile;

- Deck;

- Holzplast;

- Nordside;

- Wall;

- Fine Ber.

The main production capacities of most enterprises are in Tver and the region. Against their background, Nordside, located in St. Petersburg, favorably differs. It offers customers a truly high -quality product, in their characteristics, maximally complies with the standards established in the West.

Siding is plastic and its installation

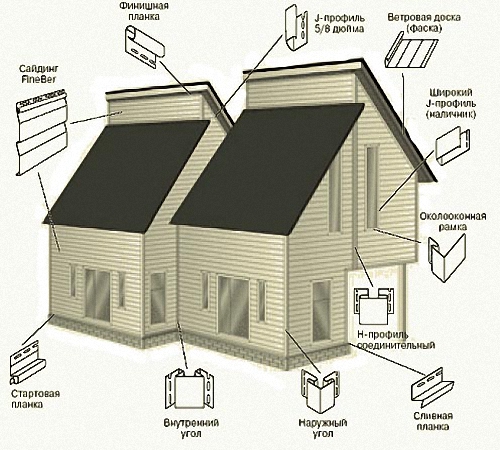

From a technological point of view, the use of siding is the simplest type of facade decoration. The kit consists of:

- panel profile;

- external corner;

- inner angle;

- start profile;

- finish profile;

- additional fasteners.

The installation of plastic siding with your own hands begins with the preparation of the base of the walls. Since the hinged panels will prevent the normal process of gas exchange, and in the absence of vapor barrier, they will also cause condensate formation, it is necessary to treat the surface with protective, antibactericidal primer.

Next, consider the instructions on how to fix a plastic siding:

1. Install additional fasteners in terms of level.

2. Fix the panel in them.

3. Fill the panel to the wall using screws and dowels, if the wall material is wood, there will be enough construction scholarship.

4. Perform the same actions and fix the next panel.

5. Installation is carried out from the roof to the basement in order not to cut the panels.

As a rule, the base has a different design from the rest.

Tip: If additional fasteners are not provided, then the panel is installed in level. To do this, one of the edges is screwed, and the second is adjusted to the right angle. For this work, two people are needed.

Tip: plastic siding, the dimensions of which rarely exceed 4 m, must be unable to connect with a special seam, without it, moisture and parasites will fall under the vyil.

After one of the walls is sheathed, the outer or inner angle is installed. Siding is coming from him to the next wall. Since neither construction solutions, nor adhesive, nor plaster are used, the design is completely ready for operation immediately after the end of the installation. According to reviews, the installation speed of the panels is quite high and is about 8 linear meters per hour.

Possible problems

Regardless of the visual design of plastic siding, the mounting mechanism is always the same. Nevertheless, there are irritations on how to carry out installation work. This leads to the fact that the technology is violated. As a result, there is a risk that the panel will fall off, burst or jump out of the groove.

Since liquid nails work faster and less dirty than dowels, many use them to fasten the panels. What of this turns out? The adhesive mixture is knitted with a stone or plaster and a panel. The mount is carried out pointwise, and in places not provided for this. Since the formation of condensate is inevitable, a stone or plaster will begin to crumble. This process will lead to the exfoliation of the panel.

Vinyl can burst only if it has not enough fastening points. It is very important that the panel does not sag, otherwise an excess load is created, which, at the slightest blow, will lead to the formation of cracks. Such damage is not subject to local repair and require replacement of the entire panel.