The railing is an important part of the stairs. They strengthen the structure and serve as a support for people. Correctly executed railings will decorate the staircase and interior of the house. They are made from different materials and, in accordance with its design, have all kinds of shapes and sizes.

Content

Do -it -yourself railing for the stairs - preparation for work

Tools

When installing the railing, you should prepare the tools in advance:

- chisels;

- hacksaw and chisel;

- hammer;

- screwdrivers;

- screwdriver;

- drill;

- drill;

- lobby;

- level;

- sensor tools - roulette, pencil, marker.

Material

When choosing material for the railing, several factors should be taken into account:

- design features;

- interior style;

- the complexity of installation - this moment is especially important with independent work.

The materials from which the railing for the stairs are made:

- tree;

- metal: steel, aluminum, chrome metal;

- forged iron;

- glass;

- plastic.

Details of the structure

Elements that make up any staircase railing:

- Stoppieces-installed at the beginning and end of the staircase march. They account for the main load, so they should be very stable. For reliability, the cabinets are often installed on an additional platform. Its height is 80-90 cm. This is an average parameter in which it is convenient for a person to climb the stairs, but if desired, it can be changed.

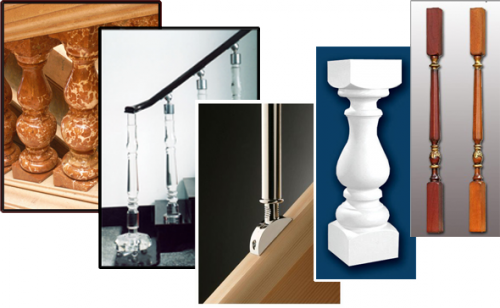

- Balyasins - columns that are installed along the stairs and support the railing. They come in any shape: round, square, flat or curly.

Wooden balusters are often decorated with manual thread.

The distance between the columns is different, but it should not exceed 20 cm. One of the options is a continuous baluster.

- The handrail is the upper part of the railing, the size of which corresponds to the length of the staircase march. It is round, rectangular and even carved, but the main goal of this detail is the convenience of users. It is he who is a support for the stairs.

How to make railing for stairs

Wooden railing for stairs

The choice of material

For the manufacture of the railing, various wood of wood are used: spruce, fir, poplar, nut, etc. But the most reliable products from oak, ash or tick are considered. Solid rocks allow you to create thin, but safe details, and the railing of them has an easy, elegant look.

Installation of the fence of the stairs

- At the end and beginning of the march, cabinets are installed. To check the chosen height, the cord is pulled between them and a trial lift is carried out and the launch of the stairs is carried out. The cabinets are attached and checked for stability - their "staggering" is unacceptable.

- The bowstring (lower support) is attached with screws to the staircase march and cabins.

- The frequency of balusters is calculated, and holes are drilled under the handrail.

- The end edges of the balusters are drank at an angle equal to the inclination of the stairs. When fastening the racks to the steps, their lower part is left straight.

- Balyasins are installed using studs, which are screwed into their base and inserted into the prepared hole in the stairs. They are tightened with nuts on the bottom of the structure. Another fastening option is the use of spikes and recesses in a bowstring and handrail.

- The railing is installed and fixed to balusters.

- Ready -made fences are cleaned of dust, all visible flaws on the surface are put off and varnished.

Rail fastening using nails is the easiest way to assemble them. But it is the most unreliable, because after a short time the structure becomes unstable. Special studs, spikes or screws planted on the adhesive will provide a more durable fastening of parts.

Metal railing for stairs

Material

Metal railings are already purchased ready -made or ordered in the workshop - it is very difficult to make them independently. These designs are made of various material, which has its pros and cons.

- Aluminum - has a small weight affordable. The railing from this material is diverse in form and configuration, but not very durable.

- Stainless steel is beautiful, durable and resistant to moisture. It has one drawback - high cost.

- Stained pipes are reliable and affordable, but require regular renewal of the coating.

- Nickelled pipes are beautiful and not very expensive compared to the "stainless steel", but are subject to corrosion.

Installation of the railing

- On the steps of the stairs, in the places of installation of balusters, markings are made.

- Holes are drilled in the marked places.

- The dust that appears is blown up by an industrial vacuum cleaner.

- Two -component glue is poured into the resulting hole, and studs are inserted.

- With the help of a screw or welding on the studs, racks are attached. Using the level, their vertical position is controlled.

- A handrail is attached to the support bolts. Welding is rarely used, since it requires certain skills.

- The welds are cleaned and polished.

Forged railing for stairs

Forged railing is mounted with welding. Elements for them are sold in stores or workshops. But the best option is to order the railing from the blacksmith. According to the proposed drawing, the masters will buy a unique product that will be a unique decoration of the house.

Welding work on the installation of the railing does not require special professionalism - it is enough to have small skills on them. But it is very important to carefully approach the finish of the finished design. With properly selected materials for priming and crushing the railing, they will last many years without changing the appearance.

Railing for the stairs, photo: