In the absence of gas and interruptions in the supply of electricity in some regions, the wood stove remains the only alternative not only for heating the room, but also for cooking. A solid fuel furnace, which is equipped with a hob, should have a special design. Just attach a sheet of metal to a regular plate and try to cook on it - it will not work. The fact is that the release of heat during the burning of solid fuel in various parts of the furnace occurs unevenly, so cooking on such a plate will not be too comfortable and productive. A special problem in the use of such heating devices occurs in the summer, when the furnace should be given more to the hob, and not to heat the room. Otherwise, the kitchen on hot days will turn into "hell".

Content

Currently, there are a large number of projects of solid fuel furnaces that are adapted for cooking. Each experienced stove -item offers its own design, but it often happens that it is not tested by time and cannot give good results. About how to choose a project for a hob of a solid fuel furnace and mount it independently - further in the article.

Types of cooking furnaces

Due to problems with temperature adjustment, stoves on solid fuel are found only in places where there is a problem with coolant traditional for these purposes. For cooking, as a rule, the furnace is laid out so that it has a small niche under which the firebox is located. In the summer, when the stove is not completely heat focuses on the hob, which allows to reduce heat transfer in the oven channels so as not to heat the room. With the onset of cold weather, thermodynamic resistance shifts towards the channels of the furnace, due to which the room itself occurs. When using the furnace as a heater, the amount of fuel used allows you to warm the hob for comfortable cooking.

The most common models of hobs of solid fuel furnaces are Swedes. They are laid out of refractory bricks with a complex system of channels, which allow more rationally the use of heat.

Based on the material of manufacture, the most popular species are heating and welding brick furnaces. However, recently, more advanced metal models have appeared. Thanks to the system of burning pyrolysis gas, which is released when fuel heats, the operation of such a furnace on one load increases significantly. Due to the normal distribution of heat, the efficiency of such furnaces is quite high, which allows them to be used both for cooking and for heating the room. When building a heating-welding furnace, a slightly smaller amount of chamotis brick in the total mass of materials is used. The fact is that chamotum brick has a very large heat capacity and small thermal conductivity. Because of this, it works as a heat accumulator, which is very good for heating furnaces and not too much for heating-welding.

In addition to the material from which the furnace is built, these designs are divided by the degree of mobility.

- Stationary furnaces. As a rule, stationary furnaces are built from refractory bricks indoors. They build such devices on a separate foundation, so they stand for a very long time. The advantages of stationary furnaces are their high efficiency, as well as the strength of the structure. However, they are quite bulky and occupy a large area.

- Transported. Such furnaces can be transported their place to the place without analysis of their main design. Usually made of steel. A significant advantage of transported furnaces is their mobility. If necessary, they can be delivered and installed anywhere. Among the shortcomings, one can note large dimensions of the furnace, which do not allow them to transport them without special lifting mechanisms and trucks.

- Collapsible furnaces. Also mainly represented by steel models. Thanks to the collapsible case, it can be easily transported and installed even in an unprepared place. The disadvantage of such furnaces is their low efficiency by facilitating the structure.

Hobs of any furnaces are made of ferrous metal. In order to cook food and heat it, different temperature conditions are needed. This is achieved by using different metals for the hob. It is made of cast iron with special steel inserts. Since cast iron has lower thermal conductivity, it is used only to warm up food. In a cast -iron plate, special holes are made into which steel rings are inserted that form the burners. The thermal conductivity has much larger, due to which the surface of the firewood heats up much more intensively. Thanks to this, the hostess has at least some temperature adjustment method.

Swedish heating-welding furnace

A distinctive feature of the Swede is the presence of an oven. The fact that Swedish academics were engaged in the development of this design in the 18th century. The oven in such furnaces is a kind of switch from winter to summer move.

The oven in the design of the heating and welding furnaces acts as an aerodynamic barrier for outgoing gases that rise from the furnace. Thanks to this, they completely burn out the furnaces under the arch and go into the channels of the stove with high temperature. That is why, in such furnaces, you can arrange a double wall behind the oven, in which you can place heat exchangers for heating water.

In Swedish furnaces in winter, the hob does not warm up excessively, which allows you to cook normally. In the summer, thanks to the placed oven, the hot gases do not fall into the channels of the furnace, but only heat the hob, which increases its efficiency. This is achieved thanks to a small laying of fuel.

When using this furnace, it is necessary to take into account the fact that each of the confer is heated unevenly. That of them, which is located directly above the furnace, heats up much stronger, and is suitable for frying, the second is perfect for cooking.

In winter, such a stove works perfectly on any form of solid fuel, both on firewood and coals. But in the summer, it is better to use small portions of coal or wood briquettes. Firewood is not too suitable, since the dried material burns too quickly, giving less heat, which leads to a large fuel consumption. With proper masonry and the design of the Swedish furnace, the room warms up in the summer no more than when using gas.

One of the main stages of the construction of the Swedish furnace is to fill the foundation. Since the weight of the furnace is quite high, it is necessary to work on the construction of the base. A cement-sand screed is built to the level with floor flooring. A layer of asbestos cardboard with a thickness of at least 4 mm is laid on the screed. It should go to the furnace: from the sides by 300 mm, from the front side (in front of the firebox) at least 600 mm.

Next, a layer of foil or a thin galvanized sheet is laid, and a layer of asbestos or mineral cardboard again on it. Then a layer of roofing iron is laid, and a felt on it. Before laying, it must be soaked in clay milk - a liquid solution of clay. He serve as a kind of protection against heat loss.

The masonry of the heating and welding furnace is carried out by several levels, each of which has its own scheme.

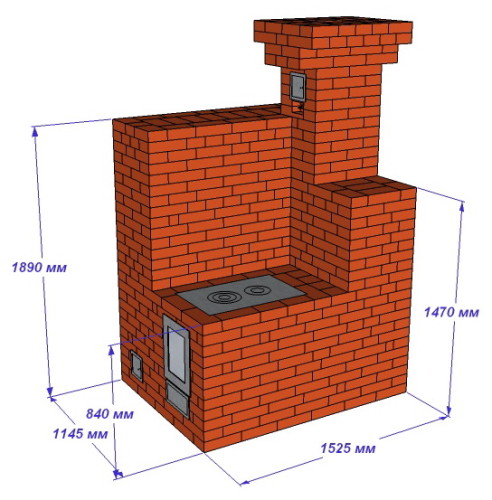

For the construction of the middle "Swede" you will need:

- Full -bodied brick M150 - about 600 pcs.

- Clay-sand mixture for stove masonry-about 200 kg.

- Steel corner 40x40 mm - 2 m.

- A steel strip 50 mm wide, 5 mm thick - 1 m.

- A sheet of roofing iron.

- List of flat slate.

- Special furnace instruments (grates, doors for furnace and treatment chambers, valves, hob, burner).

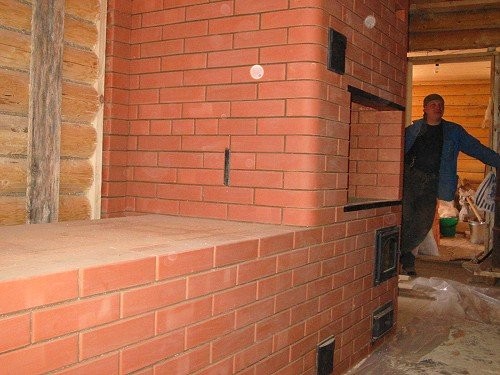

Simple heating-welding stove with your own hands

Such designs do not have special gas output channels, so they are not suitable for heating the room. Usually they are built in dachas, suburban houses in which there are summer kitchens.

Thanks to this design, you can significantly save brick. For all construction, it will need no more than 250 pcs. Given the reserve in case of battle. The weight of this furnace is not too high, which does not imply an additional load on the foundation of the house. When constructing a furnace only for cooking, the refractory layers of the foundation are located in a different order. The first layer is laid by a felt on which steel is laid. On a steel sheet and begin masonry. Asbest in this case is not too suitable, as it has a poor clutch, which is why the stove can simply “go”.

This design perfectly warms up the oven in which you can even bake pies.

Due to the good efficiency in such a furnace, heat exchangers can be installed for heating water. In houses in which it is sometimes planned to stay in cold weather, you can install a heating shield that will contribute to the distribution of heat indoors.

Design of hobs

Although, at first glance, the construction and design of the hob is not difficult, this is not quite easy. Without knowledge of thermodynamics, the conditions of combustion of this or that fuel, it will be problematic to draw up such a project. For each individual house, it is necessary to accept its conditions so that fuel combustion gives maximum return. That is why typical projects of solid fuel furnaces that can now be found in the literature may not be suitable for a particular house. It is better to contact experienced stoves with this problem, then it will be sure that the furnace will work for a long time, efficiently and safely. When preparing projects of heating and welding furnaces, you need to know all SNiP standards so that when putting a house into operation, there are no problems with the regulatory authorities.