Quite often, plastic windows after installing them require an important stage of work to complete the integrity of the structure. Installation of slopes on the windows is not included in the standard list of services, and many construction companies require separate payment, while not stingy with the figure. Nevertheless, they are quite capable of establishing them yourself. It is important to know the subtleties of the process so that in the future such slopes do not freeze or accumulate condensation due to possible mistakes.

Content

Problems with incorrect sloping installation

Determine the incorrect installation of slopes is quite possible visually. Often the problem is manifested itself and in this case it is necessary to take urgent measures to eliminate it. We will analyze the most common defects:

- The appearance of condensate at the junction or seam of the slope. Excess moisture is formed due to the temperature difference inside and outside the room, and contributes to seeping through a poorly laid insulation. In this case, the design of drywall are of particular danger, since this material is characterized by a high degree of absorption. In this case, the responsibility lies on the installer of windows, who did not take care of high -quality sealing of the joints and laid either an insufficient amount of insulation, or completely neglected it.

- The freezing of slopes on plastic windows is caused by the penetration of cold air in winter through the voids in the mounting seam. If the mounting foam outside the building protrudes outside the tide, then under the influence of ultraviolet radiation and weather conditions it begins to collapse. In this case, the formation of voids is likely, through which winter air will directly enter the slope design, which in combination with warm air inside the room will cause condensation and further freezing.

- Lack of foam in some places when installing an ebb. The mounting foam has the properties to penetrate into any voids and fill them, but in the event that its blowing was carried out inaccurately, then there is a free space that leads to the appearance of drafts.

- The main problem in manifestation of humidity is the formation of a fungus or mold. This has a poor effect on the human body, and besides, the fungus affects the structure of the walls and ceiling, contributing to the appearance of microcracks and their further destruction.

- Increased noise. The formation of voids helps to penetrate air and noise from the street, while reducing the effectiveness of sound insulation.

As a rule, problems arise due to poor quality work of installers, so it makes sense either to contact specialists with a good reputation, or to provide personal control at all stages of work. If the work is carried out independently, then the accurate and thorough filling of all voids with mounting foam with its subsequent decoration will become useful.

Materials for window slopes

The following varieties of slopes are most widely used:

- plasterboard,

- plastic,

- slopes from sandwich panels,

- substacked slopes.

Plasterboard products differ in cheapness and ease of installation, but due to insufficient hardness of the surface, damage is easily formed on them. In addition, drywall is characterized by increased absorption, so it will not be easy to clean the marks of dirt. In addition, drywall also absorbs moisture, so it is necessary to use either moisture -resistant varieties or refuse to install structures from this material in places with high humidity.

However, such slopes are most popular for a number of reasons:

- speed and ease of installation,

- allow for additional insulation,

- the environmental friendliness of Matearila,

- the possibility of cosmetic and restoration repairs.

Plasterboard products are durable and their practicality. They are easy to paint and they do not require special installation skills.

Plastic models have gained popularity, as they have a low cost and allow you to create a single design with a window or door leaf. To ensure additional thermal insulation, plastic will require laying of the foam or mineral wool.

Sandwich panels are interesting in that they have a porous structure. Thanks to it, they better maintain heat, and many manufacturers, in addition to glossy or matte, offer slopes with a surface that imitates a tree. Like simple plastic ones, the panels are also easily mounted.

Plassing - the process is quite time -consuming, but still retained a significant number of adherents. It should be noted that plaster has one advantage over other methods - the total cost of creating such slopes will be much cheaper. In all other ways, it is inferior to indicators of products made of plastic or drywall.

Installation of slopes

If the window slopes on the windows are not included in the standard installation of a metal -plastic structure, then some people begin to wonder: how to make slopes on the windows without resorting to the services of specialists. Such work is quite capable of doing it yourself, but some points must be taken into account:

- when living in a typical apartment on the floor above the first, independent installation of external slopes will become a dangerous business, so this work needs to be entrusted to specialists,

- there is no need to neglect the means of protection. Plastic is unpleasant in that with its cut, small particles are formed that can get into the eyes.

After the decision on the installation of slopes on the windows was made using your forces, then you need to decide what type of material will be chosen for them.

Plaster slopes for a plastic window

The method of manufacturing slopes from plaster is already morally outdated, since modern materials have more advantages and that are important, noticeably faster. For example, if the installation of a window slope made of plastic or drywall will take 3-4 hours, then plastering work takes a day or two.

But adherents of this method still extol his dignity:

- high mechanical strength,

- durability,

- the low price of the material, which is $ 5 per bag weighing 30 kg.

It is necessary to have minimal building skills in order to qualitatively carry out all the stages of preparatory work:

- the surface for the installation of slopes is cleaned of garbage and construction dust,

- the remains of stone crumbs or concrete are removed from the surface with a spatula and a boot knife,

- the excess foam formed after its solidification is cut with a knife,

- next, the surface is subjected to preliminary primer.

This helps to improve the adhesion of the material, so that the plaster is better to clarify with the surface.

Then they are already starting to make slopes from plaster. All work is divided into conditional stages:

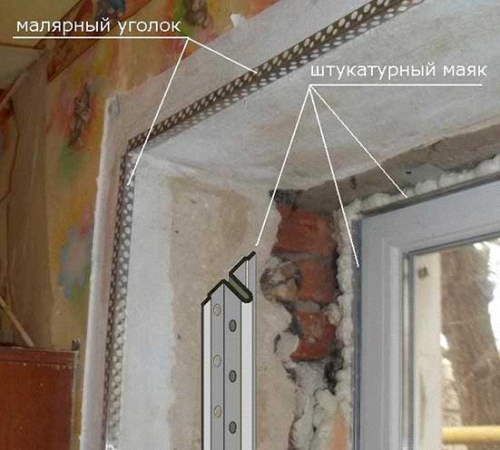

- Wooden rails are installed on the solution or other adhesive base to set the level. In the future, they will play the role of signal beacons and must be carefully fixed on the surface in order to prevent displacement.

- For work, Malki are made, which are an even wooden rail with a nail driven into it from the side of the end. In this case, Malka is a rule, while the nail sticks out of the bar to 5 mm. In order to protect the window frame from scratches, a heat mustache or vinyl tube is dressed on the protruding part of the nail. The role of Malkalka is to evenly distribute the solution, while 5 mm of the composition should fall on the base of the window frame.

- Next, plaster is applied to the surface, which is evenly distributed by Malkalki on the surface. At the same time, her surplus is removed in a timely manner.

- After preliminary hardening, the slopes are wiped with a simple grater. Thanks to this, the surface acquires a homogeneous structure.

- After the surface is hardened, the rails are removed, and all the corners are corrected using a solution.

- The slopes are put down and prepared for painting.

- The finished surface is painted in two layers. It is recommended to use special rubber paint, which has the following advantages compared to the usual:

- due to its structure, it is resistant to deformation when exposed to severe heating or freezing,

- rubber paint does not crack when damaged,

- it differs more durability.

Lining of slopes using drywall

The use of drywall for the manufacture of slopes will significantly reduce the time for their construction and will not require such complexity as the method specified above. The following tool will be needed for work:

- screwdriver with a bat for self -tapping screws,

- spatulas 50, 100 and 200 mm,

- rags,

- mounting or boot knife,

- grater for rubbing,

- welding screws 10 mm long.

After preparatory work aimed at cleansing the surface, you need to start installing the starting strip. It is intended for visual control of a tight fit of the sheet to the surface. With the help of self -tapping screws, it is confused to the window frame. Next, the response bar is mounted. Fix it along the edge of the wall. The resulting design will provide the necessary level and replace the beacons. In order for the drywall sheet to be bent, the strips are connected by transverse crossbars. Install them at a distance of 30 cm from each other. In standard apartments, as a rule, they make the upper, lower and two central ones. In the apartments of the old fund it all depends on the height of the window.

There is a simpler way to install drywall slopes. To do this, it is enough to cut 10-20 small squares of gypsum. Next, the squares are evenly glued to the wall. Be sure to install one in each corner and distribute 5-6 on the surface of the slope. Then put a sheet of drywall, set the level and look at how much and where it is necessary to drift the squares. When the preliminary work is done, they proceed to gluing the slope itself. To do this, glue is applied to squares, and the space between them is blown by mounting foam. After installation, a sheet of drywall should be fixed with a spacer so that the foam does not squeeze it out. This method allows you to create slope with higher energy efficiency and sound insulation. In addition, the possibility of siphons and drafts is completely excluded.

The finish stage is suture plaster and gypsum plastic painting. If the slope is not white, but color, initially you still need to paint it in 1 layer with white paint. Then 2 layers of color are painted along it.

The finish of the slopes with plastic

The decoration of the slopes of windows with plastic elements has gained the most popular due to their lightweight, strength and durability. Unlike other varieties of slopes, the installation of which must be carried out 36 hours after installing the window, plastic are installed immediately after the installation of window sashes. To do this, the perimeter of the frame is soldered and even strokes are cut off using a knife. Next, glue is applied to them. Plastic elements are fixed using protrusions on them. Or the slopes with liquid glue are directly glued to the surface and fixed with the help of snapping corners.

The slope panel itself should have the following structure:

- PVC coating of the same color scheme and texture as the window profile,

- insulation made of mineral wool or polystyrene foam,

- pVC sheet resistant to moisture.

Plastic elements are convenient in that they can be dismantled and re -install, without resorting to additional actions. Suppose this is done in the case of the wallpaper or other internal repair of the room.

Installation of slopes from sandwich panels

Such panels are interesting in that they have manufacturing styles with imitation of the textures of different materials. In addition, they better maintain heat in the room and prevent the formation of condensate.

Like simple plastic slopes, the installation of sandwich panels is carried out using the same technology. The slope is attached to the starting profile, filling the free space with insulation, which is laid for plastic. Then, with the help of self -tapping screws, the outer part of the slope is attached, I hide with the help of plugs of the self -tapping hat.

If the installation of panel slopes on the windows, the video with the installation of which can be seen just below, involves the use of brackets as accessories, then the installation is carried out somewhat differently.

The brackets with the help of a double -sided mounting tape are attached with one side to the slope, the second to the wall, connecting them to each other with self -tapping screws. The side parts of the PVC of the slope are fixed on the windowsill using liquid nails. After that, all the cracks are worked out by sealant, while gently removing the excess using rags and the slope is fixed.