Slopes on the windows are one of the most difficult processes at the final stage of finishing work. The window opening inevitably receives damage, even with a neat replacement of the window. The cost of decorating slopes is slightly higher than ordinary plastering work. But, the question of how to make slopes on the windows correctly excites many stringing owners.

Content

Two types of guides for window slopes

- In the first case, use perfectly even boards or rails. Using the level, the guides are exhibited along the extreme edge of the window opening. For the correct formation of the guide circuit, a malk is used, specially cut in the desired size.

- Malka is cut out of plywood or flat hand with the most correct corners, straight and even. When pouncing a plaster solution, the straight edge of Malkayka sets the smooth surface of the window slope. For fasteners, nails or screws are used.

- In the second case, the guides are exhibited from the painting corners and plastering lighthouses. According to the guides, the plaster mass is made by the Kelma and is leveled by the rule. The plus of this method is that the guides are walled up in the body of the slope, and performs reinforcing corners, which are always a sick window of the window opening.

To perform work on the decoration of window slopes

Materials:

- A bag of plaster mixture or glue for tiles. Better water and frost -resistant.

- The finished putty (1-2 kg) is also suitable for an acrylic finished mixture.

- Plot - 1 liter. Not only deep impregnation, but also water -repellent and antifungal.

- Reinforced fiberglass grid No. 80 or No. 100.

- Water -based facade white paint 1.2 kg and dye - pigment.

- A little gypsum or alabaster, expense materials: nails, screws, sandpaper, etc.

Tools:

- Stainless steel spatula, narrow-(4-5 cm), medium (8-10 cm) and wide-(25-30 cm).

- Torok or Kelm.

- Rule, grater.

- Malar brushes.

Finishing external slopes of windows.

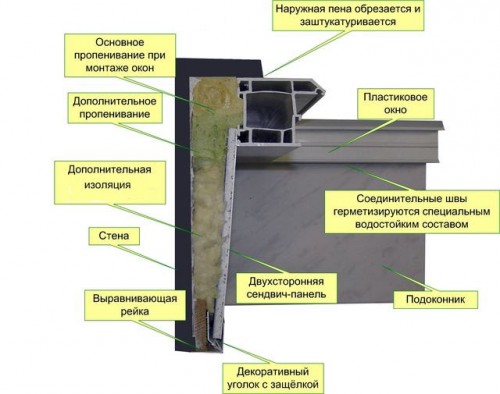

- After installing plastic or wooden windows, as a rule, they are now installed on the mounting foam, the protruding bugs of frozen foam with a knife for drywall are removed. According to the contour of the window, the junction is sealed with silicone sealant or polyurethane tape with the effect of self -expanding (Psul).

- But, adhesion of facade paint does not provide absolute protection. The ideal option is to use frost -resistant glue for tiles. External slopes of the windows are made by a wet method.

Plaster of the slopes of windows from the inside

- Simple plaster of the slopes of the windows is distinguished by its simplicity. To do this, you need a dry stucco mixture based on cement and putty. It is enough to dilute it with water until the consistency of the thick sour cream and the mixture is ready for plastering work. Windows start decorating the windows after the complete completion of plastering work on the ceiling and walls.

- The surface of the slopes is cleaned, the protrusions are removed, and large cracks and pits are covered with alabastr. A corner edge of the slope is finished along the perimeter of the window opening. The plastering layers are applied one after another, after the previous one dries, so the work on the decoration of the slopes can be delayed for two to three days.

- Lighthouses are exhibited and strengthened in level. It is necessary to take into account a small ramp from the box to the corner of the slope. The angles of the dawn of the slopes should have the same degree.

- In small breasts, the cement plaster solution is applied to the vertical planes of the sloping of the windows, and is leveled with a wooden fabric with a bent pen. To increase the surface strength, a reinforced mesh of fiberglass No. 80 or No. 100 is laid.

- The alignment of the last layer is made using a straight rail and grinds with a polyurethane grater. After drying, the slopes are putty with acrylic putty, polished by a grid grater and painted with water -based paint.

Installation of plastic window slopes

- The task for performing plastic window slopes with your own hands is difficult, but fulfilling. High accuracy and attentiveness when marking in installation is required. PVC panels and the assortment of profiles for them are usually used. A big plus of such panels - there is no need to paint them.

- Beautiful slopes yourself from plastic, with good dexterity, can be mounted in two to three hours. The panels are cut with a sharp mounting knife for drywall according to precisely verified sizes. For fastening, silicone -based glue is used.

- Alternatively, you can make a context of a rail, and then attach the mounting profile corner and panels on it with small screws - self -tapping screws.

- Voids are filled with mounting foam or mineral wool. If you have chosen the mounting foam, then at the time of polarization, make sure that there are no distortions. Weak and moving areas can be fixed with painting or technical adhesive tape.

For slopes made of plastic, choose panels resistant to ultraviolet and mechanical damage. For this, there are reinforced panels on sale, with a strong facial layer and even with cavities filled with polysterol. There are more information about the installation and decoration of window openings in the video.

For slopes made of plastic, choose panels resistant to ultraviolet and mechanical damage. For this, there are reinforced panels on sale, with a strong facial layer and even with cavities filled with polysterol. There are more information about the installation and decoration of window openings in the video.