Metal -plastic windows today are in unprecedented consumer demand. They are not expensive, in comparison with wooden double -glazed windows, durable and well isolate the room from extraneous sounds, dust and winds.

Content

But one proper installation of plastic double -glazed windows is not enough, often a real problem for the population is the design of a window opening, that is, the finish of the slopes of plastic windows. Many resort to the help of professional plasters, but such work is quite capable of doing it with their own hands without special skills.

Types of finishing slopes

Slopes are the surface of the walls near the windows. In turn, they are internal, that is, in the room, and external - on the street. Looking neatly window slopes should be not only from the point of view of aesthetics. This is a mandatory requirement from the point of view of maintaining heat in the room, the finished slopes prevent fogging of the windows, and the mounting foam closed in this way will not be supplied with moisture destructive for it.

Slopes from plaster

The slopes are most often plastered. First, a layer of primer is applied, after its drying - several layers of the plaster mixture (it can be purchased at any construction store) until the slopes are completely even. When the plaster dries, it must be disconnected and painted.

The correct implementation of this procedure will take about a week, or even more. The disadvantage of the slopes from the plaster is their fragility. Over the years, the plaster turns yellow and cracks.

Slopes made of drywall

The second most popular method of plastic windows inside is the lining of window openings with drywall. It has good heat -insulating properties, it can also be insulated. If you know the technology, then you can attach slopes of drywall in a few days, unlike plaster slopes.

On a sheet of drywall using a jigsaw, a measured length and width suitable for slopes from all sides are cut out on top and on the sides. The emptiness between the wall and the leaf is filled with polyurethane foam, and the drywall itself is attached with dowels. At the same time, a little space should remain between the gypsum cardboard and foam. The upper slope is attached in the same way. Three hours after the foam harden, all joints and cracks are covered with a solution of putty. Metal corners are attached to protect the cuts.

The surface of the drywall is aligned with putty and grinds after drying. Then it must be primed and painted.

The drywall is durable, but it is impossible to fix it in a room with high humidity because of its instability to moisture. Otherwise, you need to purchase a moisture -resistant drywall.

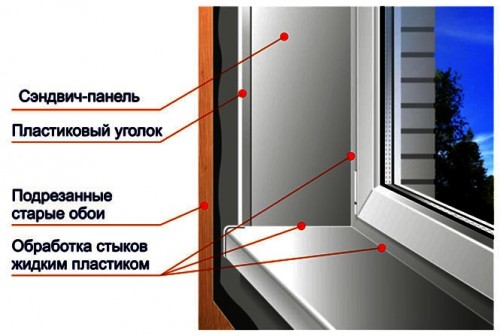

Slopes from sandwich panels

The finish of plastic windows with sandwich panels is performed easily and quickly. Such panels are several layers of plastic, between which there is a polyurethane insulation. Such panels are easy to install with your own hands, they do not require care, is well isolated noise and are resistant to weather changes. Before fastening, sandwich panels are measured parameters of slopes along which stripes from panels are cut: side and one upper.

- An excess mounting foam is cut off with a construction knife. Self-tapping screws along the edges of the window profile are attached to the launch profile of the P-shaped.

- The upper leaf of sandwich panels is inserted into the grooves of the starting profile and mounted with self-tapping screws.

- On both sides of the window openings, to the existing profile, 4 more parts of the profile are attached with self -tapping screws. Sandwich panels are applied to them.

- On the edge of the window openings, an overlaid on the sandwich panel is attached to a F-shaped profile, forming neat corners.

- If you get uneven joints, they can be treated with liquid plastic.

It is worth noting the advantages of finishing plastic windows with sandwich panels:

- resistant to sunlight, do not burn out and do not yellow;

- the design of the panels allows you to finish the slopes at any angle;

- have good soundproofing properties;

- save heat and do not require additional care.

Spear plastic slopes

The most simply perform finishing work of slopes with cell plastic or panelite. It is glued to the surface of the slope.

The simplicity of use lies lies with a number of disadvantages of this type of slopes. Firstly, it is important to use a more expensive and high-quality panelite. Secondly, before gluing the bands of plastic, it is necessary to additionally insulate the surface of the slope. If this is not done, the slope will freeze and form condensate. In addition, cellular plastic is limited in width, no more than 25 cm.

Plastic slopes

Plastic slopes are mounted quite quickly. Outwardly, they are attractive, do not burn out in the sun and simply wash themselves from dirt. When installing plastic slopes, mineral wool is used for insulation. Such slopes can be performed without outside help.

Window decoration materials

For finishing the window with plastic panels you will need:

- plastic. Its length should be 6 m, and the thickness is 8 mm;

- P-shaped plastic strip;

- drill;

- building scissors, knife;

- insulation (mineral wool is suitable);

- level (construction);

- wooden rails (about 1.5cm thick);

- stapler for fastening plastic;

- self -tapping screws;

- white silicone.

Rules for installing plastic slopes

In order to correctly fix the slopes of plastic, it is important to observe the following order:

- When the double -glazed windows are already set, plastic profiles with grooves are attached to the side walls along the slopes, where plastic panels will subsequently drive.

- Using self-tapping screws, a P-shaped plastic strip is attached, along the outer perimeter of the window. Thus, to get a groove.

- The F-shaped strip is attached parallel to the P-shaped groove using a stapler.

- The measured plastic stripes are installed in grooves, and cotton wool is laid between the wall and the plastic.

- At the end of the window finishing with plastic panels, white silicone, you can obscure places where the joints did not coincide a little.

When decorating plastic windows, it is important to reliably waterproof mounting seams. It is known that with prolonged contact with the external environment, the installation foam is destroyed, it loses its thermal insulation properties and over time the double -glazed window can be tilt. Therefore, in any case, it is necessary to carefully isolate the foam from harmful effects. A neatly finished plastic windows will give them a pleasant and aesthetic look.

External decoration of plastic windows

The outer decoration of window slopes can be performed in the following ways:

- The most popular and inexpensive way of decorating plastic windows outside is plastering. Having only a dry cement mixture in your arsenal, you can quickly cope with finishing work. And for this, experience in construction is completely optional.

In order to independently plaster the outer slope of the plastic window, it is important to observe the following order:

- with the help of a knife, it is good to trim the protruding construction foam from the surface of the slope and remove the dirt. Check the evenness of the slopes using the level. You can start plastering walls with a mixture based on cement and gypsum with water;

- additional insulation of slopes is not required, mounting foam and so it is a heat insulator;

- the layer of the plaster mix should cover the window frame for one and a half centimeters and completely close the foam;

- a wooden bar is distributed a plaster layer. The corners are wiped. When the last layer of plaster dries, the slopes can be painted.

- Plastic windows tape psul

The abbreviation Psul is deciphered as a polyurethane self -expanding sealing ribbon. This newfangled foreign invention can reliably protect mounting seams from moisture, sunlight and frost. Having completed the finish of the slopes with such a tape, it expands, filling the free space.

From the shortcomings of the psul, we can highlight that this tape can not always be purchased in stores.

In addition, if deep potholes are found during the installation of double -glazed windows, then the psul tape will not help to carefully finish all the irregularities. It is also not desirable to paint and process the surface of the tape.

- Roading slopes with steamers

It is easiest to finish plastic windows with your own hands with the use of the so -called hills. These are self -adhesive laminated or plastic strips that remarkably hide all the defects left after the installation of windows. Straps are of different widths and colors. They qualitatively close the slopes and mounting seams from frost, moisture and temperature changes. It is only important to correctly cut and fit the traps to the size of the window. In addition, this is a very inexpensive building material.

Squinting of slopes

As a rule, window slopes need insulation, when the room itself was not sheathed with a heater even when it is built. If there is an acute need to insulate window slopes inside, this can be done with your own hands using ordinary foam.

Stages of insulation window slopes:

- foam blocks, about five centimeters thick, must be cut with a construction knife with a width, which should be less than the width of the slope per centimeter;

- on a pre -placed slope, it is necessary to plant foam sheets using the mounting foam. The foam must cover the mounting seam;

- the joints between the sheets of foam and profile are also filled with foam;

- then the heater made of foam is sheathed with drywall. It can be plastered and painted.