The construction of any house begins with the construction of the foundation, and if you decide to choose a musculoskeletal foundation, first you need to study all the nuances before starting work.

Content

General characteristics

Most people choose this particular type of foundation due to its low cost. The price of a supported foundation is several times less than any other monolithic type. Another advantage is that such a foundation can be easily built with your own hands in the presence of elementary skills in handling building materials.

Shipping foundations can be erected on any type of soil, even on heaving soils. This is a universal design, which differs in long life and does not require the conduct of costly heat -insulating and waterproofing work.

Varieties of supported foundations

The material from which you will build a musculoskeletal foundation with your own hands must be selected already at the design stage.

Depending on the material, the foundations can be divided into the following types:

- concrete;

- bottle;

- butta-sequence;

- brick;

- stone.

In some cases, strong wood species are chosen for construction, however, a wooden column foundation requires special treatment with solutions that protect against decay and corrosion.

The most common types of columnar foundations are made of brick and concrete. These are monolithic structures that are not subject to corrosion and have long life. A brick column foundation will easily stand for about a hundred years, however, this type also has its small flaws.

Disadvantages of a brick foundation:

- the complexity-the construction of a supported foundation, judging by the reviews, will require more effort and time than the construction of any other type;

- the risk of deformation - if your site is on highly fluffy soil, it is better to bypass the concrete or stone, because the brick structure may not withstand the offset of the soil;

- financial costs - for the construction of a brick column foundation, it is necessary to purchase a high -quality burnt brick, otherwise the foundation will not last long.

Also, columnar foundations can be divided by the degree of deepening into the soil:

- shallow-laid to a depth of 50-70 cm in soils with a fairly low level of groundwater;

- runned - relevant for wet heaving soils. Such a foundation must be pumped to a depth of at least two meters.

How to make a supporting foundation

The construction of any foundation should be carried out on pre-prepared soil, and the musculoskeletal type is no exception.

The following main stages can be distinguished by the construction of a supported foundation:

- Preliminary preparation of the site for development. Remove all the garbage from the territory and align all the bumps (hillocks, pits, etc.). If your site is located on clay soil, it is necessary to provide gravel adding.

- Marking the construction site. Mark the location of each pillar of the future foundation with the pegs. Earthwork can be carried out on its own or with the help of a tractor or an excavator, if there is such an opportunity.

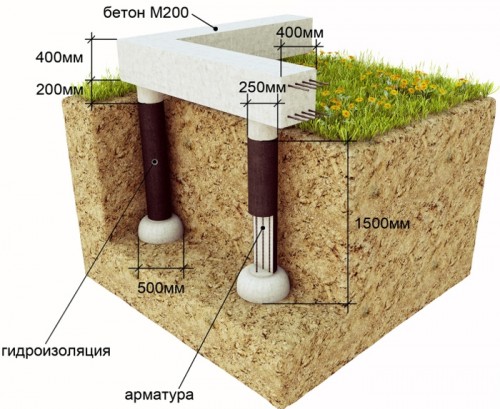

- Installation of pillars. If the pillars of your foundation are quite short and do not exceed the meter length, it is not necessary to strengthen the recesses dug under them. If the pillars are long, then it is necessary to drill a well expanding to the top, and then install in each of them several spacers of boards or bars. In order to guarantee to protect the future building from drawdown, it is recommended to make a reinforced concrete “pillow” at the bottom of the pit.

- Production of formwork. The formwork structure is made of boards with a width of 15 cm with a thickness of 4 cm. To perform non -removable formwork, it is necessary to build shields from asbestos -cement pipes, the diameter of which will be more than 10 cm.

- Reinforcing the foundation of the foundation. In order to reinforce the columnar base, it is necessary to purchase reinforcement with a cross section of 12 to 14 mm. The rods should be installed in a longitudinal way using a strong wire to create horizontal jumper. It is recommended to leave the ends of the reinforcement with a length of up to 20 cm with not flooded solution. This is useful for a convenient bunch of pillars with a grillage.

- When the reinforcement is connected, it is time to fill the foundation with concrete solution. In order to prevent the formation of voids during pouring, try to compact the mixture as tightly as possible. High -quality waterproofing will also not be superfluous, especially if the house is built on wet soils. As a waterproofing material, a roofing material is perfect in two layers. For normal and dry soils, one layer of waterproofing will be enough.

- Construction of a grillage. The grillage is the upper part of the foundation in the form of a slab or grille, the main task of which is to uniform distribution of the load over the entire area of \u200b\u200bthe foundation. For the construction of a grillage on a supporting foundation, make a frame from the reinforcement, connecting the jumpers using the same reinforcement. After creating the frame, install the formwork structure and pour concrete into the resulting form. After the concrete hardening, the grillage will be ready.

- The final stage - laying a brick layer. During work, do not forget to leave openings for communications and ventilation. When erecting walls of brick or foam blocks, do not install elements directly on the pillars, otherwise distortions and cracks may occur.

The foundation of pipes

Many people prefer to build a point, musculoskeletal foundation from pipes, because this method takes less time and does not require any specific skills.

Stages of construction foundations from pipes:

- drill a well for the foundation, the bottom is thoroughly tamped;

- increase the pipes in a diameter of the well in the hole of the well;

- ensure reliable fixation of the pipes in an upright position, falling asleep with dense soil;

- pour the interior of the pipes into a third with concrete solution, raise the pipe up so that the solution fills the vacant space;

- pour the solution into the pipe again, leaving only 10-15 centimeters empty in the upper part of the pipe;

- diminate the concrete mixture in the pipe with a bayonet method, installing a reinforcing rod in the middle of the pipe;

- after a complete solidification of the solution, knit the foundation, attaching the anchor elements to the lower edges of the walls of the walls and plunging them into the pipes that are unsolved with cement;

- thoroughly concrete the foundation.

Superficial type of foundation

A surface, musculoskeletal foundation is suitable for small buildings made of wood, timber or frame houses in size not exceeding 6x6 meters. This type is a foundation for the construction of which monolithic concrete cabinets are used.

A surface foundation can be built on sandy or coarse -luminous soil. Pillars are installed at the corners of the house, where the internal walls intersect with the outer ones and at the points where heavy supporting pieces are installed.

Fundamental supports are powerful concrete blocks, the number of which is determined by the characteristics of the plan of the future home. From 4 to 6 blocks, interconnected using a cement mortar, goes to each support. The sizes of blocks are standard - 200x200x400 mm.

There are a number of restrictions for the construction of a surface column foundation from blocks:

- this type of foundation is strictly not recommended to be built on wet and heaving soils or “weak” soils (clay, peat);

- the block foundation will not withstand a massive structure;

- it is difficult to cite the basement under the house erected on the column foundation.

As a rule, surface column foundations are chosen for the construction of baths or everyday life. The construction is quite simple, cheap and does not require additional waterproofing.