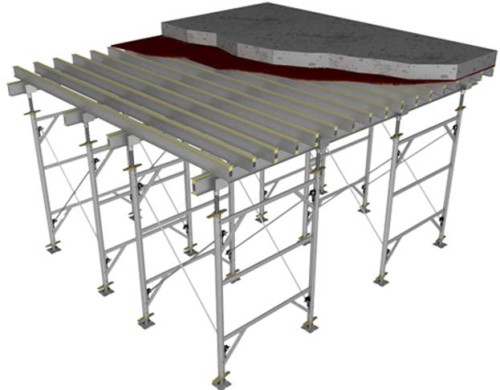

The formwork in construction is used not only for the construction of the foundation, concrete walls or collectors. It is successfully used for reinforced concrete floors of various thicknesses and purpose. Monolithic ceilings have proven themselves quite well in terms of strength, reliability and economy. In cases where it is impossible to install the finished floor plate on a box of capital walls, a monolithic ceiling is made in place by a bulk method. Overlap for the lower room will be the base of the ceiling, and for the upper base of the floor.

Content

To create a strong reinforced monolithic overlap from reinforced concrete, a profile formwork will be required. Before starting work on the construction of the formwork of the ceilings, sizes and the harvesting of materials are made. In the process of preparing the drawings, communication holes are taken into account for plumbing and heating pipes and power supply routes. The arrangement of the formwork of ceilings requires meticulous observance of the technology at all stages, from the installation of formwork to filling and drying concrete. The final result and the qualitative characteristics of the ceilings depend on this.

Tools and materials for arranging the formwork of ceilings

Formwork for monolithic ceilings are made collapsible or non -removable. Any of them will require a certain set of materials. The number, dimensions and volumes are determined on the basis of the drawing of the overlapped surface.

- For the base of the formwork of the ceiling, it will require waterproof plywood at least 2 cm thick, corrugated board or OSB sheets with waterproof impregnation.

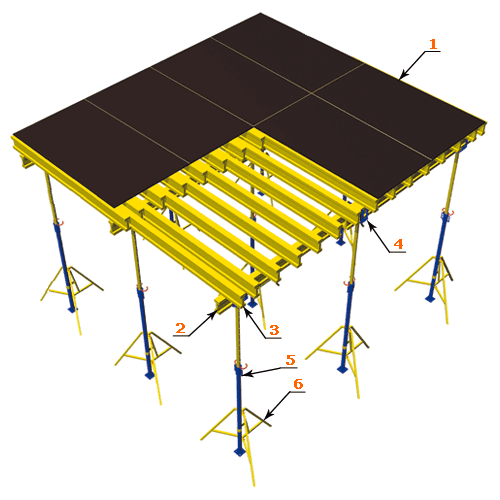

- Telescopic support racks with a threaded or pneumatic lifting system. Sometimes ordinary car jacks or deaf unregulated supports are used.

- Metal, wooden or reinforced concrete beams. Their parameters are determined by the area of \u200b\u200bthe overlapped space. According to the profile, the formwork beams are used by the outbuildings of the I -beam, the channel or other configuration.

- Concrete overlap reinforcement is carried out by steel reinforcement with a diameter of 8 - 10 mm, a knitting wire or weld is used for fastening.

- A high -strength brand of 400 or 500, sand, gravel and with large volumes of work, a concrete mixer, will be required. During the work, a normal set of construction tools will be required: shovel, Kelma, Kirochka, turbocharging machine, Waterpas, etc.

Calculation of installation of racks for formwork of ceilings

The formwork is calculated taking into account data on the height of the room and the thickness of the bulk reinforced concrete overlap. The exact dimensions of the equipped area will correctly distribute the loads on the plane and distribute the supporting elements in accordance with the technological requirements.

- The racks of supports have standard dimensions from 1.7 to 4.5 meters. When installing at the rate of 1 stand for 1 sq.m. - The loads are evenly distributed, and the required margin of strength is provided. With a thickness of the ceiling 40 cm, the load on the rack will be 1,500 - 2000 kg, which meets the technological requirements.

- The stability of the racks for formwork of the floor is ensured by tripods, which is equipped with each stand individually. The upper part is equipped with univils, and jacks are provided for sliding telescopic racks.

- The estimated length of the beams attached by means of univilles is 3.5 linear meters per 1 sq.m. Plywood sheets, have dimensions of 1220x 2440 mm and to determine the required amount, the area of \u200b\u200bthe overlapped space is divided into the area of \u200b\u200bthe plywood sheet.

- When arranging a monolithic ceiling at a level above 4.5 meters, the racks are equipped with connecting horizontal crossbars. Two types of crossbars - a wedge or a cup/lock, ensure the stability of the structure.

Installation of non -removable formwork of monolithic floors

The best option for pouring concrete is a non -removable formwork of ceilings. This design is characterized by reliable spinning of walls and ceilings. The rods of reinforcement and blocking beams fall directly on the capital walls and provide the necessary rigidity of the structure.

- Sheets of plywood or other material are laid on the capital walls, which will serve as a bottom of the formwork and beams. For the beams, a channel, double as is used, wooden logs or concrete pillars and they are attached tightly to the capital walls with bolts or brackets. On below, the unit's support racks are installed which rests on beam floors. Along the perimeter of the capital walls of the laid out, for example, a side of half a brick is built in three bricks.

- The space is blocked by longitudinal and transverse reinforcement. At the intersection points, the reinforcement is grabbed by welding or knitting wire. The ends of the reinforcement should go to the plane of the capital wall and rest against the side. Then the next layer is laid out in half a brick and interspersed with reinforcement from the reinforcement, and so on until the calculated thickness of the monolithic floor is reached.

Concrete is poured at a time and racley is aligned. Raklya is a device similar to a mop. Depending on weather conditions, concrete is covered with a film from the rain or moistened in hot weather for uniform drying. For the final drying of the overlap, it will take at least a month.